Renascor secures site for battery anode material manufacturing facility

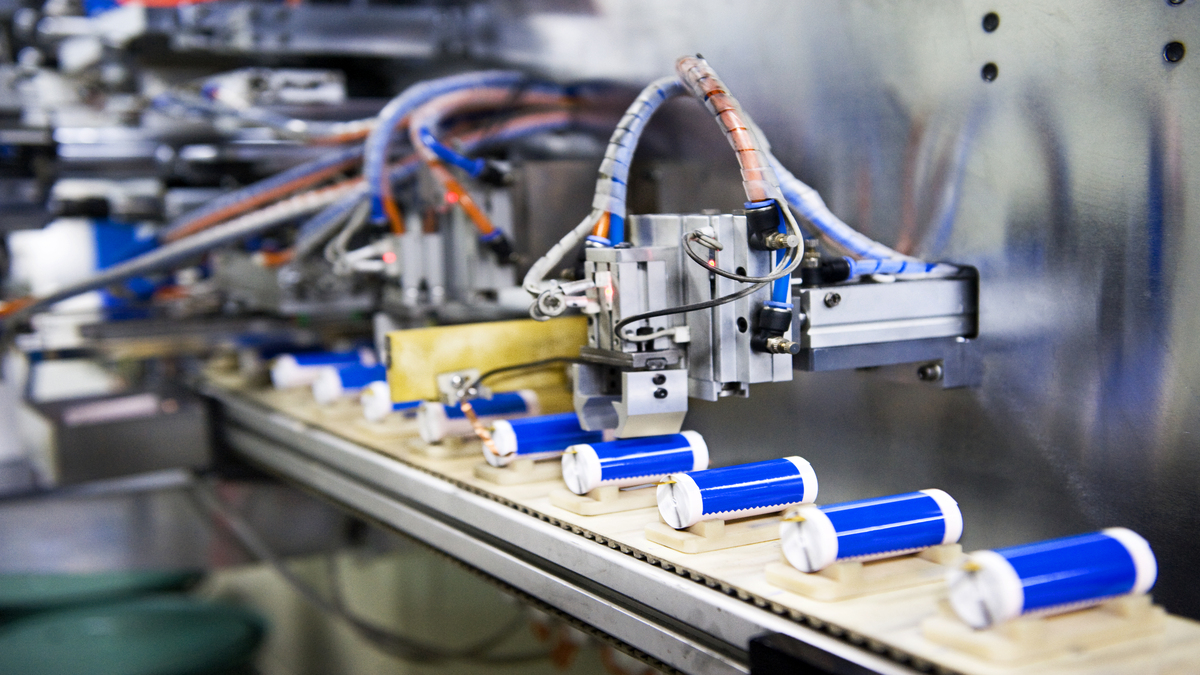

Pic: xPACIFICA / Stone / Getty Images

Renascor’s goal of becoming a major battery anode material manufacturer has taken another step forward after it secured a site from the South Australian government.

The company has executed an option-to-lease with South Australian government utility, SA Water, with initial lease options of up to 40 years for the site of its proposed Battery Anode Material facility to produce purified spherical graphite (PSG) – a key ingredient in the manufacture of lithium-ion batteries.

Renascor Resources’ (ASX:RNU) 20 hectare site in Bolivar is about 20km from South Australia’s main shipping port at Port Adelaide and is close to SA Water’s Bolivar water treatment and industrial facilities.

The site is large enough to accommodate both an increase to the originally planned Stage 1 PSG production capacity of 28,000 tonnes per annum plus additional proposed Stage 2 PSG production capacity.

“We are delighted to have executed the option-to-lease with SA Water for the site for our proposed Battery Anode Material manufacturing,” managing director David Christensen said.

“It provides certainty over a key component of our plans to become a leading producer of Purified Spherical Graphite for the growing lithium-ion battery sector.

“In securing the strategically positioned and scalable Bolivar site, Renascor will be able to leverage off the high quality of the Siviour Resource by vertically integrating the mine and concentrator with a state-of-the-art Battery Anode Material manufacturing facility to supply responsibly produced, 100% Australian-made Purified Spherical Graphite for the lithium-ion battery industry.”

Battery anode manufacturer

Renascor’s Siviour Graphite project, on the Eyre Peninsula in South Australia, is the world’s second largest proven reserve of graphite, and currently stands at 51.5Mt grading 7.4% total graphitic carbon for 3.8Mt of graphite.

This is enough to support a 40-year mine life at 150,000t graphite concentrates per annum at the project, which comprises a conventional open-pit mine and crush, grind, flotation processing circuit delivering world-class operating costs in large part due to the deposit’s favourable geology and geometry.

Graphite concentrate will then be converted into PSG using an eco-friendly processing method that will then be exported to lithium-ion battery anode manufacturers.

Next steps

Renascor is currently undertaking an optimised Battery Anode Material Study for its vertically integrated operation which will combine the planned Siviour graphite mine and concentrator in South Australia’s Eyre Peninsula with the Bolivar PSG production facility.

It is undertaking resource expansion drilling in newly secured northwestern extension of the Siviour Inferred Resource to support future capacity expansions beyond those considered in the optimised BAM Study.

The company has also finalised responses to all queries for the South Australian Department for Energy and Mining’s final approval of the Program for Environment Protection and Rehabilitation for the proposed mine and is awaiting final approval.

Additionally, negotiations on binding PSG offtake agreements – including discussion on PSG price and other material contract terms – with Renascor’s existing offtake partners is underway.

The company is also continuing discussions with other leading anode and battery manufacturers concerning potential PSG offtake.

Renascor continues to work with Export Finance Australia to satisfy conditions for its $185m loan to fund development of the Siviour project.

This article was developed in collaboration with Renascor Resources, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.