Landfill methane is a big, hard-to-abate contributor to emissions. This company might have a solution

Methane from landfills are a significant contributor to greenhouse gas emissions. Zeotech’s zeolite products might hold the key to abating them. Pic: via Getty Images.

- Landfill methane makes up ~30% of Australia’s methane emissions, which are a significant part of its overall greenhouse gas emissions

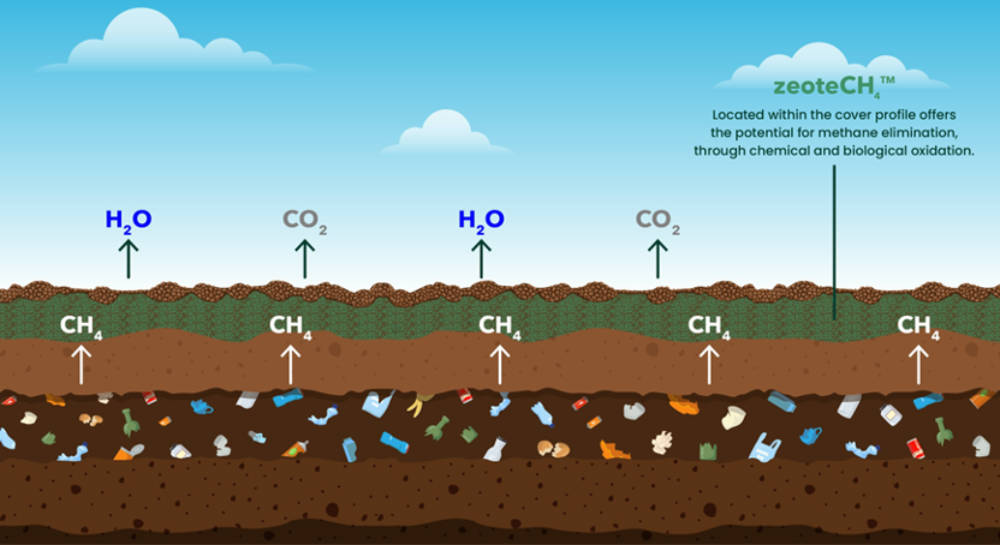

- Zeotech’s zeolite technology aims to achieve 70-80% methane oxidation when combined with methane oxidising bacteria

- On track to advance to infield trials at a Cleanaway landfill facility at the conclusion of the current research activities expected by early Q1 2024

- Application of ZeoteCH₄ products to mining and agriculture being evaluated

As Australia continues to press towards achieving net zero emissions by 2050, every little bit of action taken to reduce emissions from a wide range of sources will contribute to this goal.

Much of the attention is centred on reducing carbon dioxide (CO2) emissions and that is perfectly fine given that it makes up the bulk of all greenhouse gases released each year.

However, less is done to reduce the amount of methane that’s released into the atmosphere.

While far less methane is emitted by our activities, it is more than 28 times more potent as CO2 at trapping heat in the atmosphere and accounts for about 16% of global emissions according to the US Environmental Protection Agency.

As such, being able to reduce the amount of methane emitted will go a long way towards reducing our overall emissions.

Australia has clearly recognised this with Climate Change and Energy Minister Chris Bowen making a non-binding pledge in October this year to reduce our methane emissions by 30% by 2030.

This can be a tricky preposition as one of the most significant sources of methane is landfill, which at least one source indicates is responsible for some 30% of all Australian methane emissions.

Landfills are – by their nature – spread out over a large area, making it challenging to capture the methane they produce.

Challenge accepted

However, emerging mineral processing technology company Zeotech (ASX:ZEO) may have the answer to mitigate methane emissions from landfills.

The company specialises in producing zeolites – commonly known as molecular sieves – using its novel and proprietary mineral processing technology.

Zeolites are porous mineral frameworks, naturally occurring or manufactured, composed mainly of aluminium, silicon, and oxygen.

Their three-dimensional structures can trap, exchange, or release ions and molecules, enabling zeolites to find applications in diverse industrial and environmental contexts.

Trials carried out in conjunction with Griffith University into the use of zeolites in a layer capping landfills to control emissions has now borne fruit with batch experiments displaying early methane oxidation efficiency of up to 70-80%.

Importantly, the methane oxidising bacteria are actively colonising and co-existing with the company’s products with results to date showing promise for standalone chemical oxidation at ambient temperature and pressure, which is contributing toward the overall effectiveness of ZEO’s zeoteCH₄ product as a practical methane abatement technology.

“We are very encouraged by the early methane oxidation efficiencies observed to date, not only through primary pathway of biological oxidation, but the additional process of chemical oxidation that is facilitated by Zeotech’s zeolite-based materials,” Griffith University school of environment and science, Australian Rivers Institute senior lecturer Dr Chris Pratt said.

“We remain excited to be working on such a valuable project which could potentially contribute to Australia’s pledge to reduce methane emissions by 30 per cent by 2030.”

Zeotech chief executive officer Scott Burkhart added that the promising early methane oxidation outcomes exceeded the company’s expectations and provided confidence the zeoteCH₄ products could offer a compelling fugitive methane control solution.

“The program continues to build important datasets and know-how, with novel aspects being developed which could further enhance the company’s intellectual property suite,” he said.

Landfill research

Zeotech’s research program began at Griffith in February 2023, aimed at developing zeolite-based technology deployed within the surface capping soil of landfills to adsorb and eliminate methane emissions through chemical or biological oxidation (or a combination of the two).

Early research activity focussed on collecting and evaluating the properties of the landfill capping soils gathered from the host site operated by industry partner, Cleanaway Waste Management.

Analysis of the chemical methane and carbon dioxide adsorption capacities of the company’s targeted zeoteCH₄ products have been completed and efficient methane adsorption properties have been observed, which demonstrates that Zeotech’s targeted products meet the first criteria for effective methane elimination.

Importantly, bench-scale tests have shown that the presence of zeoteCH₄ materials does not inhibit microbial growth, and that the microbes are actively colonising and co-existing with the zeoteCH₄ products.

This is important as the primary mechanism for methane abatement is expected to be from a process of biological oxidation – with the bacteria actually ‘consuming’ the methane and converting it into hydrogen and carbon dioxide.

Of the four methanotroph (methane-consuming bacteria) sources, two have displayed high maximum oxidation rates and have been selected as the preferred candidates to inoculate the zeoteCH₄ materials and advance biological oxidation experiments.

As previously noted, early batch experiments have displayed promising oxidation efficiencies of 70-80% for two of tested zeoteCH₄ compounds, complementing the bench-scale tests.

More work to follow

Zeotech and Griffith University will now focus on approaches for inoculating the zeolite materials with methanotroph bacteria to optimise and maximise methane oxidation potential, together with adapting experiments under conditions that are closely aligned with anticipated field environment.

The company noted that while 70-80% methane oxidation rates are highly encouraging, the process is still underway and the best performing zeoteCH₄ compounds that could advance to field validation are yet to be determined.

As such further activities will be reserved until the conclusion of the current activities and provision of the associated progress report, which is expected by early Q1 2024.

Additionally, Zeotech will evaluate the potential to apply zeoteCH₄ products more broadly as a methane abatement solution across other large industries including mining and agriculture.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.