Altech makes excellent progress on its prototype 60kWh salt batteries for grid energy storage

Altech is rocketing towards having its prototype 60kWh batteries ready for testing and qualification by customers. Pic via Getty Images

- Manufacturing progressing well for Altech Batteries 60kWh CERENERGY® battery prototypes

- More than half the solid state sodium chloride battery cells have been completed

- Low reject and defect rates experienced with prototypes to be finalised in mid-2024

Special Report: Altech Batteries has made excellent progress with the manufacturing of two 60kWh CERENERGY® battery prototypes that will be used for conducting performance tests and qualifying them for customer use.

The unique CERENERGY® solid-state batteries are ideally suited for grid energy storage use and require just common table salt (sodium chloride) and nickel with no need for lithium, cobalt, graphite and copper, limiting exposure to critical metal price rises and supply chain concerns.

Altech Batteries’ (ASX:ATC) solid-state batteries are capable of operating at a very wide temperature range (-40 degrees Celsius to +60 degrees Celsius), are fire and explosion-proof, and have a life span of more than 15 years.

Over their life, they are estimated to reduce costs by up to 40% compared to regular lithium-ion batteries and boast an emissions footprint at least 50% lower than that of lithium-ion batteries.

Battery packs with capacities of 5kWh and 10kWh have already been developed and the company is in a joint venture with German government owned Fraunhofer IKTS to commercialise a 120MWh battery plant on Altech’s land in Schwarze Pumpe, in the German state of Saxony.

Larger capacity batteries progressing well

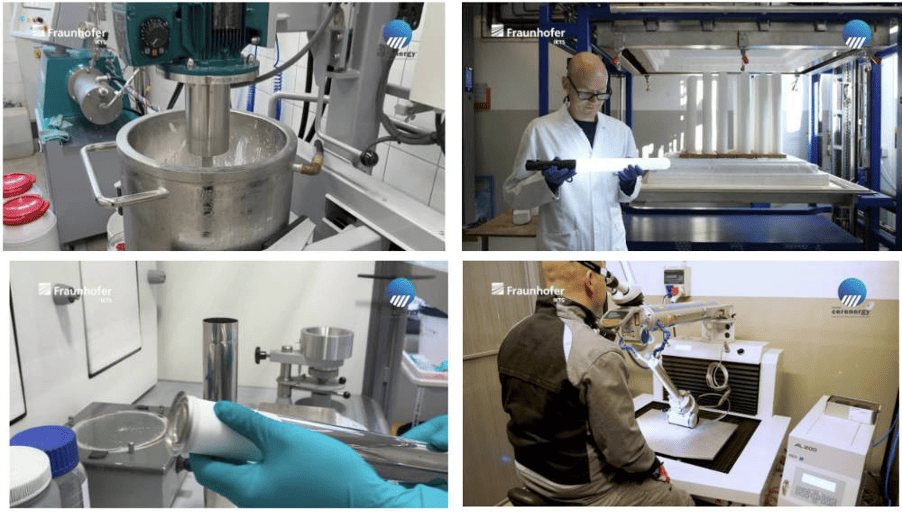

ATC has made excellent progress with manufacturing of the larger capacity 60kWh battery pack prototypes with the pilot line at Fraunhofer IKTS’ facility in Hermsdorf having undergone a comprehensive redesign.

Innovative tools and machinery have been developed and implemented specifically for producing the battery cells required for the prototypes, which comprise 240 CERENERGY® cells, each rated at 2.5V.

All prototype materials have been procured from suppliers while ceramic tube manufacture is now 50% complete.

Cell assembly is also progressing well with more than half completed while experiencing low reject and defect rates, a sign that the company has a good handle on the manufacturing process.

Two battery vacuum casings have been delivered and are undergoing heat loss testing with ATC expecting the prototypes to be finalised in mid-2024.

Once the prototypes are completed, Altech will provide access to select potential customers to demonstrate the practical applications and benefits of the ABS60 series in various industries, whilst also securing offtake agreements.

Successful construction of the ABS60 prototypes will also take the Company’s proposed 1MWh GridPack, which consists of up to 18 of the 60kWh battery packs connected to a power pack management system, closer to reality.

This article was developed in collaboration with Altech Batteries, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.