Green Energy: Agrimin delivers 84pc renewable energy penetration at Mackay Potash Project

Mining

Mining

Agrimin Ltd (ASX:AMN) has delivered an 84pc renewable energy penetration rate through Front End Engineering Design (FEED) work at its Mackay Potash Project — around 785km from the Port of Wyndham in Western Australia, the company said this morning.

The FEED power solution underpins Agrimin’s low-carbon sulphate of potash (SOP) production and supports its transition to net zero emissions at the project.

After completing the definitive feasibility study (DFS) in July 2020, the potash company set out to complete long-term wind monitoring at the proposed processing plant site, which AMN said provided “excellent” results with an average speed of 27km per hour and low seasonal variability.

The data also indicated higher wind velocities at night, complementing the solar energy that is available during daylight.

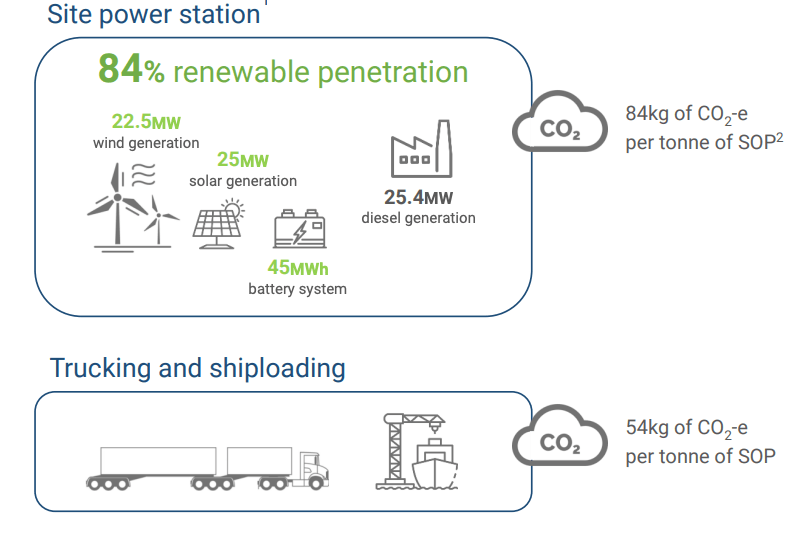

Agrimin worked with its proposed power contractor during the FEED phase to refine Mackay’s power station design, which resulted in a hybrid diesel, solar, wind and battery solution with a modelled renewable energy penetration of 84%.

This power station will support the processing plant, no process infrastructure, offices and accommodation camp, as well as salt harvesting and pumping operations within the solar evaporation ponds.

The DFS assumed that the project’s power station will be delivered under a build-own-operate contract.

Under this same delivery assumption and based on an updated indicative proposal received from the same power contractor, there has been no material change to the estimated cost for power compared to the DFS estimate.

Beyond the FEED phase, Agrimin will increasingly investigate renewable energy storage options (including hydrogen technology), to further reduce greenhouse gas emissions during the Mackay project’s 40-year life.

AMN’s joint venture haulage operator, Newhaul Bulk, is also setting out to evaluate hydrogen-powered road trains as this technology advances.

Production will have low emissions of 138kg of CO2 per tonne of SOP, inclusive of trucking and ship loading, the company said.

Of these emissions, Agrimin said 84kg per tonne relates to all site-based power generation.

Another 54kg per tonne relates to product trucking and ship loading, while the project’s scope 1 and 2 emissions have reduced to around 63,000 tonnes per annum of CO2.

The company’s DFS has demonstrated economics with a post-tax real NPV (net present value) of US$655 million, and IRR (internal rate of return) of 21pc, based upon a total cash cost of US$159 per tonne free on board (FOB) and a flat SOP price of US$500 per tonne.