Sparc Technologies’ graphene product is a winner in metals recovery

Good catch! Sparc Technologies has demonstrated the utility of its graphene technology in metals recovery: Image: Getty

Sparc Technologies’ graphene technology has significantly outperformed competitor products in the recovery of precious metals including gold and silver.

Laboratory tests have demonstrated the utility of Sparc Technologies’ (ASX:SPN) graphene-based adsorbent technology solution in the recovery of precious metals from mining waste.

“We are excited to see results from initial testing that demonstrate our Sparc graphene enhanced adsorbents significantly improves the recovery of gold and silver in solution, which gives us the encouragement to progress to the next stage of testing at both operating and residual mines,” managing director, Tom Spurling, said.

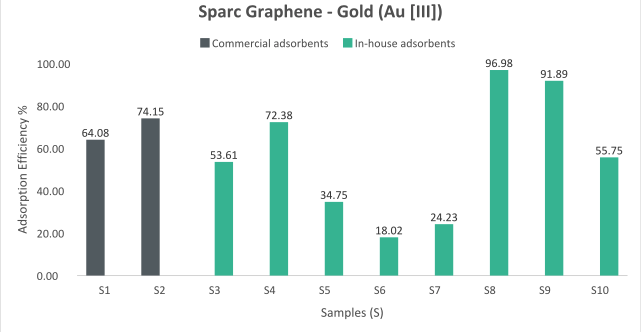

The laboratory tests for Sparc Technologies’ graphene product showed an adsorption rate of 96.98 per cent and 97.82 per cent in retrieving gold and silver, respectively.

These test results show the company’s graphene adsorption technology ‘substantially outperforms’ commercially-available adsorbents in treating mining tailings.

The graphene-based adsorbent technology can also be applied to oils and polyfluoroalkyl substances (PFAS), providing a solution for previously uneconomic or environmentally hazardous scenarios.

Company targeting $1 trillion metals recovery market

The ASX company is specifically targeting the market for retrieving precious metals from tailings at historical mine sites which is worth $US1 trillion ($1.26 trillion) globally.

Given the high demand for gold and silver globally, new recovery and recycling technology of the kind developed by Sparc Technologies is in high demand worldwide.

Australia is a significant exporter of precious metals and has ready-made customers for Sparc Technologies’ graphene technology that can improve the economics of existing extraction processes.

Sparc Technologies is to undertake further research work and trials to test its graphene technology solution for recovering precious metals from mine tailings.

The new graphene adsorbent technology is based on activated carbon which has higher capacity and adsorption rates in recovering precious metals.

Spurling said the laboratory results for its graphene product are “consistent with the significant improvement in performance that we are seeing in other projects being undertaken by Sparc with materials that are enhanced with graphene”.

Other applications for graphene technologies

The company has developed other applications for graphene-based technology including for the absorption of PFAS contaminants from industrial sites, and as a protective coating for ship hulls.

The company is developing new uses for graphene technology in partnership with the University of Adelaide, a cornerstone investor.

After its successful IPO and re-admission to the ASX in November, the company has appointed inventor and technology specialist, and former ResMed (ASX:RMD) senior executive Don Darkin as its strategic advisor.

This article was developed in collaboration with Sparc Technologies, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.