Sparc Technologies’ graphene coatings show improved product performance

Mining

Mining

Special Report: Graphene applications company Sparc Technologies has dramatically improved the anti-corrosion performance of protective coating products.

Test results for Sparc Technologies’ (ASX:SPN) marine protective coatings show they deliver improved product performance in terms of adhesion and anti-corrosion properties.

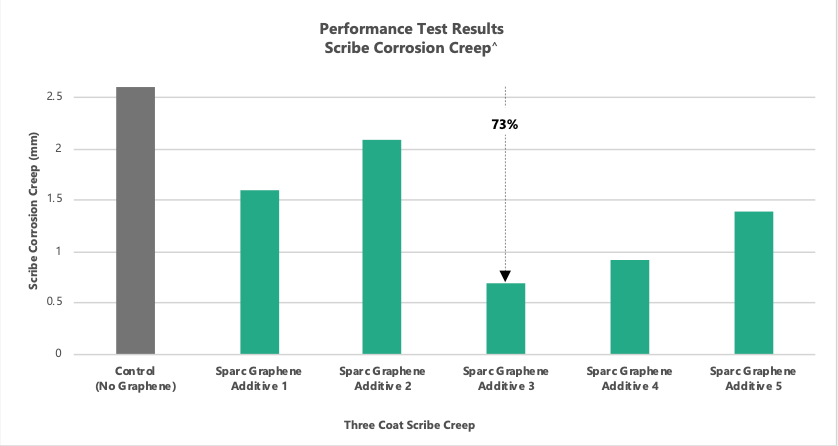

The tests showed a single coating of the company’s graphene-based product provided a 19 per cent improvement in adhesive performance, and a three-coat system resulted in a 73 per cent reduction in surface corrosion.

The research clearly demonstrated that even at relatively low levels graphene additives can significantly improve the performance of protective coatings products for marine and other applications.

The coatings tests measured variations in raw material sources, processing methods, and graphene quantities.

“The results from this round of test work are extremely encouraging,” managing director, Tom Spurling, said.

The laboratory tests were carried out to strict international standards by the University of Adelaide, Sparc Technologies’ research partner that also has an equity stake in the ASX company.

“Test work has been undertaken to conform to ISO standards which enables us to target our vast industrial customer base to assess the results objectively,” Spurling said.

The adhesion test included measuring the force needed to dislodge an object glued to a graphene coated steel surface.

Measuring the products’ anti-corrosion properties involved subjecting these to a 10-week period of changing climatic conditions, condensing moisture, and salt spray.

The graphene products were also sprayed onto steel panels as a surface layer that was scratched by a scribing tool to measure the extent of any resulting corrosion.

The less corrosion creep on the panel, the higher the coating’s resistance performance.

The results indicate that Sparc’s graphene-based products can deliver substantial cost savings and performance improvements to customers in the company’s target markets.

Results of adhesion and anti-corrosion tests for Sparc Techonologies’ graphene coatings products: Image: company supplied

The global market for graphene-based protective coatings for all types of uses is around $US16bn ($22bn), according to company data.

“Sparc will now use the data derived from this test work, build on it, and continue to refine the optimal graphene formulation for the coatings additive so as to maximise performance,” said Spurling.

The positive results mark a further milestone in the company’s development of graphene-based additives for application in the marine and protective coatings sectors.

In December, the company launched a bio-medical business headed by 20-year medical devices industry executive, Ben Yerbury.

The business unit’s first project is a graphene-based breath sensor for detecting illness in humans and animals through volatile organic compounds.

And, early last month, Sparc Technologies recruited former ResMed (ASX:RMD) executive and tech specialist Don Darkin as its strategic advisor for new technologies.

Darkin has extensive global experience in developing new technologies from early-stage development right through to commercialisation, and he is linked to 81 granted patents.

Sparc Technologies joined the ASX in November after raising $4m of capital through an IPO.

The company is focused on investigating three different market segments for the application of graphene-based technology.

They are marine coatings, metals recovery from tailings, and environmental remediation.

This article was developed in collaboration with Sparc Technologies, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.