Sparc to get industry pulling its coat on, with commercial graphene right around the corner

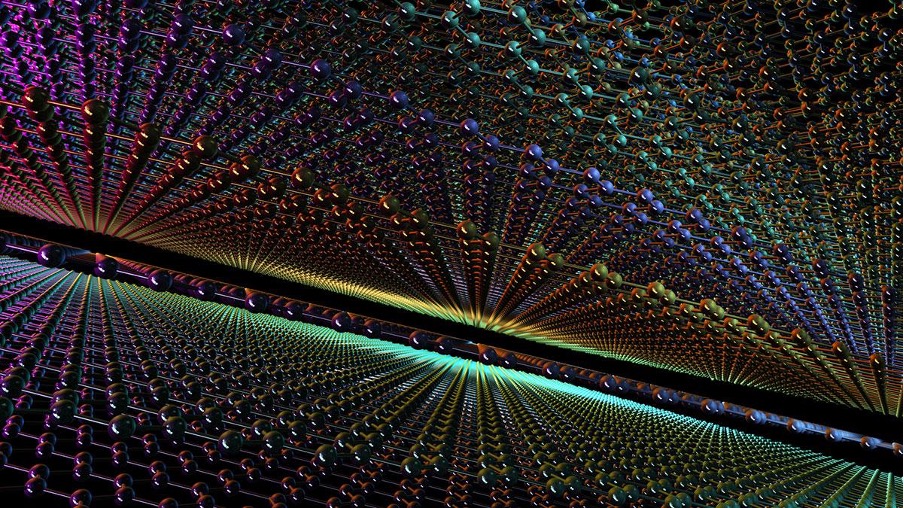

Sparc Technologies says it’s super-close to bringing its graphene-based additives to market. Pic via Getty Images.

Sparc now has a clear path towards commercial production of graphene-based additives with significant progress made in a number of key business areas.

This includes the development of a manufacturing process, the ordering of specialised graphene based additive manufacturing equipment with a manufacturing site located, and ongoing discussions underway with multiple global coatings companies regarding a potential collaboration.

Additionally, samples of its additives are now available for customer testing, while patent filing activities are continuing for protection of Sparc Technologies’ (ASX:SPN) intellectual property.

“Our path to commercialisation is now clear with detailed discussions progressing with global coatings companies,” Sparc managing director Mike Bartels says. “Comprehensive test data, undertaken to ISO standards, has now been shared under Confidentiality/Non-Disclosure Agreements and Material Transfer Agreements.

“Sparc has been able to demonstrate its know-how in addressing industry acknowledged challenges in the production of homogenous graphene dispersion having developed a proprietary manufacturing process for the commercial manufacture of graphene based additive products.

“Sparc is now poised to undertake the manufacture of graphene-based additives on a commercial scale supporting coatings companies generating significant revenue from products targeting anti-corrosive end uses.”

Graphene-based additives

Having successfully figured out the challenge of achieving homogeneous dispersion of graphene into targeted materials, Sparc is now investing in the manufacturing process with equipment identified, trialled and ordered.

Manufacturing will support a range of marketable graphene based additive products for the coatings and composites industries.

The company continues to carry out a comprehensive testing program to reinforce the significant performance improvement in epoxy coatings via the use of its additives.

It is also continuing to develop a number of graphene based coatings with applications in the energy sector, particularly in relation to its photocatalytic hydrogen project in joint venture with the University of Adelaide and Fortescue Future Industries.

This article was developed in collaboration with Sparc Technologies, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.