Viridis metallurgical tests deliver world-leading recoveries of magnet REEs at Colossus

World-leading recoveries of magnet REEs have been reported from VMM’s Colossus project. Pic: Getty Images

- Metallurgical testing for VMM’s Colossus project returns world-leading recoveries of 76% NdPr and 65% DyTb

- Exceptional recoveries achieved using just a fifth of the leaching reagents, which can lower both Capex and Opex

- ANSTO will continue to determine optimal conditions for key processing aspects of the flowsheet

Special Report: Metallurgical testing conducted by ANSTO for Viridis Mining & Minerals using a bulk composite sourced from the Colossus project in Brazil has returned world-leading recoveries of valuable magnet REEs.

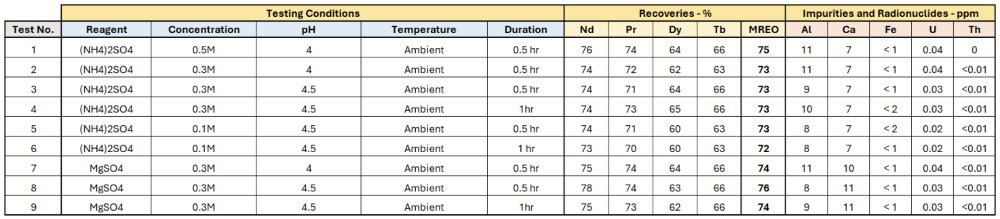

The standard ammonia sulphate (AMSUL) test at 0.5M, pH4, room temperature and a 30 minute leach cycle on the composite sample with a head grade of 4472ppm total rare earth oxides (with 32% magnet REOs) returned strong recoveries of magnet REEs, including 76% for neodymium and praseodymium, and 65% for dysprosium and terbium.

These are believed to represent the highest recoveries worldwide for this kind of testing.

While this is hugely positive for Viridis Mining & Minerals’ (ASX:VMM) and its Colossus ionic adsorption clay-hosted project, which has a significant resource of 201Mt at 2590ppm TREO that is rich in valuable magnet REEs, the real prize might be the further sensitivity cases carried out on the bulk sample.

This work has demonstrated that exceptional recoveries can be achieved at lower molar concentrations, higher pH and shorter residence times, all of which could reduce both the capital and operating costs of the project and provide great optionality on reagent selection.

Notable examples include:

- AMSUL, pH4.5, 30 minutes, 0.3M: Recovery NdPr = 73%, Dy+Tb = 64%

- AMSUL, pH4.5, 30 minutes, 0.1M: Recovery NdPr = 73%, DyTb = 60%; and

- Magnesium sulphate (MAGSUL), pH4.5, 30 minutes, 0.3M: Recovery NdPr = 77%, DyTb = 64%.

This is notable as it implies that Colossus material can consume just a fifth of the usual AMSUL reagents – using the lower 0.1 molar concentration – at a high pH level and still achieve overall MREO recoveries that are just 2% lower than with a standard test, which provides material operational savings while maintaining nearly identical production output.

That overall recoveries improve at a higher pH level of 4.5 also translates into a quicker and cheaper precipitation process from leached slurry into a pure and high basket value mixed rare earths concentrate.

IAC deposits are already known for their potential to deliver low-cost, high-margin operations despite their lower grades compared to their hard rock counterparts, thanks to their shallow, free digging nature and relative ease of processing. This means the metallurgical results are hugely encouraging to say the least.

Exceeds expectations

VMM CEO Rafael Moreno said the results represented an outstanding start to this critical work program for Colossus.

“The metallurgical recoveries have exceeded our expectations and to have such high recoveries across all testing conditions, highlights the robustness of the front end of the flowsheet design which is paramount for quality control of our final product,” he noted.

“The excellent recoveries of the magnetic rare earths, at lower molar concentrations and higher pH’s, will go a long way in reducing the operating costs and bodes well for the project economics. These are significant breakthroughs which will greatly assist in providing a lower CAPEX and OPEX operation.

“The higher pH conditions have also resulted in even lower levels of radionuclides and gangue elements in the leached solution. This helps reduce the complexity and quantity of reagents required in the downstream processing facilities.

“I’m looking forward to completing the remainder of the test program, which will support the finalisation of the flowsheet design and the associated CAPEX and OPEX estimates in the scoping study.”

Future work

VMM notes that ANSTO will continue to determine optimal conditions for key processing aspects of the flowsheet.

In parallel, infill drilling at Cupim South Extensions remains on track and will support an updated resource estimate in Q4 2024.

The company is also looking to complete its scoping study in the coming months and will continue its permitting activities.

This article was developed in collaboration with Viridis Mining & Minerals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.