First lithium carbonate produced at Green River opens pathway for Anson’s success

Anson Resources has reached another important milestone in the development of the Green River lithium project. Pic via Getty Images

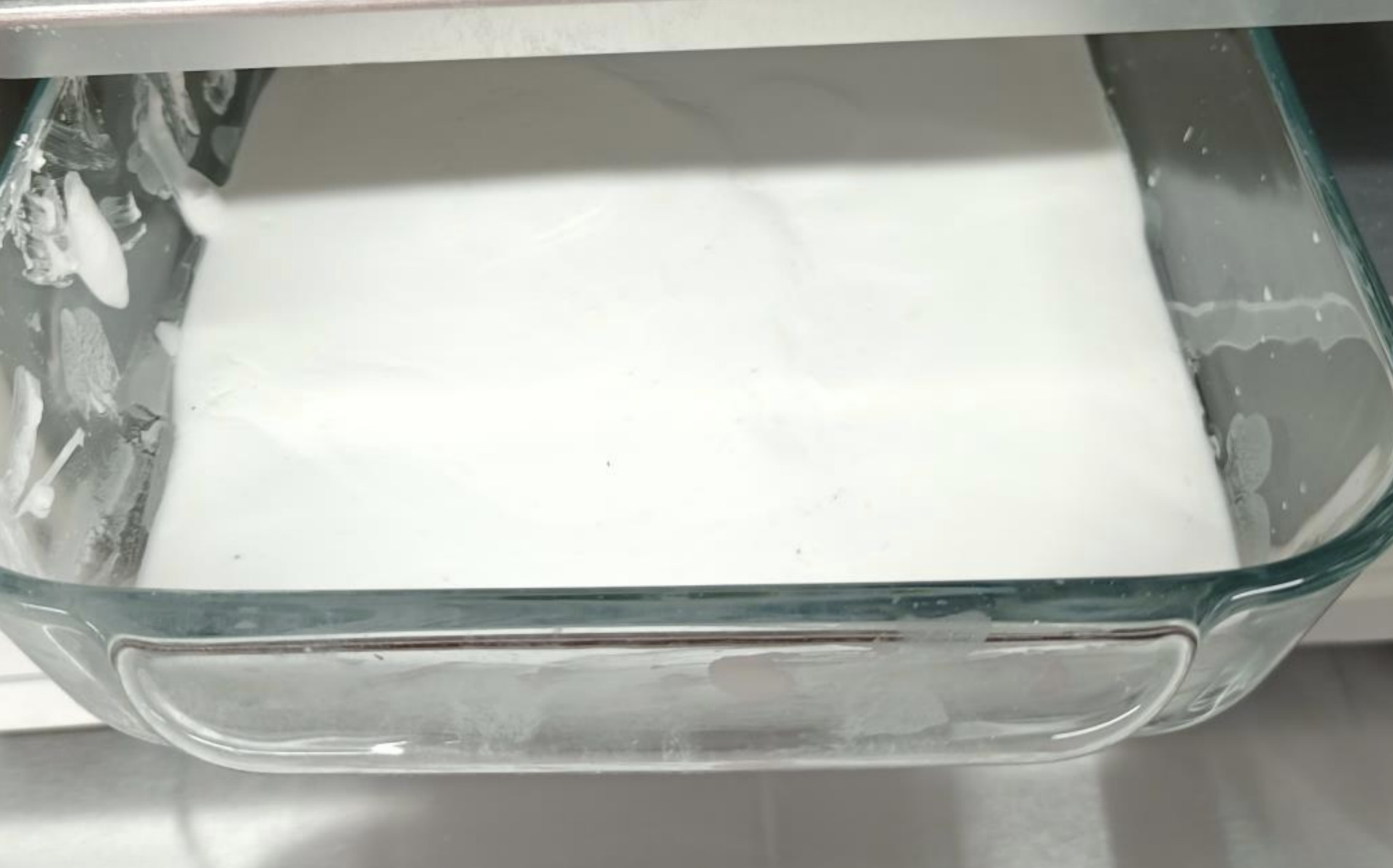

- Anson has produced its first lithium carbonate at the Green River demonstration plant in Utah

- Preparations for receiving fresh brine from the Boysdaba #1 Well have now been completed

- The demonstration plant is planned to run continuously for six months, producing battery-grade lithium carbonate with ongoing improvements to be made to the process

Special report: Anson has reached a new milestone at the Green River sample demonstration plant (SDP) following the production of lithium carbonate.

Anson Resources (ASX:ASN) staked the Green River project in Utah, ~50km northwest of the flagship Paradox project, in January 2023 with the intention of developing the site into a significant lithium producing operation.

Home to an exploration target of 2Bt–2.6Bt of brines grading 100ppm-150ppm lithium and 2,000ppm-3,000ppm bromine, ASN has been focused on proving up its resource base at Green River, which holds target clastic zones geologically similar to those at Paradox.

These clastic zones contribute 406,000t of contained lithium carbonate equivalent to the total resource of 1.5Mt contained LCE at Paradox, boasting a potentially lucrative development opportunity for ASN and the Green River project.

The company has already noted there is no connectivity between the deeper clastic zones and shallow aquifers at Green River, meaning that lithium brines from the deeper clastic zones and Mississippian Units can flow without impacting the shallow aquifers.

Work so far has indicated the lithium-rich brines could flow to the surface naturally, which would then potentially reduce operating costs by eliminating the need for mechanical pumping to extract brines from depth.

Breakthrough at Green River with first carbonate product

ASN has made another breakthrough at Green River after producing its first lithium carbonate product from the SDP.

The lithium carbonate was produced with raw brine from the nearby Paradox Lithium Project, utilising the existing flowsheet to prepare the plant to receive raw brine from the Boysdaba #1 well.

The Boysdaba #1 well is located 200m from the SDP and is nearing the end of its drilling program which will take samples from the Clastic 31 and the Mississippian Unit.

This nearby extraction point will provide ASN with an opportunity to test the flow sheet design with brine correspondent to future production conditions.

Ongoing improvements to the SDP process

The SDP will run continuously for six months, producing battery grade lithium carbonate (Li2CO3). Like a pilot plant, ongoing improvements will be made to the process using feedback provided by the Inductively Coupled Place (ICP) unit installed at the Green River Lithium site.

ASN says this enables adjustment to the process in real time and will accelerate the testing period. Lithium carbonate samples will be provided to potential off-take Original Equipment Manufacturer (OEM) partners, including electric vehicle and lithium-ion battery manufacturers.

This latest test work consisted of both the adsorption and desorption processes applying Anson’s proprietary designed procedures to be used in the production plant facility. The lithium eluate generated is then purified and processed to produce lithium carbonate.

Data to be collected during commissioning of SDP

“The successful commissioning of the Sample Demonstration plant on our own property at Green River will allow us to optimise the Direct Lithium Extraction flow sheet which was developed during the DFS by using brine samples as close as possible to those that will exist in a full-scale production,” ASN executive chairman and CEO Bruce Richardson says.

“This includes temperature, pressure and mineral grades including lithium.

“Data collected will be used to further refine the flow sheet, delivering more accurate recovery rates, rejection rates which will provide further confidence to investors, off-takers, and end-users.

“This is yet another significant step forward in the development of Green River, Anson is fully aware of the national security objective of developing a lithium supply chain in the USA and is working at a rapid pace in Green River to assist in meeting this Federal Government objective.”

This article was developed in collaboration with Anson Resources, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.