Sovereign Metals: Kasiya is the world’s largest ever rutile deposit with incredible 1.8 billion tonne resource

The project is a potential major source of low CO2 footprint critical minerals natural rutile and graphite. Pic: Grant Faint (The Image Bank) via Getty Images.

Sovereign Metals says it’s updated the mineral resource estimate (MRE) for its Kasiya project in Malawi – and wowzers – it’s a huge 1.8 billion tonnes at 1.01% rutile.

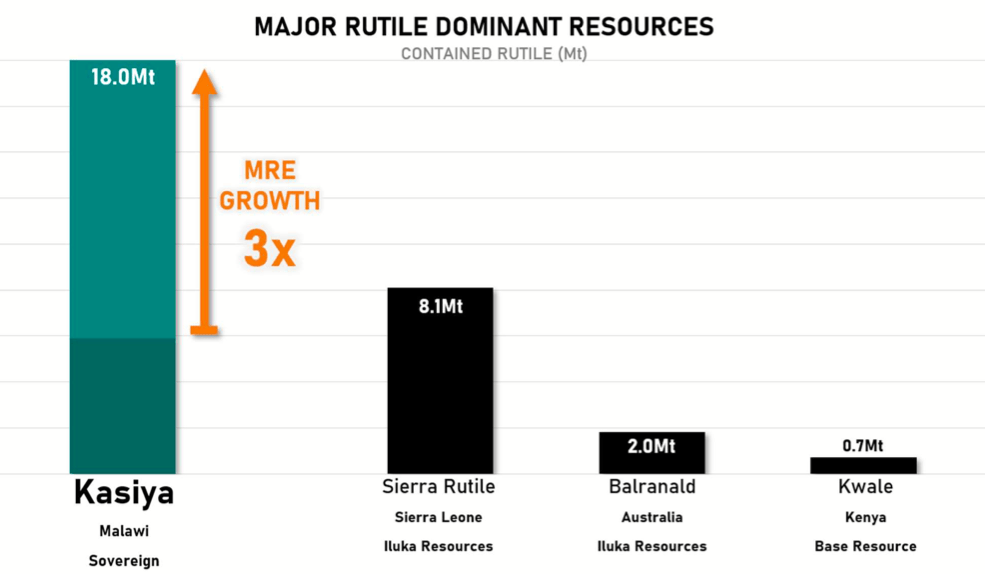

Contained rutile at the deposit now stands at 18 million tonnes – tripling the previous MRE – while contained flake graphite by-product now stands at 23 million tonnes.

A total of 662 million tonnes, or 37%, of the total MRE reports to the indicated category with remainder in the Inferred category.

The company says this puts Kasiya as a Tier 1 natural rutile deposit with more than double the contained rutile as its nearest rutile peer, Sierra Rutile.

Plus, the graphite by-product MRE at Kasiya places it as the second largest flake graphite deposit in the world.

Largest rutile discovery ever

“It is a really remarkable achievement by our team to have made the largest natural rutile discovery ever in just two years since initial identification,” Sovereign Metals (ASX:SVM) MD Dr Julian Stephens said.

“The JORC MRE of this scale and grade is clearly highly strategic, Tier 1 and of global significance in a market where natural rutile is in extreme supply deficit.”

Notably, the overall recovered rutile equivalent grade for the MRE at the global 0.7% cut-off is 1.64% RutEq (recovered rutile + recovered graphite).

Scoping study updated planned

The company will now update the scoping study to reflect the substantial MRE scale increase to examine the impact of higher grades, increased production volumes and increased mine-life.

“The step-change in scale will now allow us to examine potentially higher-grade throughput, increased production levels and a longer mine life in the upcoming scoping study update,” Dr Stephens said.

“The company is targeting a large-scale, low carbon-footprint and environmentally sustainable natural rutile and graphite operation which will also positively impact the environmental footprint of titanium pigment and other industries and provide a significant contribution to the economy of Malawi.”

The scoping study update is expected in Q2 2022, and the initial Pre-feasibility Study (PFS) is targeted for completion in early 2023.

Graphite by-product bonus

Graphite rich mineral pre-concentrate will be produced from the light fraction of the gravity spiral tails and processed in a separate graphite flotation plant to produce a high-quality flake graphite by-product with a low production cost.

A very coarse-flake and high-grade graphite product at 96% TGC can be produced via a simple flowsheet.

The Kasiya graphite is also highly crystalline and of high purity – both important features required for use in lithium-ion battery anodes.

This article was developed in collaboration with Sovereign Metals Limited, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.