Richard Poole’s REZ confirms nickel sulphide discovery at Springfield

Pic: Getty

Further investigation of recent drill results from the Springfield prospect has confirmed that REZ has indeed uncovered the nickel sulphide holy grail at a project that has up until just recently only been looked at for its vast gold potential.

Sydney-based, ASX-listed Resources & Energy Group (ASX:REZ) has confirmed that seven of the samples taken from two holes recently drilled at Springfield, part of the East Menzies project in Western Australia, contain magmatic nickel-iron sulphides.

Richard Poole says nickel sulphide is a game changing discovery for REZ

“The confirmation of magmatic nickel-iron sulphide mineralisation is a significant and material exploration result for the Springfield project, and the East Menzies package in general,” Executive Director Richard Poole said.

“It allows for the possibility that the ultramafics and nearby lithologies may host larger accumulations of disseminated and massive nickel-iron sulphides.”

REZ made the Indiana Jones-style discovery in September last year while it was looking for more gold at East Menzies. Drilling returned a peak assay of 1m at 1.78% nickel from 98m.

The Richard Poole-led company has now confirmed the discovery following an analysis of the mineralogy, geochemistry, and textural attributes of samples taken from three drill holes.

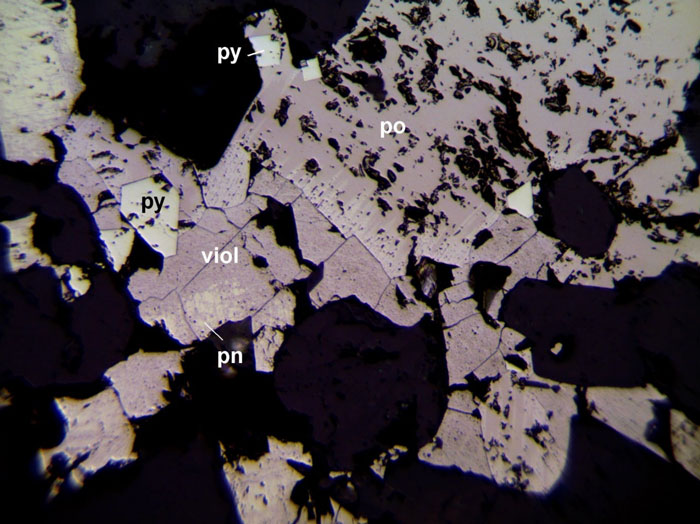

This analysis identified the key nickel-iron sulphide bearing minerals pentlandite, violarite, smythite and gersdorffite.

Pentlandite is a nickel-iron sulphide mineral and a principal source of nickel, while violarite and smythite are supergene nickel and iron sulphide minerals associated with the partial weathering and oxidation of primary pentlandite and other nickel sulphide minerals. Gersdorffite is a nickel arsenic sulphide mineral.

comprised pentlandite (pn) extensively replaced by supergene violarite (viol),

intergrown with pyrrhotite (po) and pyrite (py).

REZ initially realised Springfield also played host to nickel after it got its hands on some old CRA (now Rio Tinto) and BHP reports that showed the two mining heavyweights had found nickel as far back as the late 60s but weren’t interested in it because they only wanted gold.

BHP back in 1986 reported significantly high values of nickel, with a peak grade of 2.9%, and as close to surface as just 6m.

This was at the Cepline prospect in the Springfield Venn zone, some 800m north of the REZ’s recent scout drilling program.

The documented occurrences of sulphides at Cepline, were also considered to be prospective features for the occurrence of magmatic nickel sulphides, volcanic exhalative nickel sulphides and base metals deposits.

REZ is targeting these occurrences rather than the shallow near-surface lateritic nickel deposits, which have been the subject of previous investigation at East Menzies and elsewhere in the broader Menzies region.

“Nickel resources are usually divided between laterite or sulphide deposits.” Executive Director, Richard Poole.

Sulphides are the holy grail for explorers because they are easier and cheaper to process. This is also what makes nickel sulphides the preferred choice of electric vehicle battery makers.

What is Nickel Sulphide?

Nickel sulphide is a critical component of batteries and is the preferred chemical feed for lithium-ion batteries. Hybrid electric vehicles have long used nickel-bearing LiBs, and the shift to full battery electric vehicles is expected to follow. However, LiBs with iron will remain in use, and may not be replaced in the near future. Hence, it is crucial to increase production of LiBs in the coming years.

To make lithium-ion batteries, nickel sulfide powder is produced from laterite ore. This powder is used as a crucial ingredient in lithium-ion batteries. It is also used in producing stainless steel and other alloys. It is a valuable resource in the lithium-ion batteries industry. It is also used for making battery-grade sulfate. This is a highly efficient way to generate electricity.

The demand for nickel sulphate will also rise due to the increasing demand for EV batteries. The production of EVs will double by 2025, and the demand for nickel sulphate will increase from 33 Kt in 2017 to 570 Kt in 2025. The demand for high-purity class 1 nickel will grow from the plating to foundry sector to 570 Kt in 2025.

Nickel Sulphide is confined to commercial applications. Its green coloured solution is an inorganic compound that is highly soluble in aqueous solutions. Normally, the mineral morenosite is found in nature, but its production can be easily controlled by dissolving it in sulphuric acid. This chemical is produced as a concentrated solution and used for a variety of industrial applications. It is toxic and can cause cancer when exposed to fumes, so it should be handled carefully.

Treasure trove of green metals in Australia

The same drilling that unearthed nickel sulphides also showed significant intervals of mineralisation that included cobalt, chromium, molybdenum, zinc, platinum and palladium.

This article was developed in collaboration with Resources & Energy Group, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.