Lithium Australia subsidiary VSPC boosts products mix with LTO battery anode powders, shares climb

Energy

Energy

Lithium Australia NL’s (ASX:LIT) fully-owned subsidiary ,VSPC Ltd, is getting into the lithium titanium oxide (LTO) game.

The company announced today that it has added commercial quality LTO anode powder to its product mix.

LTO anode power is an important material in the manufacturing of high performance lithium-ion batteries (LIB) cells.

In addition to lithium ferro phosphate (LFP) and lithium manganese ferro phosphate (LFMP) cathode powders — which VSPC’s plant is already producing — the company announced today that its manufacturing capability now includes LTO, with the performance of its LTO exceeding industry benchmarks.

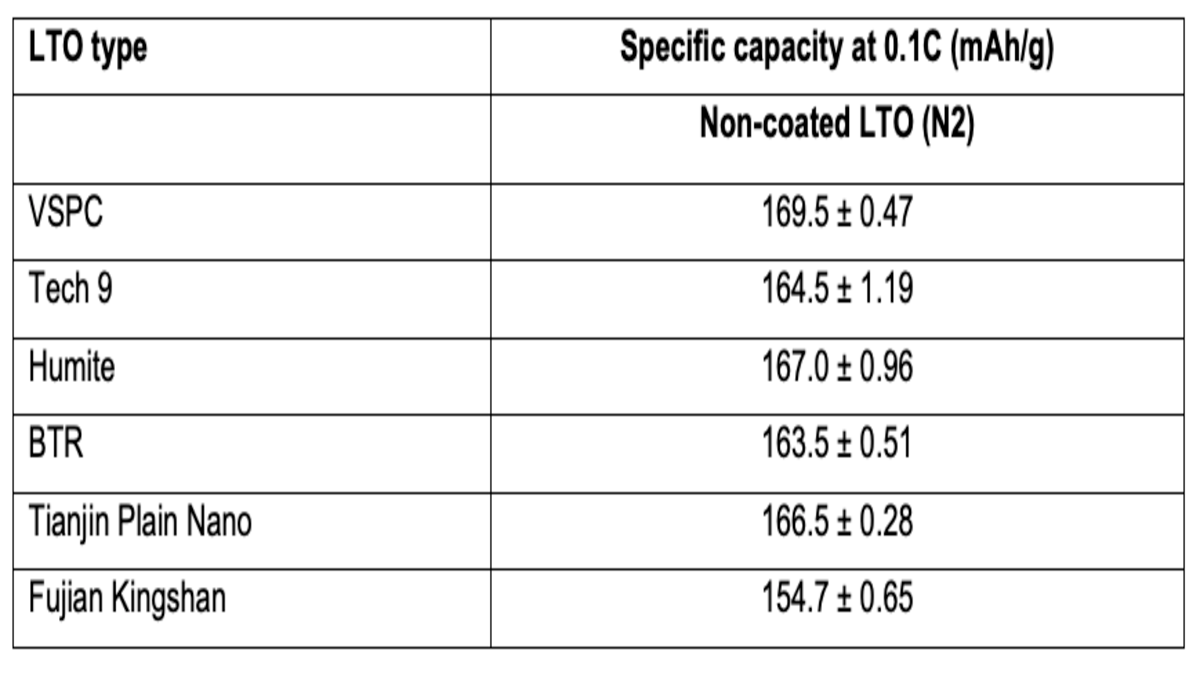

When VSPC’s LTO was benchmarked against five commercial LTO products, the material achieved a specific capacity of 169 milliampere hours per gram at 0.1C, Lithium Australia said.

Overall, VSPC’s LTO achieved “superior specific quality” when compared with other commercially available materials, including Tech9 LTO and Hombitec LTO.

LIT shares jumped 8.7% on the news to 12.5 cents.

Conventionally, LTO is prepared through a solid-state reaction, with titanium dioxide (rutile or anatase) and lithium carbonate or lithium hydroxide as the raw materials.

VSPC said these materials are calcined at temperatures above 800° Celsius for a prolonged period (between 12 to 24 hours) to ensure a high-phase purity and because its patented, slurry-based process reduces calcination time and ensures consistent phase and end-product quality, it is ideal for producing LTO.

As well as creating new market opportunities, VSPC’s success with LTO has prompted the company to expand its research into other anode battery materials, including titanium niobium oxide and other niobium-based anode materials often used in space and defense applications.

VSPC is now developing an anode materials work program with other organisations that are leading research in this area.

Blackstone Minerals (ASX:BSX) has engaged engineering consultants Wood and leader in metallurgical testing ALS to carry out critical roles in the delivery of the definitive feasibility study (DFS) at the Ta Khoa Refinery in Vietnam.

Wood, recognised in the industry as a leading hydrometallurgical group, will be responsible for providing project management, project controls, engineering, cost estimating and execution planning services for the TKR plant design.

ALS on the other hand, will conduct a peer review on the TKR PFS process flow sheet, including bench scale confirmatory test work to confirm operating parameters ahead of piloting.

A pre-feasibility study for the development of the refinery project was released back in July, demonstrating that the plant could process up to 400ktpa (base case) of nickel concentrate to produce battery grade NCM811 precursor for the lithium-ion battery industry.

A final investment decision is earmarked for the project in 2022 following the DFS and pilot plant testing.