St George Mining accelerating Araxá studies with start of metallurgical test work

St George Mining is speeding up work at its Araxá project with the start of metallurgical testing. Pic: Getty Images

- St George Mining starts metallurgical test work for niobium processing at Araxá

- Three large samples representing a range of lithologies and mineralisation to be tested

- Further work will seek to validate project’s quality and economic potential

Special Report: St George Mining is accelerating development studies at its recently acquired high-grade Araxá niobium and rare earth project in Brazil with the start of metallurgical test work.

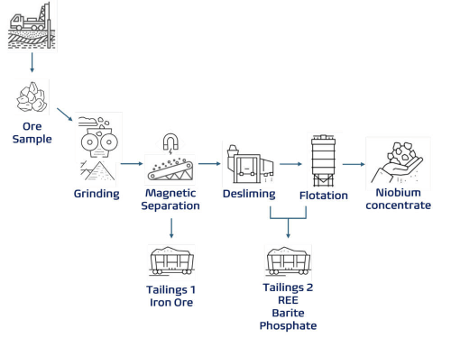

It has selected three large samples that represent a range of mineralisation from different lithological units across the project area for bench-scale testing, which will focus initially on optimising niobium and rare earth recoveries via flotation processing.

This study will be conducted under the technical co-venture between St George Mining (ASX:SGQ) and two of Brazil’s leading scientific agencies – EMBRAPII and SENAI – to ensure a reliable basis for process optimisation across the project.

Its downstream processing study will make recommendations for the potential commercial production of niobium and REE products, a critical step in finalising the plant design and project construction for a potential mining operation at Araxá.

“We are excited to now have boots on the ground at Araxá following completion of the project acquisition last week,” executive chairman John Prineas said.

“We have a number of important work programmes scheduled to commence in the coming weeks including our maiden drill campaign, geophysical surveys, geotechnical studies and downstream processing studies – as well as the release of our maiden JORC mineral resource estimate.

“We are pleased to confirm the commencement of the first phase of metallurgical testwork in collaboration with two leading scientific agencies in Brazil – EMBRAPII and SENAI – to develop a flowsheet for the processing and production of commercial niobium and rare earths products from the Araxá Project.

“In the first phase of the testwork, we will assess the potential use of new technologies in traditional flotation circuits to maximise recoveries, reduce waste and lower costs.”

Metallurgical test work

Bench-scale metallurgical testing is aimed at assessing the amenability of the project’s mineralisation to traditional flotation processing and the potential to enhance that process using new technologies.

These studies aim to define flotation parameters and recovery rates, which will guide future strategies for potential mine development and the commercial production of niobium and rare earths products as well as by-products such as magnetite, phosphate and barite.

Selected samples were obtained through a program of large diameter helical auger drilling that was executed by previous project owners in 2012.

These represent a range of different lithological units, mineralisation style and grade variations, which will provide the company with a comprehensive understanding of the mineralisation’s characteristics.

It also enables a thorough assessment of how different materials behave during the beneficiation process, supporting efforts to optimise recovery and processing efficiency.

Future testing

Metallurgical test work is the first in a three-step process to provide progressive validation of the material’s quality and economic potential whilst minimising technical risks and maximising efficiency.

This is aimed at establishing a clear pathway from raw material to market-ready niobium products and valuable by-products, supporting the project’s long-term commercial viability and optimising resource utilisation.

Future test work will focus on refining the niobium concentrate, which is traditionally achieved by leaching and/or calcining, and advancing towards conversion of final niobium products.

The follow-up work will build upon the initial testwork results to ensure that the concentrate meets the required specifications for downstream applications.

SGQ will also investigate new technologies for the refining process to optimise purity levels and evaluate different pathways for producing high-value niobium products and potential by-products during the refining process.

Additionally, future test work will focus on the potential for commercial REE production from the by-product material generated in the niobium flotation process.

This article was developed in collaboration with St George Mining, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.