1,000ml: SOR hits ‘critical milestone’ for self-charging battery tech, shares surge to new 2020 high

The company’s Battery Ink technology could be a game-changer in the $U16bn Internet of Things (IoT) market.(Image: Getty)

Special Report: The company’s Battery Ink technology could be a game-changer in the $U16bn Internet of Things (IoT) market.

Tech innovation company Strategic Elements (ASX:SOR) announced a crucial R&D milestone this morning – production scale-up for its market leading Battery Ink technology.

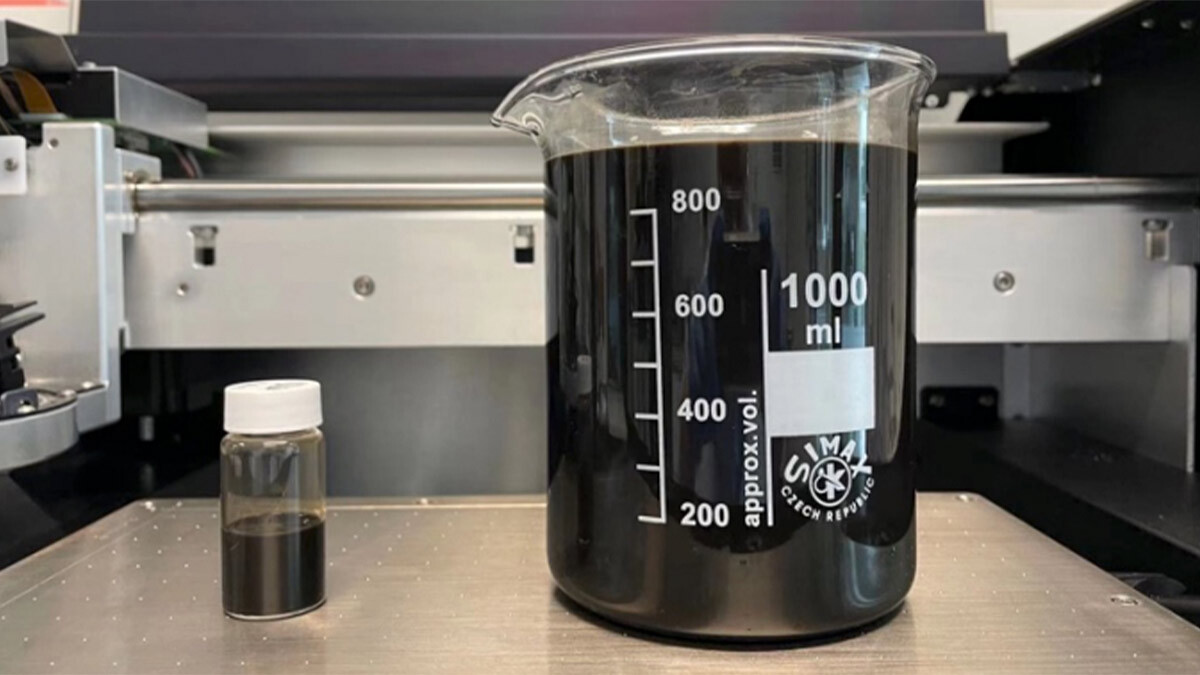

The company said its research team, in conjunction with the University of New South Wales and the CSIRO, has manufactured a 1-litre batch of Battery Ink significantly ahead of schedule.

The 1-litre batch has the capacity to produce 2,000 battery cells. It marks an important research achievement, because it demonstrates proof of the group’s capacity to rapidly ramp up production and achieve economies of scale.

The group’s first batch had the capacity to produce 200 cells. But through the intellectual property developed in that process, the research team was able to expand production “rapidly and very early”, SOR said.

Battery rollout

Shares in SOR ripped higher to new 2020 highs of 19.5c at the opening bell, marking a gain of almost 500 per cent since April.

Having achieved commercial scale for its Battery Ink, the research team is now accelerating plans for a prototype battery pack.

The pack – now due for completion by January 2021 — will utilise multiple connected Battery Ink cells with the capacity to produce 3.7 Volts.

SOR’s Battery Ink cells work by harvesting humidity from the air which they use to self-charge.

From its scaled-up 1-litre Ink batch, the research team was able to fabricate five Battery Ink cells – each of which were 1cm wide and 10-20 microns thick (thinner than human hair).

All five battery cells generated at least 0.8 Volts of energy by harvesting air humidity over a two-hour time period, with a rapid recharge time of less than three minutes.

The team also established proof that there were no issues around the reliability and performance of the battery cells, compared to cells produced from the smaller 200ml Memory Ink batch.

The Battery Ink technology is also being developed with the use of a graphene derivative called graphene oxide, which is cheaper and more widely available than traditional graphene.

The use of graphene oxide as a key input in terms of the Battery Ink’s capacity to scale, because the cost of traditional graphene usually restricts its use to research purposes only.

Billion-dollar opportunity

SOR’s Battery Ink technology has a number of commercial opportunities within the global Internet of Things (IoT) market – including wearable electronic devices.

Manufacturers of wearable devices such as heart rate monitors and calorie counters derived revenues of more than $US10 billion in 2019.

However, most products in the space use lithium batteries which are excessively bulky and still require manual recharging.

Battery Ink cells provide a basis to build products that are thinner, more flexible, and non-flammable with the capacity to recharge within minutes.

And because human skin generates elevated humidity levels (around 90 per cent), SOR’s technology has the capacity for rapid recharge while being worn.

This shows “strong potential for the Battery Ink cells to provide a flexible, light, self-recharging power source for the electronic skin patch sector that is forecast to grow to nearly $US40 billion by 2030”, SOR said.

Along with the January rollout of its self-charging battery pack, “work will also occur concurrently on increasing current output at lower humidity levels”, the company added.

The company’s self-charging battery technology is derived from the intellectual property it has developed in connection with its Nanocube Memory Ink project.

SOR is also moving towards commercial development of its Autonomous Security Vehicle (ASV), a joint project with global engineering giant Honeywell.

This article was developed in collaboration with Strategic Elements, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.