Sovereign’s graphite co-product has lowest global warming potential compared to peers

Mining

Mining

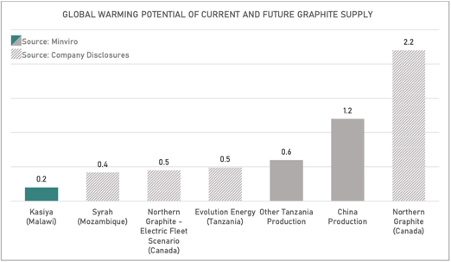

Sovereign Metals says graphite product from its Kasiya project in Malawi could have the lowest global warming potential (GWP) of publicly reported current and future potential graphite production anywhere in the world.

Independent benchmarking covered a cradle-to-gate life cycle assessment (LCA) which indicates the GWP of producing one tonne of flake graphite concentrate at Kasiya to be 0.2 tonnes of CO2 equivalent emissions (CO2e).

That’s significantly lower than natural graphite production from China and proposed near-term production from Tanzania at 1.2 tonnes CO2e and 0.6 tonnes CO2e respectively.

It’s also three times less polluting than the proposed Tanzanian production from hard rock sources and six times less polluting than current Chinese production – which accounts for up to 80% of current global graphite supply.

Despite graphite being only a co-product to future potential rutile production, Kasiya is still one of the largest and potentially lowest production cost flake graphite resources in the world as it is hosted in soft and friable saprolite material instead of hard rock.

“It is remarkable that our graphite co-product from planned rutile production at Kasiya will not only be potentially one of the lowest cost flake graphite projects in the world but now can also be considered to have one of the lowest global warming potentials of current and future graphite mines,” Sovereign Metals (ASX:SVM) MD Dr Julian Stephens said.

“Producers and users of lithium-ion batteries are already taking note of the carbon footprint associated with the raw materials that feed into battery technology – so to be developing Kasiya at this time is truly exciting.”

Notably, Sovereign’s primary product of natural rutile is expected to have a GWP of only 0.1 tonnes CO2e – up to 97% lower than alternative titanium feedstocks produced by upgrading ilmenite.

The lower GWP for Kasiya graphite is achievable because it is hosted in soft, friable saprolite material which will be mined via hydro methods (high pressure water monitors) powered by renewable energy sources including hydro power from the Malawi grid and on-site solar power.

This is opposed to the production in Heilongjiang Province, China where hard-rock ore requires drilling, blasting, excavation, trucking, crushing, and grinding – which are overall high CO2e activities.

Plus, the project’s low carbon footprint will set it apart in the lithium-ion battery supply chain, which is the main emerging market for flake graphite.

Greater capacity batteries, such as those required for electric vehicles, are expected to drive significant demand for graphite over the coming years, with the sector expected to become the largest graphite market segment by 2028.

It is forecast the battery sector will become the largest graphite market segment by 2028.

This article was developed in collaboration with Sovereign Metals (ASX:SVM), a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.