US push for a domestic EV supply chain is good news for this junior

Pic: Bloomberg Creative / Bloomberg Creative Photos via Getty Images

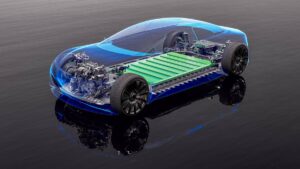

Special Report: News reports have emerged that the US wants to establish its own electric vehicle supply chain to not only boost its economy but also reduce its reliance on China.

The US wants to bolster its domestic supply of everything from raw materials through to the cathodes, the batteries and the EVs.

This is good news for any Aussie miner with a battery metals project in the US, but there is one junior that is particularly well positioned to take advantage of the new US EV industry push.

Emerging lithium-boron producer ioneer (ASX:INR) is rapidly advancing its low-cost Rhyolite Ridge project in Nevada.

At full capacity the mine will produce 20,000 tonnes of lithium carbonate and ioneer’s goal is to be in production by mid-2021.

“If the US is adamant about establishing its own EV supply chain, then you need proven technology that works at commercial scale and has the opportunity to be in production within a few years,” managing director Bernard Rowe told Stockhead.

“I think we are ideally positioned with regard to the lithium battery industry because we have an advanced project, we have completed a pre-feasibility study and the economics stand up for themselves.

“It’s going to take more than one deposit to supply the US market, particularly as the EV industry grows.

“We can see eventually multiple lithium deposits being developed in the US just to supply the domestic market, but we obviously also clearly think that ours offers by far the best opportunity in the short-term because of how advanced it is and the technology.”

US is going to need more lithium

Right now the US only produces a very small amount of lithium, courtesy of heavyweight Albemarle.

But Albemarle doesn’t supply that lithium to the domestic market.

This means the US has to import all of its lithium. It does so from Argentina, Chile, China and Russia.

The US currently only produces about 4000 tonnes of lithium carbonate, but the battery factory capacity already slated for the country is about 60-70 gigawatt-hours, which requires about 50,000 tonnes of lithium carbonate.

That’s 12.5 times what the US currently produces.

According to Reuters, global carmakers are planning to spend at least $300 billion on the development and procurement of batteries and electric vehicles, with more than 45 per cent of their budgets targeted at China.

The US accounts for about $39 billion of that, ranking it third in terms of EV investment, but over 87 per cent of that is expected to be spent in the US.

Lithium-ion batteries are a key part of the EV supply chain and China dominates, controlling over 60 per cent of the market, while all up Asia has about 90 per cent market share.

Ahead of the pack

ioneer is now powering ahead with a definitive feasibility study (DFS) and thinks it could potentially save as much as $US60m ($83.5m) on the cost of building its sulphuric acid plant.

The acid plant will also generate its own heat, steam and power, meaning ioneer won’t have to source and pay for power from the grid.

“Rhyolite Ridge is not something that requires a subsidy just to make it work,” Rowe said.

“The economics of the project are very robust in themselves.”

ioneer expects to have its DFS completed in the third quarter of this year.

Rhyolite Ridge is expected to be one of the lowest cost lithium projects and it is in the very mining jurisdiction that Canadian public policy think tank Fraser Institute just ranked number one.

Two EV products better than one

It’s not just the lithium that makes ioneer’s Rhyolite Ridge an attractive project, it will also produce boron.

>> Read: Boron is a $4bn market and this ASX small cap wants to be a player

Most people may not realise that boron has also worked its way into the EV supply chain.

One of the most common magnets made for electric motors is a neodymium-iron-boron permanent magnet.

“The quantity of boron in a magnet is much less than that of either iron or neodymium, but it is a growing market and China again dominates that area,” Rowe said.

The boron will give ioneer a second revenue stream.

Because the company will be able to produce 8 tonnes of boric acid with every tonne of lithium carbonate it produces, ioneer will be able to produce its lithium carbonate for less than $2,000 a tonne.

Boric acid fetches around $700 a tonne, with pricing remaining relatively steady because there are just two major players in the market.

This means the 8 tonnes of boric acid will contribute $5600 to ioneer’s bottom line, reducing its total production cost of $7,400 to just $1,800.

>> Lithium stocks guide: Here’s everything you need to know

- Subscribe to our daily newsletter

- Join our small cap Facebook group

- Follow us on Facebook or Twitter

This story was developed in collaboration with ioneer, a Stockhead advertiser at the time of publishing.

This advice has been prepared without taking into account your objectives, financial situation or needs. You should, therefore, consider the appropriateness of the advice, in light of your own objectives, financial situation or needs, before acting on the advice. If this advice relates to the acquisition, or possible acquisition, of a particular financial product, the recipient should obtain a disclosure document, a Product Disclosure Statement or an offer document (PDS) relating to the product and consider the PDS before making any decision about whether to acquire the product.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.