Dotz Nano aims to stop flood of fake COVID-19 facemasks

Image: GettyImages

Special Report: Counterfeit PPE is flooding hospitals around the world, but there is a way to stop it. Dotz Nano has a solution and already cut the first deal to start cleaning up the sector.

Millions of counterfeit medical facemasks are popping up in hospitals around the world following the scramble by authorities for personal protective equipment (PPE) in March and April.

Now manufacturers are racing to find ways to prove theirs are the real deal, and have hit on Dotz Nano’s (ASX:DTZ) ValiDotz security markers.

Dotz recently signed a $1.5m deal with Hong Kong-based Universal Exports Group, a corporation specialising in wholesale distribution, to use its security markers on 100 million facemasks destined for government stockpiles and the UK’s National Health Service (NHS).

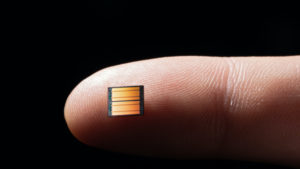

The carbon-based tracing solution contains non-toxic nanoparticles that can ‘tag’ a physical product, solid or liquid, during the manufacturing process.

Dotz’s anticounterfeiting solution for facemasks involves embedding an encrypted and specially marked QR code that the recipient can read using a smartphone application or dedicated reader, to authenticate the mask for its origin throughout the supply chain.

Phase one will see 30 million facemasks embedded with a Dotz security marker, but it isn’t just limited to masks. Universal Exports also has rights in China and South Africa for two years over ValiDotz-marked medical gowns and gloves and PPE as well.

The counterfeiting epidemic

Counterfeit PPE may not sound dangerous, but one facemask is not the same as another, and this puts medical professionals working in COVID-19 wards at risk of infection.

In Australia, the regulator, Therapeutic Goods Administration (TGA), dropped strict rules in March that required all facemasks to be tested before registration, as it sought to make it easier for hospitals to buy PPE on mass.

The result has been a flood of poor-quality masks into Australia that do not have good filters, or ear straps that break or fall off.

That has taken place within a bigger deluge of fake PPE around the world covering everything from fake gowns to COVID-19 test kits and counterfeit hydroxychloroquine.

But this is just the tip of a counterfeiting epidemic that is worth $US1.8 trillion a year, according to Research and Markets, infects 3.3 per cent of global trade, and affects almost every product around the world.

Speaking to Stockhead Dotz CEO Uzi Breier said, “Traditionally, counterfeiting has been confined to popular consumer brands and products. Over the past few years, we’ve seen this spread to high-value goods in many industries including pharmaceutical, automotive and safety products, such as child car seats and now PPE.

“Counterfeiting is putting consumer lives at risk and there’s a real need for manufacturers to adopt and implement solutions that allow consumers to verify if they are purchasing a genuine and qualified product.”

Fighting the good fight

Authenticating products throughout a supply chain is a relatively recent move by companies, under pressure from customers, shareholders and governments which are demanding more ethical sourcing, in particular.

Breier says many anticounterfeiting solutions are relatively easy for forgers to replicate or remove and often can’t be verified on-site by the consumer or end-user.

The company has been commercialising its carbon-based tag, trace and verify solutions since it listed in late 2016 and following a pivot early last year, is diving into the anti-counterfeiting, plastics, and oil and gas sectors with a series of deals.

Dotz’s end-to-end authentication technology is built around the ValiDotz™ security markers and proprietary InSpec™ detectors, which allow for on-site verification of products.

“Dotz’s security markers can be embedded into a range of raw materials, from lubricants through to plastics, during the manufacturing process without affecting the properties or appearance of the tagged product,” Breier says.

“Our security markers are placed onto products using a secret method, are virtually impossible to reverse engineer and can be detected instantly in-line.

“Our end-to-end anticounterfeiting solutions enable product verification throughout the supply chain, and in terms of our recent anticounterfeiting solution for facemasks, by the end-user as well.”

The company has developed a bespoke product for medical facemasks in response to COVID-19 that involves adding a smart marking label with Dotz’s unique security technology, during production.

The label contains an encrypted QR code, featuring a range of information including Unique Identification Number, name of distributor, geographical destination, order number, batch number and date of production.

Extra codes can be embedded into the products for extra security if need be. A smartphone app identifies the information embedded in the QR code.

This story was developed in collaboration with Dotz Nano, a Stockhead advertiser at the time of publishing.

This story does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.