Sovereign Metals showcases Kasiya graphite potential to UK parliament

Mining

Mining

Sovereign Metals has presented the potential for its Kasiya Rutile Project in Malawi to become an important supplier of low carbon-footprint natural graphite to members from both sides of the UK Houses of Parliament.

The company presented to a Roundtable on behalf of the All-Party Parliamentary Group (APPG) for Critical Minerals – whose purpose is to highlight the UK’s need for a secure, sustainable supply of critical minerals to deliver the nation’s industrial strategy which has since transitioned into the Plan for Growth: “Build Back Better.”

Notably, a recent Life Cycle Assessment Study (LCA) concluded that the production of natural graphite by-product from Kasiya is expected to have a substantially lower Global Warming Potential (GWP) compared to natural graphite produced in China.

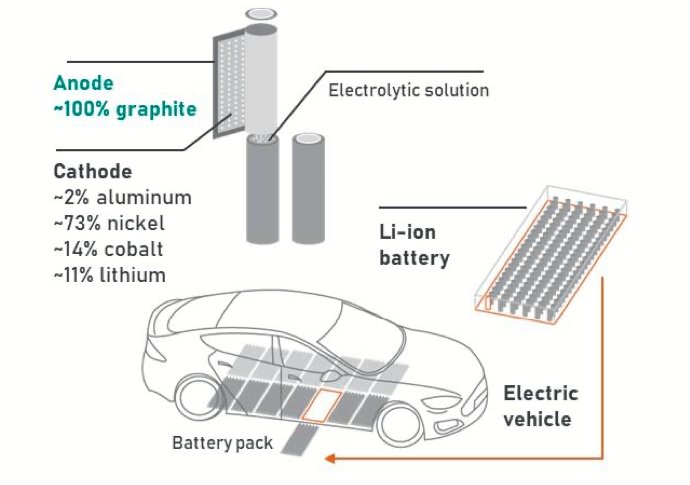

The lithium-ion battery sector is the main emerging market for flake graphite and greater capacity batteries, such as those required for electric vehicles, are expected to drive significant demand for graphite over the coming years.

It is forecast the battery sector will drive the largest demand for graphite by 2028, with graphite making up to 50% of the composition of a lithium-ion battery.

And Kasiya’s graphite characterisation shows a coarse flake, high purity and highly crystalline product which the company says should be suitable for lithium-ion batteries and wider industrial uses.

“The importance of sustainable supply chains for clean-tech solutions such as lithium-ion battery powered electric vehicles cannot be underestimated,” Sovereign Metals (ASX:SVM) chairman Ben Stoikovich said.

“As such, Kasiya could become globally strategically important as it has the potential to supply not one, but two, critical raw materials to world economies looking at building a sustainable future and tackling climate change.”

China currently produces over 75% of the world’s natural graphite, almost 80% of the world’s synthetic graphite and 100% of the world’s natural graphite anodes used in lithium-ion batteries.

But hard-rock ore production requires drilling, blasting, excavation, trucking, crushing and grinding – overall high CO2e activities.

Whereas Kasiya’s graphite is hosted in soft, friable saprolite material which will be mined via hydro methods (high pressure water monitors) powered by renewable energy sources – hydro power from the Malawi grid and on-site solar power.

And each tonne of graphite produced from Kasiya is expected to have a Global Warming Potential of only 0.2 tonnes CO2e – which represents 80% lower greenhouse gas emissions compared to natural graphite produced in China

This article was developed in collaboration with Sovereign Metals Limited, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.