Viridis inks game changing deal to refine all 17 rare earths from Colossus

Under the JV, IXR’s IonicTech refining capabilities can potentially add enormous value to production from Colossus. Pic via Getty Images.

- Selective separation tech (SST) can refine all 17 REEs from deposits

- The 50:50 JV with Ionic (ASX:IXR) allows Viridis to implement SST at its Colossus project

- The deal is part of the company’s ‘mine-to-magnet’ strategy

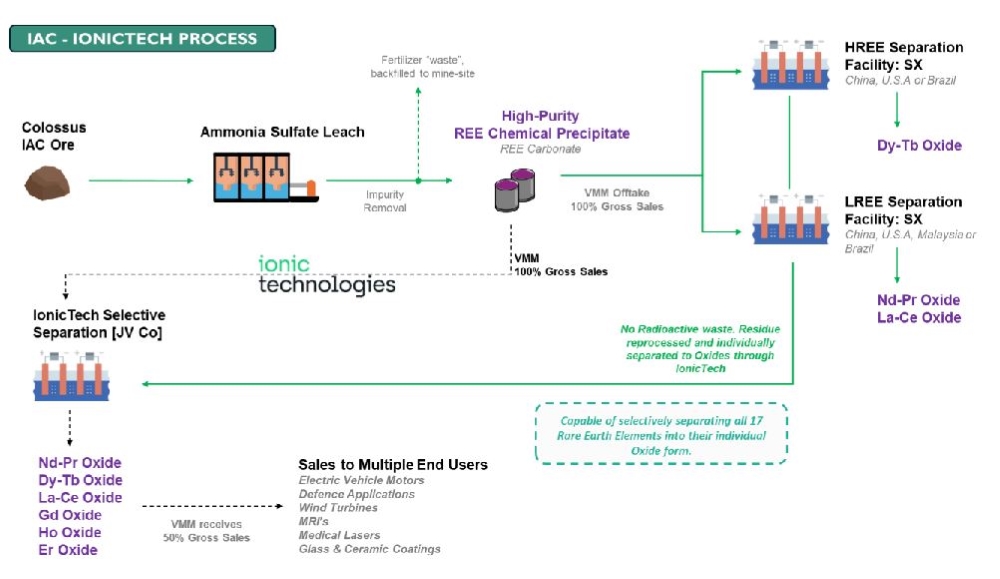

Special Report: Viridis Mining & Minerals is positioning its Colossus ionic adsorption clay-hosted (IAC) rare earths project in Brazil to be the first producer of all 17 refined rare earth oxides through a 50:50 JV with Ionic Rare Earths.

Viridis Mining & Minerals (ASX:VMM) rerated heavily after acquiring Colossus in August last year and has since expanded the initial 91km2 landholding in Poços de Caldas, Brazil, up to a dominant 239km2.

Colossus is potentially a major high-grade IAC deposit, with recent drilling intercepting 6m @ 3,285ppm total rare earth oxides (TREO) including 27% magnetic rare earths (MREO) and 24m @ 4,573ppm TREO (38% MREO).

IAC deposits are known to be low-cost, high-margin deposits that contain valuable magnetic REEs such as neodymium and praseodymium (NdPr) and dysprosium and terbium (DyTb).

VMM has now inked a deal with Ionic Rare Earths (ASX:IXR) for its subsidiary IonicTech’s innovative REE recycling (RRT) and selective separation (SST) technologies and the JV presents a unique opportunity for VMM to introduce this into Brazil.

Traditional REE separation issues

Currently, downstream flowsheets and refineries are limited to separating just a small set of REE oxides – usually just four of them.

One example is Lynas Rare Earths’ (ASX:LYC) integrated refinery in Malaysia, capable of taking REE-carbonate feed from its Mt Weld project in WA to produce separated NdPr and lanthanum-cerium (LaCe) oxides.

To extract more REEs, LYC is constructing a separate US$258m refinery in Texas to take that same feed to produce the heavy rare earth oxides.

The same goes for MP Materials’ Mountain Pass plant in California which is only capable of producing NdPr and LaCe oxides, whether the carbonate feed has concentrations of heavy rare earths or not.

Yet with IXR’s RRT and SST IP, Viridis will be able to capture value from all 17 REEs in a single integrated circuit within a downstream plant in Brazil.

Selective separation a game changer

SST acts like a ‘drop in’ solution using IXR’s separation technology which can be retrofitted into an existing plant and allow for a mixed rare earth carbonate (MREC) feed to extract the full suite of rare earths – rather than being limited to just a single pair.

Combining this with IXR’s commercially ready recycling tech, miners will be able to extrapolate more value from carbonate production from a single plant, saving hundreds of millions of dollars in additional plant construction costs.

Conceptual flowsheet for Colossus integrating IonicTech into its downstream plant. Pic supplied: (VMM)

Mine to magnet supply chain

The JV entails the construction of a refinery facility and implementing IXR’s extraction technology to sell REE carbonates from Colossus, with the JV company able to provide that tech to projects around the world.

VMM CEO Rafael Moreno says the JV now places Viridis at the forefront of rare earth companies outside of China.

“We are looking to capitalise on our first mover advantage with this mature downstream technology and support the current discussions being held with the burgeoning supply chain that’s developing in Brazil,” Moreno says.

“This is evident with the recent announcements made by Toyota, Volkswagen, Stellantis, Hyundai, BYD and General Motors.

“It also provides Viridis an accelerated and de-risked pathway to generating significant IP around the scaling of selective separation technology for mixed REE carbonates and concentrates, which can be licensed/commercialised for other REE projects globally.

“The JV also aims to be the first company to bring commercially ready REE recycling into Brazil (on an exclusive basis), using a technology which has been developed following years of R&D at “IonicTech’s Belfast facility, with the goal of enabling Brazil to become a major player in the downstream supply of REOs.

“Once scaled up successfully, this technology has the potential to capture the full value from a projects REE basket, providing enormous value for Colossus and many other REE projects.

“With this JV, Viridis is continuing to work towards the development of a globally significant IAC project, whilst also sitting at the forefront of REE separation and recycling technology in Brazil.

“We are excited to leverage the incredible geology present in Brazil alongside our strategic partnership with Ionic Rare Earths to create a circular mine-to-magnet supply chain.”

This article was developed in collaboration with Viridis Mining & Minerals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.