This Aussie explorer is seeing the benefits of the US’ push to compete in battery metals

Pic: Tyler Stableford / Stone via Getty Images

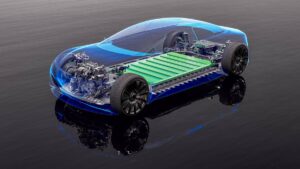

Special Report: Public and private sector interest in US lithium and the broader battery supply chain has been taken to a new level with proposed new legislation.

One senator wants to introduce legislation that protects not just the US’ mineral resources but also the supply chains that refine the raw materials into speciality, engineered materials for lithium-ion batteries and electric vehicles.

“Last year, we imported at least 50 per cent of 48 minerals, including 100 per cent of 18 of them,” Senator Lisa Murkowski said.

“That should worry everyone, particularly because it is happening at the same time that demand, for everything from graphite and lithium to cobalt and nickel, is about to skyrocket.

“I have introduced the American Mineral Security Act, a bipartisan bill that takes a comprehensive approach to rebuilding our domestic mineral supply chain. Unless we take significant steps, we’re at risk of ceding major economic drivers to other countries.”

The US’ intense focus on its domestic battery supply chain has led to early positives and promises of other benefits for junior players like emerging lithium-boron producer ioneer (ASX:INR).

ioneer is rapidly advancing its low-cost Rhyolite Ridge project in Nevada.

At full capacity the mine will produce 20,000 tonnes of lithium carbonate and ioneer’s goal is to be in production by mid-2021.

“There are moves to streamline permitting processing, we’ve already been seeing that,” managing director Bernard Rowe told Stockhead.

“This designation of critical minerals that President Trump introduced awhile back started the ball rolling in terms of streamlining permit process times and requirements, and our project has certainly been a beneficiary of that.

“We are seeing fairly rapid development of our permitting.”

Level financing playing field

Another emerging benefit of the US’ push to be a contender in the battery metals industry is the promise of a more level playing field when it comes to financing.

Financing is a big hurdle to the development of any project, but it is particularly hard when it comes to lithium projects because the market is rapidly growing and relatively opaque.

Following the Benchmark Minerals Summit in Washington recently, ioneer chairman James Calaway said there is an uneven playing field for the funding of lithium projects. Asian countries, in particular, have provided massive subsidies and other support for the emerging lithium-ion battery industry, while the US relied on pure free enterprise.

The US has the government agencies with the capability to provide funding for strategic projects but don’t have the budget, while Asian governments have provided their agencies with massive resources to participate in this industry of the future.

This has placed the US at a competitive disadvantage and resulted in a more expensive cost of capital to develop American projects as US lithium projects are more reliant on bank financing to come to fruition.

“I think it is about an increased awareness that there does have to be production in the United States and if there has to be production, then there also has to be financing to allow that to happen and that’s where the government can play a role in that,” Rowe said.

“It’s about clearing the pathway for development, lowering the risk of development of these projects as best they can, so that financing becomes available at rates that are more comparable with other parts of the world.

“Things like making investment into these projects from a tax point of view more attractive.”

‘Global battery arms race’

Simon Moores, managing director of Benchmark Mineral Intelligence, said the world is in the middle of a “global battery arms race” that is intensifying.

“Lithium, graphite, cobalt and nickel are the key enablers of the lithium-ion battery and, in turn, the lithium-ion battery is the key enabler of the energy storage revolution.

“Globally, they are facing a wall of demand especially from electric vehicles, yet the US has been a bystander in building a domestic supply chain capacity.

“Right now, the US produces 1 per cent of global lithium supply and only 7 per cent of refined lithium chemical supply, while China produces 51 per cent.”

The US currently only produces about 4,000 tonnes of lithium carbonate, but the battery factory capacity already slated for the country is about 60-70 gigawatt-hours, which requires about 50,000 tonnes of lithium carbonate.

That’s 12.5 times what the US currently produces.

- Subscribe to our daily newsletter

- Join our small cap Facebook group

- Follow us on Facebook or Twitter

This story was developed in collaboration with ioneer, a Stockhead advertiser at the time of publishing.

This advice has been prepared without taking into account your objectives, financial situation or needs. You should, therefore, consider the appropriateness of the advice, in light of your own objectives, financial situation or needs, before acting on the advice. If this advice relates to the acquisition, or possible acquisition, of a particular financial product, the recipient should obtain a disclosure document, a Product Disclosure Statement or an offer document (PDS) relating to the product and consider the PDS before making any decision about whether to acquire the product.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.