Stage 1 REE processing plant development work takes off at Lindian Resources’ Kangankunde project

The stage 1 processing plant is based on an initial forecast throughput of up to 440,000t per annum to produce monazite concentrate. Pic via Getty Images

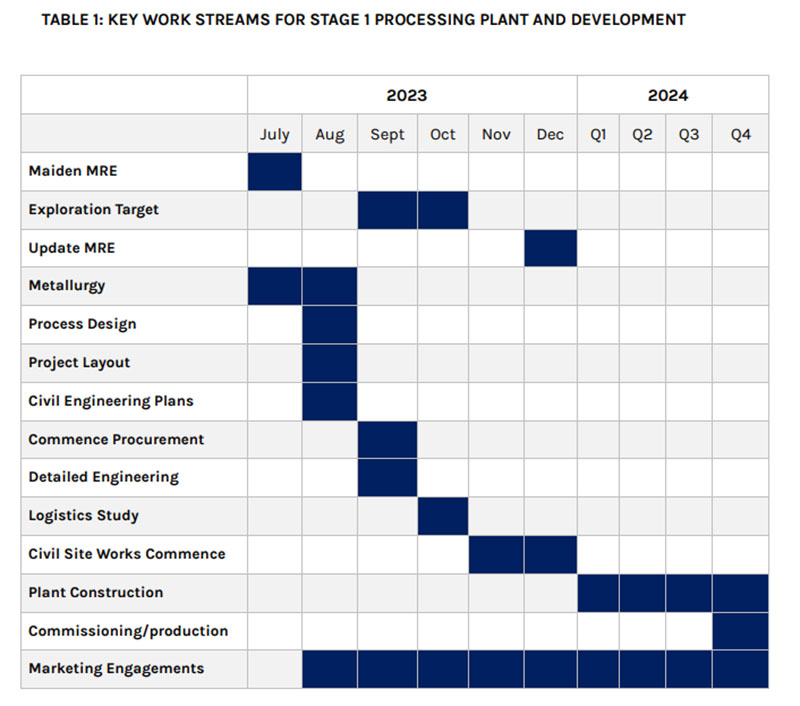

Lindian has multiple work streams advancing at the Kangankunde rare earths project in Malawi including ongoing drilling and assays, metallurgical work, and now stage 1 project design and development activities.

Stage 1 positions Lindian (ASX:LIN) as a highly and strategically meaningful monazite producer in its own right but more importantly, allows the company to rapidly establish infrastructure and supporting logistics, which will underpin the much larger stage 2 operation.

At it stands, the stage 1 plant is based on processing an initial throughput of 220,000t of material per annum to produce a monazite concentrate, expanding to 440,000t per annum thereafter.

Strategic development of a larger stage 2 operation based on a notional processing throughput of 1.5Mt per annum is expected to begin during 2024.

Opportunities abound

“This next step in project development, which is occurring eight months since we first commenced works on the ground, will form an important message to both the Government of Malawi and the local community on our commitment to develop this project consistent with the Government’s focus on mining development in the nation,” LIN CEO Alistair Stephens says.

“The opportunities that this project will provide are profound, and will benefit Malawi’s economic development, as well as improve the welfare of its citizens.”

Overview of project development activities

While work is progressing on the stage 1 plant process design, a civil works program is also being defined for engineering works across the mine laydown area, for water supply and storage, power, the 5km access road, workshops, the list goes on.

Lindian has engaged Malawian civil infrastructure group Infracon to lead the civil engineering team and undertake various surveys such as the civil geotechnical survey, and ground water survey.

Meanwhile, the current metallurgical program is expected to wrap up by the end of August.

Phase 1 metallurgy undertaken on a 130 kilogram sample resulted in the qualification of a water based gravity separation process and resulted in a recovery of 70% at a concentrate grade of 60%,.

Now, phase 2 metallurgy works are underway on two ~300kg samples over a broader surface expression of mineralisation.

Initial testwork and analysis by ALS Metallurgy has been completed to assist in establishing grinding requirements and power draw estimation.

A logistics study is also being planned to investigate expressions of interest and quotations for the transportation of mineral concentrate from Malawi to various Ports of loading and destinations.

As part of this study, Lindian will undertake third party analysis of the concentrate to independently validate the classification of the product as general goods for transport code purposes.

What else is on the agenda?

Phase 2 exploration target drilling is progressing well with the second diamond hole now at more than 500m.

Assays from both holes are expected progressively from July before phase 3 infill drilling kicks off to update a portion of the pending mineral resource estimate from Inferred to Indicated category.

This article was developed in collaboration with Lindian Resources, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.