Former SpaceX engineers raise $US50m to build automated electric rail cars

Pic: Getty

Parallel Systems has “come out of stealth mode” after raising $49.55 million in Series A funds to build autonomous battery-electric rail vehicles that move freight.

The round was led by Anthos Capital, and includes investments from deep tech funds Congruent Ventures, Riot Ventures, Embark Ventures, and others.

Parallel was founded by three engineers who formerly worked at Elon Musk’s cutting-edge space transportation company, SpaceX.

Parallel CEO Matt Soule was previously SpaceX head of avionics for 13 years, where he led a department of 300 people in the design and testing of space electronics.

John Howard, vice president of Hardware, introduced lithium-ion to human spaceflight as head of batteries at SpaceX. Ben Stabler, vice president of Software, was head of avionics software and lead engineer for motorised actuator electronics at SpaceX over five years.

Soule says the company’s competitive edge is “autonomous battery-electric rail vehicles, which are designed to move freight cleaner, faster, safer and more cost effectively than traditional trains or trucks”.

How does it work?

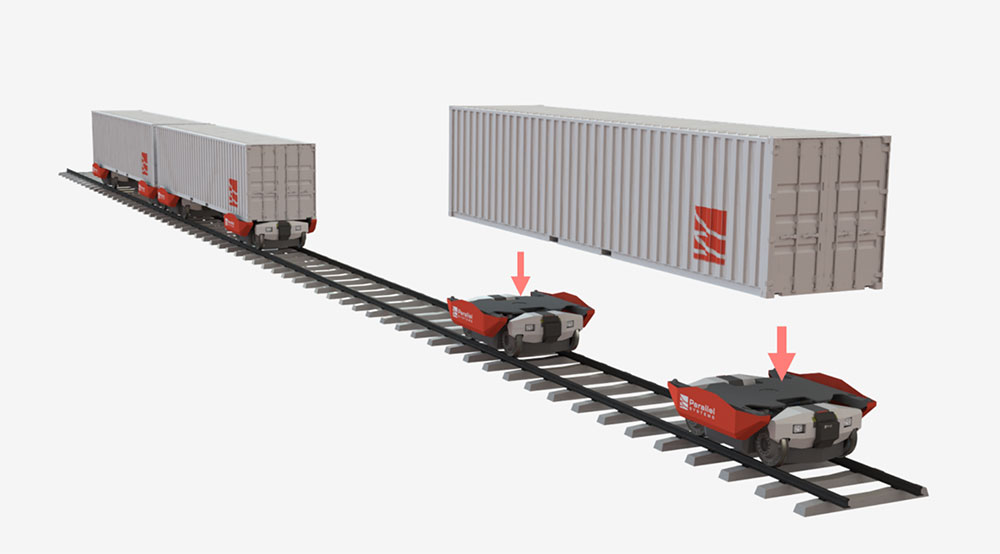

The company’s autonomous battery-electric rail vehicles load and transport standard shipping containers as a single or double stacked load.

The railcars, which are individually powered, can join to form ‘platoons’ or split off to multiple destinations while en-route.

That makes them a lot more flexible than traditional trains.

“Unlike traditional freight trains, Parallel’s platoons do not need to accumulate large quantities of freight to make service economical, which enables more responsive service and a wider range of routes,” the company says.

“This dramatically reduces the waiting times associated with loading trains that are miles long. The system can support service at a range of distances, from across a city to across the country.”

These cars have a range of between 800 and 1280 kilometres – using 25% of the energy of a semi-truck – with a payload capacity up to 5.8 tonnes each.

Charging time is less than an hour, Parallel says.

Alleviating the shipping crisis

To make freight deliveries economical, today’s railroads typically focus on moving shipping containers distances more than 800km, Parallel says.

Much of the remainder is done by trucks, but a shortage of truck drivers is currently squeezing supply chains globally.

Parallel’s flexible rail system could alleviate pressure on the trucking industry as it faces overwhelming demand and a driver shortage of 80,000 drivers in the US alone.

“Our business model is to give railroads the tools to convert some of the $700 billion US trucking industry to rail,” Soule says.

“Today, trucks are responsible for moving most of the nation’s freight by miles.

“Moving a portion of that freight volume to autonomous battery-electric rail will help alleviate highway congestion, improve road safety, reduce road wear and tear, provide shippers with more cost-effective transportation, and provide environmental health and safety benefits by reducing GHG trucking emissions.”

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.