Vertex Minerals reaches 60pc throughput at Reward gold plant

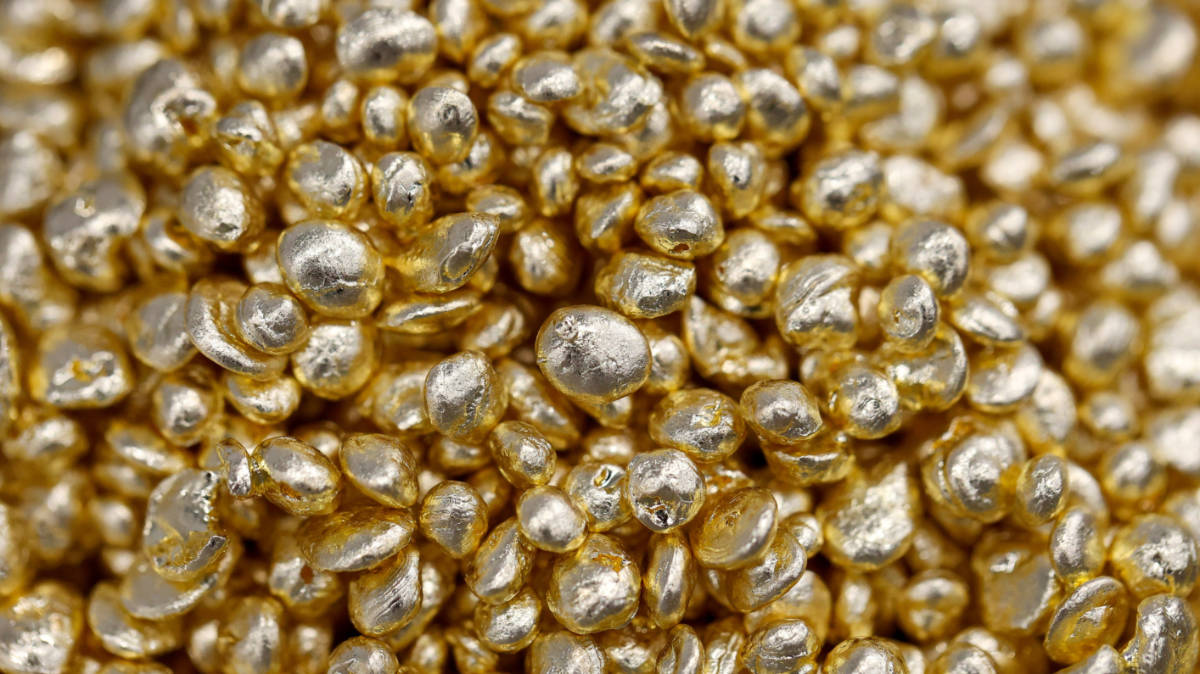

Plant commissioning at Vertex Minerals’ Reward gold mine is ongoing with modifications to suit future Reward underground ore feed. Pic: Getty Images

- Vertex Minerals’ process plant achieves 60% throughput rate of nameplate capacity during commissioning

- The company’s main game is mining the Reward high-grade gold material

- The arrival of a TD1 jumbo rig is expected on site during the next six weeks

Special report: Vertex Minerals is tuning its processing plant to cater for a wider range of feedstock at its Reward Gold mine in the NSW goldfields.

The company says it is gaining confidence in the processing and gold grade in the surface stockpiles, given they are adjacent to the plant offering an inexpensive feed source during the commissioning process.

Modifications to the plant include a reduction in clearance within the jaw crushers, dampeners over the sorting screen, increasing the gold concentrate resident time in the Falcon concentrator, increasing the recycling load in the regrind mill and adjusting water flows for different circuits.

During the next six weeks, Vertex Minerals (ASX:VMS) plans to integrate further modifications and improvements by incorporating a pre-screening scalper to reduce fines in the crushing system and pre-screening oversize fines material to the re-grind mill prior to the Falcon concentrator.

Commissioning of the plant using the existing low-grade surface stockpiles has enabled modest first concentrate production, allowing Vertex the opportunity to optimise gold collection processes.

A small sample of gold has been sent for refining and sale to test the process while a larger size gold concentrate batch is building as throughput increases.

It will be dispatched for refining and sale when worthwhile volumes are obtained.

Aiming for higher efficiencies

VTX executive chairman Roger Jackson said the processing of the surface stockpile material presented some real challenges with the way the old stockpile material breaks down causing frequent piping blockages.

“These blockages have hindered the plant availability and throughput, however, the processing team has worked diligently to overcome a vast number of issues in a short period of time,” he said.

“Our technical team and operators have been implementing low-cost components and strategies to minimise the fine material into the process.

“Whilst this has set us back in time with moving to cash flow, it is important to note that our main game is mining the Reward high-grade gold mine material.

“Delays due to plant tuning today should translate to higher efficiencies earlier in the mine plan.

“Meanwhile, our underground team has been busy preparing the historical workings in anticipation of the arrival of our TD1 jumbo drill rig with dewatering, ground support and re-entry tasks underway.”

Shift towards underground mining

The TD1 jumbo – due to arrive on site from Kalgoorlie in six weeks – is a crucial piece of equipment that will herald the start of a new era of mining at the historical Reward gold mine at Hill End.

VTX said it was a key milestone in the development of the project, signalling a significant shift towards underground mining, and subsequently, underground ore feed into the process plant.

Management continues to source other capital items required to furnish and operate the Reward mine.

Additional ground support will be installed when the TD1 jumbo drill rig has arrived and has been commissioned on site.

Listen: Roger Jackson on the Explorers Podcast

Click below to tune in to Roger Jackson’s episode on the Stockhead Explorers Podcast with Barry FitzGerald

This article was developed in collaboration with Vertex Minerals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.