3D printing innovator AML3D is winning big as the US Navy chases its military edge

AML3D could benefit from the US Navy’s desire to increase its capability. Picture Getty.

- The US Navy is expanding rapidly on the back of geopolitical challenges

- One ASX tech company, AML3D, could benefit from this

- We speak to AML3D’s CEO, Sean Ebert

New geopolitical challenges, along with the Biden office’s prioritisation of modernising the US military, have driven robust demand in 2023 for defence-related stocks.

Analysts believe this demand will continue into 2024 and beyond as geopolitical instability grows.

Unlike many other developed countries, spending on national defence in the US tends to gain support from the masses, as it is considered patriotic.

The Biden government, for its part, is capitalising on this support by making bigger investments to preserve the nation’s military edge.

Underpinning these investments is the Administration’s focus on additive manufacturing technology as a solution to rebuilding the US’s sovereign manufacturing capability.

Called the Biden AM (Additive Manufacturing) Forward Program, the initiative is a voluntary pact among large manufacturers to help their smaller US-based suppliers increase the use of additive manufacturing, otherwise known as 3D printing.

Surprisingly, there is one ASX-listed tech company that has reaped benefits from this program.

The company is a $20m market-capped stock called AML3D (ASX:AL3), a provider of on-demand additive manufacturing services that have gained a foothold within the wider US Navy’s supply chain.

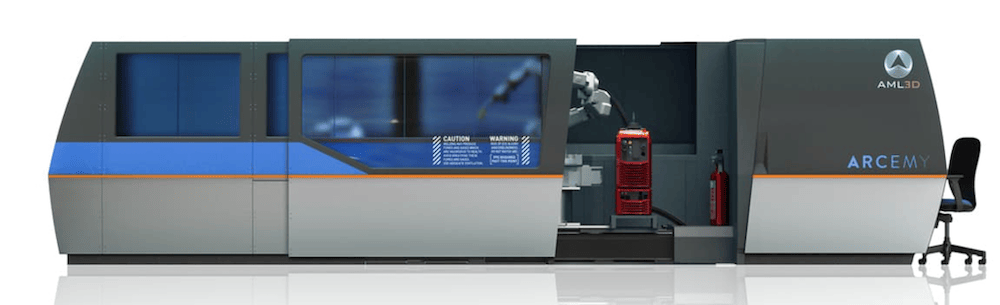

AML3D, which stands for Additive Manufacturing 3D, was founded in 2014 and is the OEM (original equipment manufacturer) of the ARCEMY industrial metal 3D printing system.

“We print large scale, 3D metal parts, and what makes it different for us is that we have a range of alloys that we can print in,” says AML3D CEO, Sean Ebert.

“The core differentiation for us is we’re about 75% faster than casting, and 95% less waste than billet machining. And the parts we produce are typically 30% stronger than cast products.”

US scale up strategy

Shares in AML3D have been rallying in recent months after a series of contract wins in the US.

In late September, the company received its inaugural order for its ARCEMY 3D printing system from the US Navy submarine component partner, Laser Welding Solutions.

While the order was insignificant, it proved to be the stepping stone for a much bigger order worth $2.5 million from a US Defence contractor, Cogitic Corporation, in early November.

This was followed up by another order worth $2.2m to provide a custom built ARCEMY system to be installed at Austal’s (ASX:ASB) USA Advanced Technologies facility in Charlottsville, Virginia.

Whilst details of the contract are obviously sensitive in nature, Ebert said Austal had asked AML3D to make the largest printing system that it could produce.

“So we’ve produced and designed and customised a system for Austal, which essentially has a build volume of about 35 cubic meters,” said Ebert.

“But what’s really important is that the market for us in the US has really taken off, specifically with the Department of Defence’s US Navy.”

“This is all part of our US scale up strategy, which is focused on developing and deepening our long-term, strategic partnership with key stakeholders within the US market.”

The ARCEMY system

Ebert explained that the US Navy Supply Chain Management has chosen and decided to adopt ARCEMY to manufacture parts for the US Navy.

The ARCEMY 3D printing system is basically a medium to large scale metal 3D printer.

It uses the company’s patented Wire Additive Manufacturing (WAM) process, which combines state-of-the-art welding science, robotics, and materials engineering. This allows the 3D printer to produce parts smartly by depositing molten wire layer by layer, in a controlled manner.

“How WAM works is we take metallurgical science, robotics and software technology, and we combine them together to form the WAM process,” explained Ebert.

“What that means is we create a beam of molten metal, and then we sequentially lay that on top of each other to form the geometry of the path that we want to produce.”

“Defence is obviously our major market at the moment, but we’re also working in aerospace, as well as in the oil & gas industry,” said Ebert.

“We’re also doing qualification of alloys, as well as qualification of parts, together with selling systems to their downstream manufacturers.

“So we’ve got multiple, diversified, revenue streams coming out of the US at the moment, and we’re seeing growth in each of those three areas.”

Australian Navy and giant oil companies

Back home, AML3D announced last week that it signed a prototype part manufacture and testing contract with BAE Systems Maritime Australia.

The prototype part has applications within BAE Systems Maritime Australia’s contract to design and build the Hunter class frigates for the Royal Australian Navy.

The contract follows the completion of previous feasibility and test work with BAE to demonstrate that the WAM technology is suitable for Australian marine defence applications.

The contract demonstrates AML3D’s progress in diversifying its revenue base by accessing additional marine and defence sectors.

In addition to defence sector, AML3D has also previously produced a number of parts for the oil and gas customers, Exxon and Chevron.

“We’ve got a couple of parts that we’re making for Chevron at the moment. One has been tested in the US, and the other one is being printed here in Adelaide,” said Ebert.

Sheer growth

While declining to give forecasts, Ebert said the company has a very close relationship with its customers, and most of them have a very long-term investment program.

“So they don’t enter into these contracts lightly, and they’ve given us a fairly good, strong view of what the outlook looks like for them,” said Ebert.

“And that view has become a key platform for us to make that next step, and the confidence to move into the US and set up a facility there.”

“So we’re very, very encouraged, and I’m very bullish on the outlook for the company,” Elbert said, adding that there’s a huge amount of value yet for investors to see in the company.

“We’ve literally signed $11.5 million of orders in the last 10 months. And that’s incredible growth compared to where we were 12 months ago, where we had revenues of $600k.

“So I think just that sheer growth of the company, the inertia of the demand that we’ve seen in particular in the US, should encourage investors to look at our company.”

AML3D share price today:

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.