Li-S Energy CEO Dr Lee Finniear on the disruptive battery tech allowing EVs to drive further, for longer

Pic: Justin Paget / DigitalVision via Getty Images

Battery tech company Li-S Energy (ASX:LIS) listed on the ASX this week after raising $34 million via an IPO of 40 million shares at $0.85. It jumped a whopping 221% on day one, with shares trading at $2.70 before setting down to a solid $2.08 today.

So, what’s all the fuss about?

Stockhead asked CEO Dr Lee Finniear, who said it all comes down to its unique tech which extends the life cycle of lithium-sulphur batteries to create a genuine alternative to lithium-ion.

Boron nitride nanotubes extend the battery life

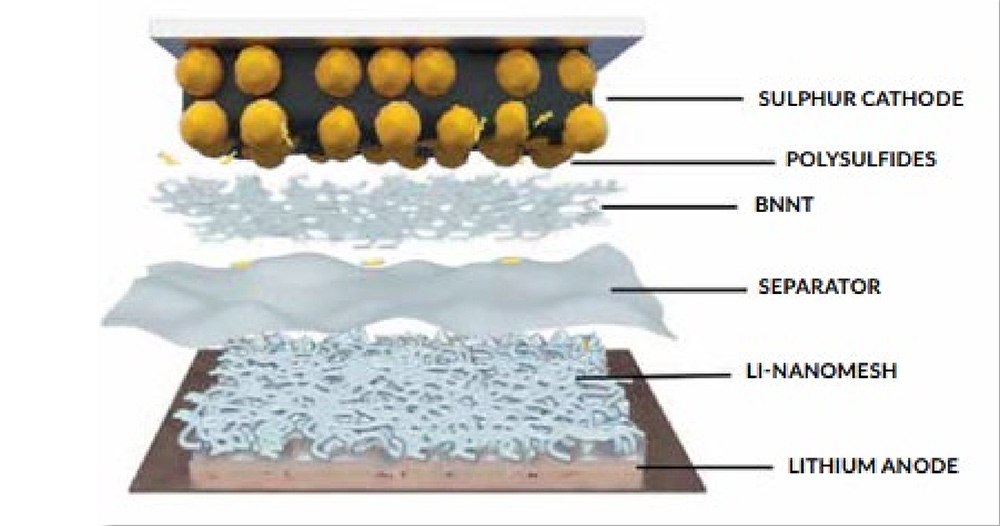

“With a lithium sulphur battery, we’ve got a lithium metal anode and a sulphur carbon cathode that has a theoretical energy density of around five times that of a lithium-ion battery,” Dr Finniear said.

To put this in perspective, lithium-ion batteries are currently getting up to around 270–280-watt hours per kilogram, compared to lithium-sulphur batteries at around 450-watt hours per kilogram.

This means Li-S technology could substantially extend battery life, allowing EVs to drive further, drones to fly longer and mobile devices to last for days instead of hours.

The key is using boron nitride nanotubes (BNNTs) to mitigate the polysulphide shuttle effect.

Basically, the batteries are normally so energetic that they fail after around 55 charge/discharge cycles.

This is because when the lithium sulphur battery discharges, its sulphur forms lithium polysulphides – some of which are soluble.

These soluble polysulphides can come out of the cathode onto the anode, meaning active sulphur is lost and the capacity of the battery is reduced over time.

But by using BNNTs in the construction of the cathode it stops the polysulphides moving while still allowing the lithium ions – which are a lot smaller – to move.

“BNNTs are really unique material, they’re over 100 times stronger than steel, they’re an electrical insulator, which is good, but they’re also highly conductive,” Dr Finniear said.

“It acts a bit like reinforcing bars in concrete to help strengthen the cathode to reduce mechanical degradation.”

Fixing the dendrite problem with nanomesh

“When lithium-ion batteries were first invented they had a lithium metal anode, but they had a lot of dendrite problems,” Dr Finniear said.

“Dendrites are kind of like spikes that grow out of the lithium as it charges and discharges.

“We’ve developed a new composite nanomaterial called Li-Nanomesh which smooths the flow of lithium ions back onto the lithium anode.

“Without that, what happens is the lithium ions tend to be attracted to high spots on the anode – very much like a lightning conductor on the roof of the building attracts all the lightning – and dendrites grow.

“This nanomesh actually spreads the flow of the ions out across the surface of the lithium.”

Dr Finniear said that in tests on cells without the nanomesh, dendrites have formed and the battery has failed within about 45 cycles.

“But with the nanomesh on, we’ve gone over 1000 cycles with no hint of dendrites – so it’s very exciting,” he said.

Commercialisation plan is to license IP

Dr Finniear said the next step for the company is rigorously testing the technology with the end goal to licence the IP to battery makers.

“Battery manufacturers have incredible skills for high volume, low cost manufacturing, they invested billions of dollars into factories and have thousands of people that know how to manufacture batteries at scale,” he said.

“We’re not that kind of company and we don’t want to compete with those organisations, we want to partner with them.

“We think that’s the fastest route to market.

“And we have also cornered the market in terms of the Li-Nanomesh as well as the BNNts because we have an exclusive distribution agreement from BNNT Technology Limited that allows us to sell BNNTs on to anyone in the battery industry making lithium sulphur batteries.

“So, we’ll make will make money out of the nanomaterial sales as well as the licensing and royalties.”

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.