Protean Energy is just days away from starting its Korean vanadium resource estimation

Pic: John W Banagan / Stone via Getty Images

Protean Energy — a vertically integrated vanadium resource and battery developer — says it is starting mineral resource estimation at its flagship Korean vanadium deposit within days.

Completion of Stage 1 portable X-Ray Fluorescence (pXRF) testing of existing drill cores will enable an interim mineral resource estimation over about 40 per cent of the known 8.3km strike length.

The project, called “Daejon”, is unique as a sediment hosted shale/slate bed vanadium deposit which has the potential to produce high purity vanadium pentoxide.

The exploration target is between 70-90Mt at 0.25-0.35 per cent vanadium pentoxide. There is also a significant uranium credit associated with the deposit.

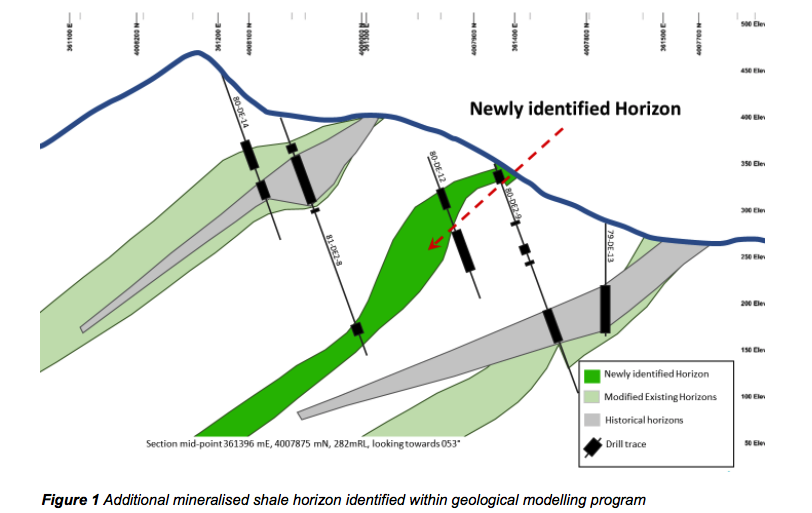

Protean (ASX:POW) has completed a geological modelling program which has added a third black shale zone to the existing two. It’s expected to host additional vanadium mineralisation.

Black shale rock is so-called because it includes large amounts of organic matter.

The interim resource estimate is expected to be finalised by July.

After the Stage 1 p-XRF data is collected, Protean plans to start on Stage 2 test work targeting the remainder of the 8.3km of mineralised strike.

- Bookmark this link for small cap breaking news

- Discuss small cap news in our Facebook group

- Follow us on Facebook or Twitter

- Subscribe to our daily newsletter

Protean Energy is advancing its vanadium project in South Korea and aims to eventually supply the Korean market.

South Korea is one of the largest steel producers globally. The country is also looking to establish itself as a major player in the Vanadium Redox Battery space, with heavyweights Samsung and LG looking to break into the market.

Vanadium batteries can store more power and last much longer than other battery-types such as lithium-ion.

Battery maker

Protean is also in the battery building business. With vanadium prices up 175 per cent over the last 12 months, having an in-house supply is useful.

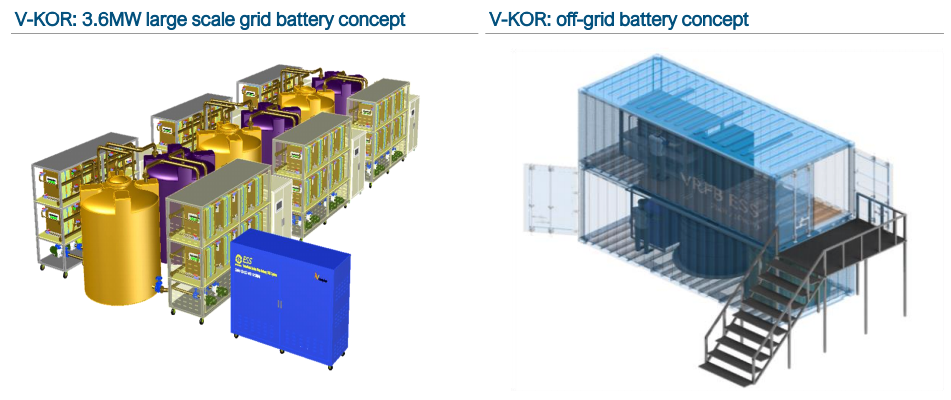

Via a 50 per cent owned Korean affiliate KORID Energy, Protean is building and testing its V-KOR range of vanadium redox flow batteries in Australia.

It will soon start trialing a 25kW/100kWh vanadium V-KOR battery in Western Australia.

The test battery is now being shipped to Australia. Installation is expected to start in May.

Vanadium redox flow batteries are made up of two tanks of vanadium pentoxide (V₂O₅) that have been processed into a liquid solution called an electrolyte.

When the electrolyte is pumped through electro-chemical cells past a proton-exchange membrane, ions are swapped between the negatively and positively charged electrolyte, creating a charge.

V-KOR has been developed over the past five years and patents have been granted to protect the design.

To date, four stack sizes of batteries have been developed including a 2.5kW, 5kW, 10kW and 25kW, and the technology is expected to drive the adoption of clean energy solutions.

This special report is brought to you by Protean Energy.

This advice has been prepared without taking into account your objectives, financial situation or needs. You should, therefore, consider the appropriateness of the advice, in light of your own objectives, financial situation or needs, before acting on the advice.

If this advice relates to the acquisition, or possible acquisition, of a particular financial product, the recipient should obtain a disclosure document, a Product Disclosure Statement or an offer document (PDS) relating to the product and consider the PDS before making any decision about whether to acquire the product.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.