Galan up with lithium heavyweights on 25pc recovery improvement

Mike Tyson, 20, delivers the knockout blow in his Heavyweight Championship fight against Trevor Berbick in 1986. Pic: AFP/Getty Images.

Galan Lithium has delivered a 25% improvement on initial lithium chloride concentrate grade estimates at its Hombre Muerto West (HMW) project in Argentina, granting it a result comparable to the industry’s heavyweights.

Latest testwork by Galan (ASX:GLN) on output from HMW delivered outstanding results, producing lithium chloride at a grade of 6% lithium, or 32% lithium carbonate equivalent, up from initial estimates of 4.8% lithium.

The result puts Galan in the ballpark of the industry’s South American heavy hitters – directly comparable to the grade of output produced by SQM and Albemarle from the Atacama Basin in Chile.

It represents one of the highest publicly known brine concentrate grades delivered by evaporation in the world.

HMW’s lithium chloride concentrate level of 12.92% is also equivalent to more than double the average concentrate grade of Australian lithium spodumene concentrate producers, which typically deliver at 6% lithium oxide – a factor Galan believes could give it a competitive advantage over hard rock producers.

Test results showed a very low level of contaminants, including sulphate, calcium and magnesium. Other elements, like potassium, sodium and chlorine are expected to be removed during the downstream treatment process.

The result was made possible through an optimisation process developed using the Ad-Infinitum prediction model – natural brine evaporation accelerated in a wind tunnel under controlled conditions

Galan managing director JP Vargas de la Vega said the results were exciting for the HMW project and the company.

“Grade is always king,” he said.

“These results are better than we envisaged and have more than solidified the serious potential of the HMW project.

“We have always followed the mantra of ‘walking before running’ and these results, whilst taking time to achieve, have affirmed our step-by-step approach of utilising proven technology with low risk in processing.

“Our teams in Argentina and Chile have been brilliant during these uncertain times and continue to deliver these essential project steps.”

The grades have the potential to give Galan exciting commercial opportunities with a lithium chlorine concentrate product.

What comes next

Galan said it would continue to test and optimise a range of lithium chloride concentrate solutions with conversion costs in mind, to deliver the best commercial solution in the shortest possible time.

The company expects to begin commissioning evaporation pilot testwork onsite during the second quarter of 2021 and will test the conversion of lithium chloride to battery grade lithium carbonate.

Galan is also in the process of reviewing the scope of work to find the most adequate path to accelerate project development to market.

“The high quality of the concentrated lithium chloride could be a major strategic differentiation for improving the economic performance of the project,” the company said.

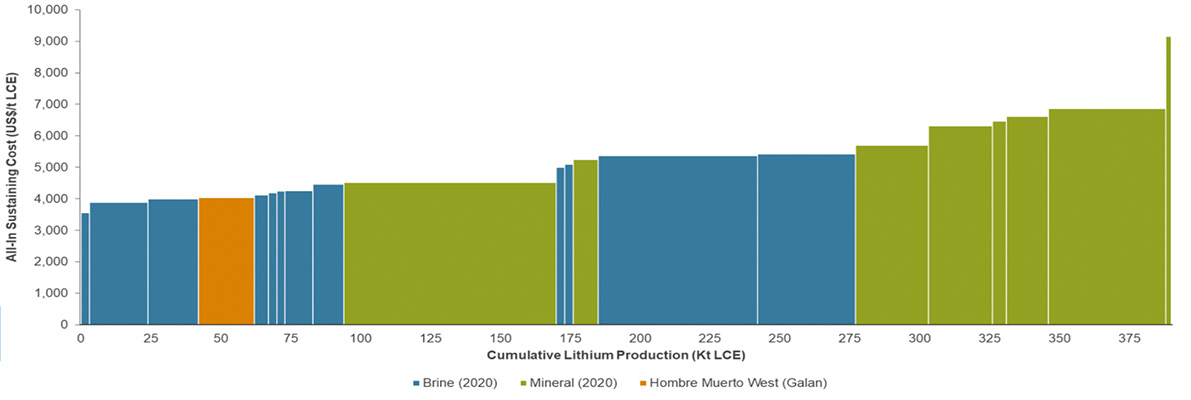

A recent study showed the project would produce lithium at about $US3518 per tonne – one of the lowest cash cost points in the industry – as highlighted in orange on the chart below.

Today’s results, borne of an optimisation study, have the potential to further improve this figure.

The company raised $10 million via a placement at the end of January, having bought into the Greenbushes South hard rock lithium project earlier that month.

This article was developed in collaboration with Galan Lithium, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.