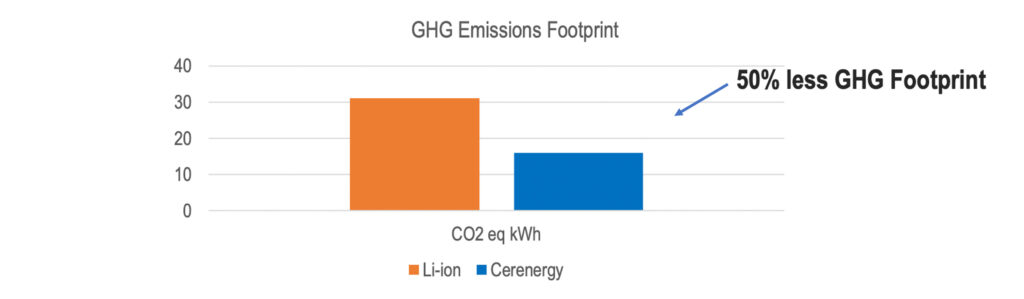

Altech’s revolutionary battery technology has 50% less emissions than lithium-ion

Tech

Tech

Studies indicate Altech’s Sodium-Chloride Solid State CERENERGY® batteries benefit from a far lower greenhouse gas (GHG) footprint than that of lithium-ion batteries.

The company has now engaged the Centre of International Climate and Environmental Research (CICERO) for a green accreditation of the CERENERGY® battery and project.

CICERO, renowned for its expertise in providing independent evaluations for green credentials, previously gave Altech a “Light Green” rating for its Silumina Anodes project.

Altech (ASX:ATC) also initiated a separate ESG reporting process, during which it quickly became apparent that many of the key metrics were already in place.

They simply needed to be organised within a visible framework to effectively communicate with stakeholders.

“The significance of ESG reporting is underscored by the fact that 82% of retail investors express interest in investing in socially and environmentally responsible companies,” the company says.

“Furthermore, 9 out of 10 institutional investors now incorporate ESG factors into their investment decision-making processes.”

The importance of efficient energy storage systems, such as grids storage batteries, is growing rapidly as the world transitions towards renewable energy sources.

Altech is exclusively targeting this sector with its revolutionary sodium-chloride solid state CERENERGY® batteries.

While lithium-ion currently dominates the emerging grid storage sector, sodium-chloride blows it — and other battery types — out of the water on several crucial metrics, including cost and emissions.

A University study indicated that the GHG emissions of CERENERGY® batteries average 16g CO2eq per kWh discharged and consumed, compared to 31.3g CO2eq for lithium-ion batteries and 122.1g CO2eq for lead-acid batteries.

That’s a huge difference, which aligns with the fact that CERENERGY® batteries do not rely on critical metals such as lithium, cobalt, copper, graphite, and manganese, which are associated with high emissions from mining and extraction.

Instead, CERENERGY® batteries employ sodium-chloride (common table salt) and nickel.

Altech’s planned 100Mwh battery plant in Saxony, Germany, has been meticulously designed to minimise GHG emissions.

The entire factory will completely abstain from natural gas usage, for example, with the tunnel kiln utilised for sintering the ceramic tubes to be powered by electricity instead.

The site’s total power requirement is ~5MWh, and negotiations are underway to secure a renewable power supply for the facility.

The plant is also designed with an expansive factory roof space dedicated to housing photovoltaic panels.

To optimise energy usage, the plant employs multiple banks of 1 MWh GridPacks to store excess energy during the day for use during nighttime hours.

Unlike many battery makers who rely on third parties, a recycling facility will also be integrated at Saxony as part of a “cradle to the grave” approach to battery production.

Altech says this recycling plant will have the capability to recycle both off-spec battery units and returned battery units from the field.

“There is clearly an environmental advantage of the CERENERGY® battery and proposed factory,” Altech Managing Director Iggy Tan says.

“Considering the GHG footprint evaluation conducted by independent groups, we anticipated from the outset that our batteries would be classified as ‘green batteries.

“We are currently in the official accreditation process.”

This article was developed in collaboration with Altech Batteries, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.