This Must Be The Placer: Why Ark Mines’ Sandy Mitchell will be home to attractive rare earths products

A new report suggests Ark Mines will have a low cost pathway to dig up rare earths from its Sandy Mitchell deposit in Queensland. Pic: Getty Images

- An independent metallurgical review shines light on low-cost development options for Ark Mines’ placer-style Sandy Mitchell rare earths deposit

- Located in far north Queensland, the deposit should be amenable to low-cost processing methods like gravity and has already demonstrated its capacity to deliver a high-grade rare earth concentrate

- Concentrate is likely suited to third party processing by leading producers in China and the West, including Lynas Rare Earths

Special Report: A new report suggests Ark Mines’ Sandy Mitchell rare earths project in far north Queensland boasts all the hallmarks of a low-cost, easily accessible rare earths deposit ahead of the tabling of its maiden resource.

Commissioned by Ark Mines (ASX:AHK), the expert consulting report on the mineralogy of the Sandy Mitchell deposit has concluded it will be ‘highly amenable’ to simple low cost beneficiation such as gravity processing.

The consulting report by Queensland advisory firm Harrier Project Management utilised analysis from Met-Chem Consulting to compare the placer style of mineralogy found at Sandy Mitchell to other forms mined globally.

The results are enlightening.

According to the USGS, Placer deposits are a shallow style of mineralisation where grains of a valuable mineral like gold or rare earths are mixed with sand deposited by a river or glacier.

Unlike deeper hard rock deposits or ionic clays, they tend to require simpler processing methods because they are easy to handle and don’t require large amounts of energy or clean water to liberate the minerals of value from the mullock.

The analysis showed Sandy Mitchell would likely be able to produce a rare earth concentrate with simple, low cost beneficiation processes like gravity, which are far cheaper to construct than the whole-ore flotation methods required for hard rock deposits – the kind of rare earth projects typically mined in the West.

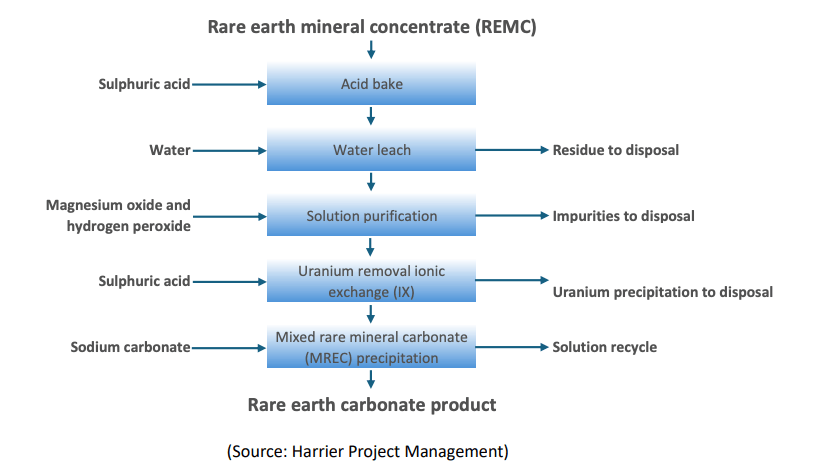

And with beneficiation test work already completed at Sandy Mitchell that delivered concentrates with grades of up to 51.9% total rare earth oxide, it is expected to be suited for refining by standard sulphuric acid baking refiners.

Those include Lynas Rare Earths (ASX:LYC), which has plants using that method in Malaysia and Kalgoorlie, as well as in China at projects like Bayan Obo.

On the right track

AHK Exec director Ben Emery said the results of the independent metallurgical review showed Ark was moving in the right direction in its development strategy.

“In particular, the report highlights that, based on assay results to-date, the rare earth mineral concentrate from Sandy Mitchell is highly likely to be accepted by third-party refiners using the sulphuric acid baking process, which is the most widely used process globally for treating the monazite concentrates typically found in placer deposits,” Emery said.

“The report reaffirms our view that Ark is on the right track to develop Sandy Mitchell with a focus on low-cost downstream processing and a low environmental impact. The Company is now focused on a busy period of near-term news flow, commencing with a maiden Mineral Resource estimate which will be based on the Phase 1 drill programme.

“An updated MRE will then be announced incorporating all assay results from the Phase 2 drill program once they are received.

“Concurrently, metallurgical test work will remain ongoing to further refine our understanding of the nature of the deposit and assess the most beneficial downstream processing options. Further test work will support a planned prefeasibility study for Sandy Mitchell in the second half of 2024.”

Placer deposits typically generate high-grade rare earth concentrates in excess of 50% TREO, normally containing monazite as its main host mineral. That is a flagship source of light magnet metals like praseodymium and neodymium.

But they also sometimes contain xenotime, a mineral associated with heavy rare earths like terbium and dysprosium. These magnet metals are rarely produced outside of China and carry prices running at several multiples of NdPr.

A report by consultants Mineral Technologies showed Sandy Mitchell contains largely monazite with small amounts of xenotime, in line with studies undertaken by Japan’s JOGMEC on the deposit in 2010.

Multiple options to develop Sandy Mitchell

While Sandy Mitchell’s likely concentrate product appears attractive for refiners like Lynas and Chinese processors, Harrier has noted the market is about to get a whole lot more competitive for third party feed.

Along with Lynas’ new Kalgoorlie plant, processing plants are under construction in Saskatchewan in Canada and Utah in the USA, while Lynas will also construct new light and heavy rare earth plants in Texas.

“The Harrier report added that processing options for Sandy Mitchell allow for flexibility and staged development,” AHK noted.

“Acid baking and caustic conversion are deemed suitable if the REMC composition is, as currently expected, of a high monazite content.“However, if after further samples and analysis, the xenotime content is found to be high enough, then acid baking would be the preferred option in order to optimise high value terbium (Tb) and dysprosium (Dy) extraction.”

This article was developed in collaboration with Ark Mines, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.