MTM’s Flash Joule tech testing delivers game changing gallium and germanium recoveries

MTM Critical Metals’ Flash Joule Heating tech has achieved ~90% gallium and ~80% germanium recoveries. Pic: Getty Images

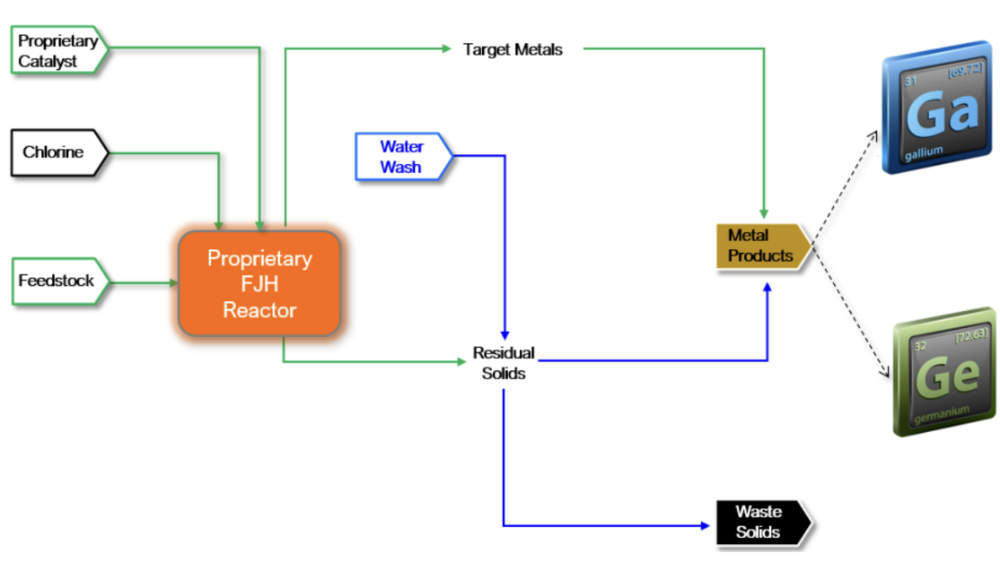

- MTM’s Flash Joule Heating tech achieves ~90% gallium and ~80% germanium recoveries from high-value scrap

- Results match or exceed traditional methods despite FJH being simpler and faster without the use of acid

- Company now optimising process to improve purity and improve recovery yields

Special Report: MTM is a step closer to helping the US reshore critical minerals production after initial testing of its Flash Joule Heating technology on waste material returned excellent gallium and germanium recoveries.

Initial testing of the advanced electrothermal process on semiconductor metal refining waste achieved recoveries of ~90% gallium and ~80% germanium.

These recovery rates match or exceed traditional methods and were achieved using a far simpler, more sustainable and streamlined process that doesn’t use acid and has faster processing speed.

With the US keen to reshore critical minerals production and inter-linked Chinese export restrictions, the prospect of deploying a cost-effective domestic method of gallium and germanium recovery from waste – a first of its kind process – places MTM Critical Metals (ASX:MTM) on the leading edge of solving this supply chain vulnerability.

“We’re thrilled with FJH technology’s versatility across multiple metals, and the latest test results for ultra-high-value technology metals couldn’t be timelier given the current geopolitical landscape,” MTM managing director Michael Walshe said.

“Gallium and germanium are indispensable to semiconductors and defence applications, yet their supply chains remain highly vulnerable due to overwhelming dependence on imports—particularly from China.

“MTM’s proprietary process offers a commercially viable, environmentally friendly solution to secure domestic supplies of these strategic materials, creating a major economic opportunity for the company.”

Strategic partner Indium Corporation, which provided the waste material for testing, was also pleased with the result. Its business unit manager, metals Markus Roas said the test results were “meaningful and could be an industry game-changer” for recycling critical technology metals.

“The ability to recover gallium and germanium from waste streams represents an important opportunity to establish a circular supply chain for materials that are essential to semiconductors, defence, and renewable energy industries,” Roas added.

Critical metals

Gallium, germanium and indium are classified as critical minerals by the US Department of Defense due to their use in high-tech industries including the manufacturing of semiconductors.

Of these, there is no primary domestic production of gallium or indium while over 50% of germanium is met through imports.

Prices for both gallium and germanium soared across 2023 and 2024 after China – the world’s largest producer – placed export restrictions on a range of critical metals.

This scenario makes the ability to recycle critical metals in a cost-effective manner – such as with the company’s FJH tech – a key link in securing supply chains.

MTM is progressing development of a FJH demonstration plant capable of producing 1t per day of critical metals such as gallium each day from high-value scrap material containing up to 20% indium, 15% gallium and 18% germanium sourced from Indium under their strategic partnership.

It noted at the end of January that process and mechanical design was on track for completion by the end of February and that it had already shortlisted several areas and initiatives to secure an existing industrial site to expedite timelines.

The company also noted that start-up of the inaugural plant remains on track for Q4 2025.

Looking ahead, MTM’s next phase of testing will focus on optimising reaction conditions to further purify gallium and germanium products, improving recovery yields and expanding trials to other critical metal-containing feedstocks.

Discussions are also ongoing with industry partners regarding commercial business models for maximising critical metal recoveries and optimising value for large-scale application of this technology.

This article was developed in collaboration with MTM Critical Metals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.