Testwork proves Lithium Energy’s Burke project can produce battery anode material

Lithium Energy’s Burke project can produce spherical graphite suitable for use in battery anode materials. Pic: via Getty Images.

- Lithium Energy’s test work produces high quality spherical graphite using flake graphite concentrate from the Burke project

- Key design criteria metrics developed to support the BAM component of the Burke pre-feasibility study

- Demand for graphite expected to grow as China moves to restrict exports

- Further testing to be carried out along with planning for pilot plant

Special Report: Spheronising and purification test work confirm that Lithium Energy’s Burke project can provide exceptional feedstock to the battery anode materials market.

This is timed to perfection given the Chinese government’s recent announcement that it will place restrictions on graphite exports, potentially increasing the intrinsic value of all non-Chinese deposits.

Burke is 125km north of Cloncurry, next to Novonix’s Mt Dromedary graphite project, and around 783km from the port and future battery materials hub of Townsville, where the Queensland government wants to develop the Lansdown Eco-Industrial Precinct to produce downstream ingredients for battery tech.

The project currently has a resource of 9.1Mt grading 14.4% total graphitic carbon for 1.3Mt of contained graphite.

Metallurgical test work carried out by Lithium Energy (ASX:LEL) resulted in the production of graphite flake concentrate with 95% TGC, setting the stage for the next stage in the purified spherical graphite (PSG) development test work program.

Test work ‘surpasses expectations’

The test work carried out on the graphite flake concentrate in Germany resulted in the production of PSG with >99.97% TGC using potentially low-cost, environmentally safer, non-hydrofluoric acid processes.

Adding interest, the process produced two industry standard sized spherical graphite materials from one graphite flake stream, introducing wider scope for product marketing.

The process also achieved 63% overall graphite recovery in the spheronising process.

LEL has developed the key design criteria metrics to support the battery anode market (BAM) component of the Burke pre-feasibility study.

“The exceptional results of the BAM testwork conducted on the 95% TGC Burke graphite concentrate have surpassed expectations,” executive chairman William Johnson said.

“The development of a flowsheet that supports a two-product strategy, along with the exceptional purity of the final spherical purified graphite of 99.99% TGC, underpins the quality of the Burke graphite and supports the vertically integrated BAM strategy Lithium Energy is implementing.”

Graphite demand accelerating

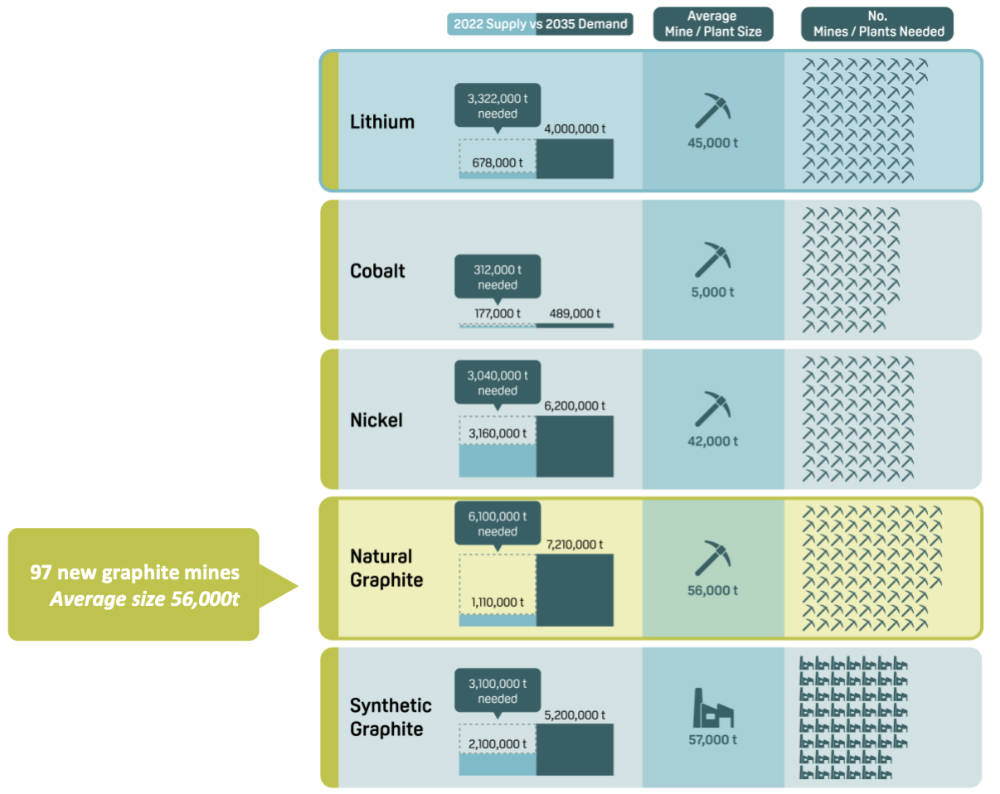

Benchmark Minerals has forecast that 97 new graphite mines with production of at least 57,000tpa of graphite concentrate will be required by 2035 to meet lithium-ion battery demand.

China’s move to potentially restrict graphite exports will only serve to fuel demand for graphite, which makes up a big part of lithium-ion batteries.

“We anticipate that the restrictions placed on graphite exports by China will further tighten the market and accelerate the demand for natural graphite, which is a key battery anode material required in all Li-ion batteries,” Johnson added.

“Given the high quality BAM results from the Burke graphite deposit, the overall metallurgical characteristics and favourable location in northwest Queensland, the Burke graphite project is very well positioned to take advantage of this expected massive growth in demand for battery anode material.”

Next steps

LEL has produced enough product to allow electrochemical testing to be undertaken.

This will provide the first cycle efficiency (discharge capacity / charge capacity), which defines the ultimate performance of the battery anode material.

Results from this testing will be released in Q1 2024.

Additionally, the laboratory testing will also provide design and target data to develop and install a BAM pilot plant, which will allow for further product optimisation and scale up metrics for production plant design to be determined.

PSG produced by the pilot plant will also be used in the BAM material pre-qualification process which is required to secure offtake agreements.

This article was developed in collaboration with Lithium Energy, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.