Magnetite Mines firms up Razorback’s potential for higher grade, lower cost iron ore

Pic: Bloomberg Creative / Bloomberg Creative Photos via Getty Images

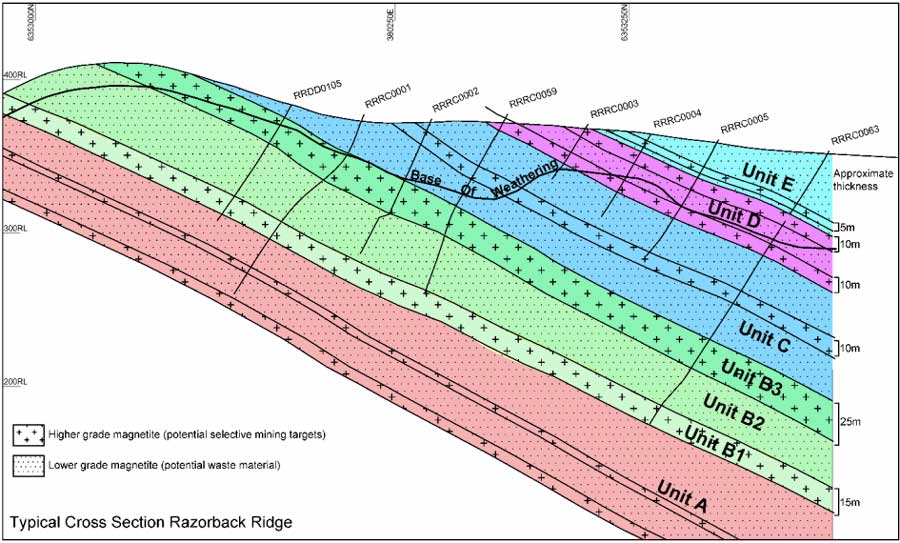

Special Report: Studies have shown that selective mining of Magnetite Mines’ 4-billion-tonne Razorback iron ore mine in South Australia could significantly boost the economics of the project.

Initial studies have confirmed the lateral continuity of high-grade iron ore horizons within the existing resource are potentially amenable to selective mining, a method used successfully by major iron ore miners like Fortescue Metals Group (ASX:FMG).

When combined with complementary ore sorting, selective mining these higher-grade horizons could deliver higher-grade ore to the processing plant.

Higher plant head grades would result in higher tonnages of ore produced compared to an equivalent conventional bulk mining and processing scenario with potential advantages in operating and capital cost efficiency.

“What this will do, if we can put it all together and make it work which we obviously think we can, it’s got the potential to significantly increase the head grade,” Magnetite Mines director Mark Eames told Stockhead.

“It may be a gamechanger for us, it’s a potential step change in the economics.”

Eames said selective mining would significantly reduce water and electricity costs for the project.

“Water is one of our big constraints because we’re using groundwater, so it’s much more efficient in terms of water use, it’s much more efficient in terms of electricity use and it has the potential to substantially reduce that cost,” he explained.

“We’ve already got very promising results from the scoping study with the bulk mining last year. This selective mining opportunity will further enhance the economics and make the project much more efficient and potentially, over time, much larger.”

Extensive mineralised zones

Kerry Whitby, the managing director of McElroy Bryan Geological Services (MBGS) – the company undertaking the technical studies, said while the study was still to be completed, the lateral continuity of mineralised horizons traced throughout the deposit so far was substantial.

mining targets. Pic: Supplied.

“The vision of Magnetite Mines to approve downhole geophysical logging of all their exploration holes has led to a consistent and valuable data set that not only identifies the discrete magnetite-rich bands within the sequence but also makes possible the potential to selectively mine those layers,” he explained.

“The unusual combination of relatively soft outcropping ore and continuous bands of magnetite mineralisation may be unique to Razorback and the Braemar Iron Formation and as a result, MBGS is now progressing with 3D grid geological modelling of the Razorback deposit with a view to supporting the assessment of a selective approach to mining.”

Razorback is what Magnetite Mines dubs a “globally unique opportunity” and that’s because it has the potential to produce the highest grade of any iron ore operation in Australia as well as globally.

Lab tests undertaken by the company have already demonstrated it can produce grades of nearly 70 per cent.

It has all the right ingredients to make it a lower cost development project than other mines. The resource is at surface, so stripping ratios are low.

The rocks at Razorback are also much softer than other iron ore projects, particularly in Western Australia, and require less energy to grind, which lowers the cost.

Executive Chairman Peter Schubert said the potential continuity of high-grade zones in the extensive Razorback resource was an important technical opportunity for Magnetite Mines.

“We are encouraged with the results so far of the selective mining PFS work that our expert advisors are undertaking,” he said.

“These indications have parallels with the ‘lateral macroband continuity’ presented by Fortescue Metals Group in 2008. These findings may result in a pathway to materially shift the key development parameters of the Razorback project.

“We look forward to keeping shareholders informed as we progress this exciting technical work that is advancing our fundamental understanding of our orebody.”

Magnetite becoming the iron ore of choice

Magnetite Mines is well positioned to take advantage of rising iron ore demand and the surging price, given processed magnetite ore is becoming the product of choice for Chinese steelmakers.

There are two main types of iron ores – hematite and magnetite. Haematite is higher grade in the ground, while magnetite deposits are large and quite low grade – but produce very high-grade products.

With the depleting direct shipping ore — the stuff that you can just dig up and ship — in WA’s Pilbara, end users like steelmakers in China are increasingly demanding more processed ores like magnetite.

About a third of the world’s steel is made from processed or magnetite-rich ores and globally there’s a bunch of big successful mines that have been producing for years.

Next steps

Eames said test work is currently underway to investigate how the geophysical signatures correlate with the iron ore grade and mass recoveries.

“This is the first step in potentially a technical journey that’ll take some time, but it’s really highly significant,” Eames said.

“We’re still looking at doing an ore sorting trial as well which will further improve the efficiency of the project.”

A detailed resource model for use in mining and pit optimisation studies, which is intended to incorporate the new information about the higher-grade zones, is also being undertaken.

This article was developed in collaboration with Magnetite Mines, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.