Zeotech can produce synthetic zeolites from mine and process tailings – here’s why that’s a big deal

Pic: John W Banagan / Stone via Getty Images

Zeotech (ASX:ZEO) aims to become Australia’s first manufacturer of synthetic zeolites with its novel and proprietary mineral processing technologies developed by the University of Queensland (UQ).

But what exactly are synthetic zeolites?

They are manufactured aluminosilicate minerals with a sponge-like structure, essentially molecular sieves with tiny pores that make them useful as catalysts or ultrafine filters.

Zeolites act almost like a magnet that can hold heavy metals, ammonia, low level radioactive elements, toxins, petrochemicals, and gases – which presents a commercial environmental management solution.

They are used in:

- Detergent builders;

- PVC heat stabilisers;

- Gas separation (air purification, oxygen production and industrial applications);

- Water treatments (heavy metal removal);

- Moisture removal/drying;

- Insulating glass units; and

- Animal feed supplements (mycotoxin adsorbents).

Zeolites can even be designed to selectively adsorb molecules or ions depending on their unique construction and can be regenerated repeatedly for re-use.

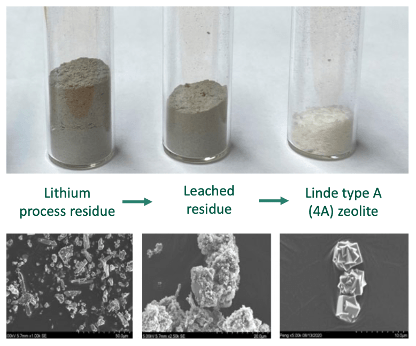

Not to mention that Zeotech (ASX:ZEO) and UQ have already proven they can even produce synthetic zeolite from leached spodumene residue, which is the downstream process tailings waste that is produced by lithium hydroxide refineries.

As lithium battery demand grows its anticipated that the lithium refinery sector will produce significant amounts of leached spodumene residue, so refineries are looking for tailings management solutions.

The opportunities are endless

“The opportunities for the company are incredible, just due to the fact of the versatility of synthetic zeolites,” Zeotech managing director Peter Zardo said.

“The largest volume area for consumption of synthetic zeolites is the powder detergent industry, although by value its molecular sieve zeolites, as they have an incredible range of applications.

They’re primarily used in drying and purification by separating gases, actually they’re really good at separating almost anything.

We even had the Indian High Commission in Australia reach out to us regarding synthetic zeolites used as adsorbents in oxygen concentrator units during the height of the pandemic due to the decreasing supplies of medical grade oxygen, globally.

“When the Chernobyl disaster happened, they actually used synthetic zeolites to attract the radioactive elements to remove them from the surrounding area.”

Zeotech’s proprietary process for the manufacture of synthetic zeolites has a low environmental footprint, which equals a sustainable product. Not to mention the process of creating them presents as a commercial environmental management solution for suitable mine tailings and process residues.

This is because the tailings waste can actually be used as feed for low-cost production of zeolites.

Improved downstream margins for lithium players

Zeotech sees a market opportunity here, and with UQ, has lodged a leached spodumene residue treatment provisional patent application.

The process has potential to improve economic and environmental outcomes for lithium refineries by offering an integrated solution capable of improving downstream margins by consuming leached spodumene residue streams.

Currently, the production of lithium concentrates from spodumene results in the generation of fine leached spodumene ending up in processing residue stream (in some cases up to 70%).

And as lithium battery demand grows, it is anticipated that the lithium refinery sector will produce significant amounts of residue – and that’s where synthetic zeolites could provide the perfect cleantech solution.

“We feel we can be competitive in offering the lithium refinery sector (option) because we’ve been working with major lithium companies since last August, and now we’ve got two refineries providing us with feed for the pilot program,” Zardo said.

The size of different zeolites is a key price factor

Zardo said that while synthetic zeolites are very, very good at what they do, they are quite expensive.

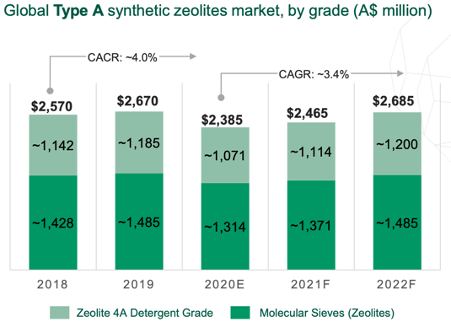

Detergent grade zeolites use low-cost inputs, so the value is lower – between $500-700/tonne.

But the company produces the high-grade zeolite type A which costs between $2,500-4000/tonne and represents around 60-70% of the zeolite market.

Type A applications include:

- 4A – detergent building, PVC heat stabilisers;

- 3A – natural gas drying, refrigerant drying and moisture removal for polyurethane plastic/paint; and

- 5A – separating alkane types, co-adsorption of carbon dioxide and moisture, and pressure swing adsorption (PSA) for gases.

Then there’s type X zeolite which costs more, but Zardo said the market – gas drying/separation/absorption – is not big enough.

“In the molecular sieve market 80% is type A and 20% is type X,” he said.

“If you’re going to do something like take lithium process residue or lithium waste and convert it into a zeolite product, you can’t be converting it into a product that’s only 20% of the market, because you’ve got to have a lot of it.

“So, Zeotech is focused on producing type A because that’s where the volume is and that’s where the margins are too.

Pilot program the next stage

Zardo said within the next few months the company expects to have a continuous circuit up and running, with the aim of starting construction on the pilot plant towards the end of the year.

“We’re thinking of commissioning towards the end of the year, but it could be early next year,” he said.

“The reason why the timing is a bit up in the air is we keep getting additional feed and it’s almost like another pilot program each time that happens.

“But we’re very confident that our pilot program will be finished in the first half of next year and if the pilot plant goes well – which we anticipate it to – we could be designing and starting to build a mini plant for the second half of next year.”

The mini plant could potentially be revenue generating because just last month the company announced plans to acquire the Toondoon Kaolin project in Queensland, and Zeotech already has the Abercorn kaolin asset also in Queensland.

This means the company can use the kaolin to create the synthetic zeolites, as well as feed from existing lithium partnerships.

Zeotech share price today:

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.