Red Metal’s Sybella trial serves up rich, potentially saleable REE concentrate

Red Metal has plated up a high-grade MREC product from Sybella ore that outshines product from ionic clay projects. Pic: Getty Images

- Red Metal impurity removal trial successfully produces MREC product with 48.7% total rare earth oxides

- Valuable magnet rare earths make up 39.5% of this TREO content and represent 92.5% of the value of TREO products

- Assays from recent step-out drilling expected shortly while optimisation of rare earths extraction continues

Special Report: Red Metal’s first proof of concept impurity removal trial has successfully produced a potentially saleable mixed rare earth carbonate product using ore sourced from the company’s Sybella discovery in northwest Queensland.

This follows interim results from Phase 2 metallurgical testing which demonstrated strong rare earth oxide recoveries on coarser heap leach crush sizes early last month, confirming that low-capex, low-opex heap leach processing could be used at Sybella.

Average extractions of 83% neodymium, 84% praseodymium, 51% dysprosium and 58% terbium were achieved from coarse chips of weathered granite.

Phase 1 metallurgical testing found the REO content could be extracted using sulphuric acid at ambient temperature, a finding backed by industry specialists from the Australian Nuclear Science and Technology Organisation.

Sybella is a unique, partially weathered and fresh REO-enriched granite that’s more than 12km long and 3km wide, offering Red Metal (ASX:RDM) the potential to uncover vast tonnages with high concentrations of valuable magnet rare earths such as neodymium, praseodymium, dysprosium and terbium.

Initial drilling starting at surface has outlined large widths of granite-hosted REO mineralisation with wide zones of >300 ppm NdPr oxide – valued for manufacturing permanent magnets used in electric vehicles and wind turbines.

Saleable MREC

The company’s first proof-of-concept impurity removal trial has now produced a MREC containing 48.7% total rare earth oxides (TREO).

Importantly, valuable magnet REOs make up a hefty 39.5% of the TREO content and represent 92.5% of the value of TREO products in this concentrate.

Likewise, critical heavy REOs make up 26.6% of the value of TREO in the product.

The whole metallurgical process from ore leaching to rare earth carbonate precipitation process achieved high recoveries of MREOs with 75% Nd, 76% Pr, 52% Tb and 45% Dy recovered along with very low levels of uranium, thorium and iron.

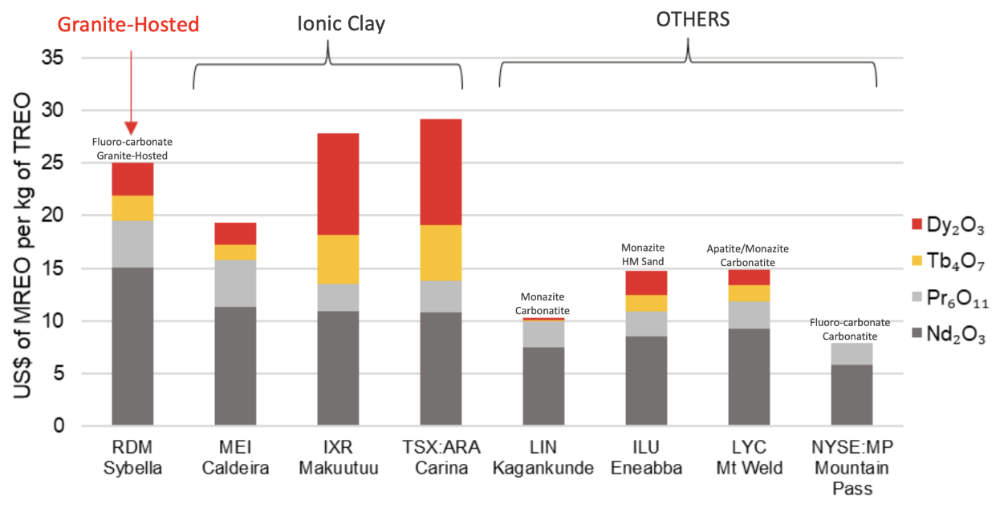

This is a higher MREO grade, higher MREO/TREO ratio and higher HREO/MREO ratio than MREC products from industry-leading ionic adsorption clay projects, RDM says.

RDM expects additional improvements in downstream recovery and MREC purity once further optimisation is applied to the higher purity leach liquors derived from the current pH 3 and 3.5 test work.

“Impurity removal and precipitation of a saleable product with minimal REO loss is an important hurdle to clear for both the granite-hosted Sybella and ionic clay-hosted deposit types,” Red Metal managing director Rob Rutherford said.

“As such, success with our first impurity removal attempt is a major step forward for the Sybella REO discovery as it shows the essential indicators are in place to cost effectively produce a quality MREC product.

“The company is very confident that our ongoing studies will confirm a process route that optimises REO recovery (increases revenue) while reducing the acid consumption rate and ensuring that impurities in the final product are satisfactorily minimised (lowering processing costs).

“Success with the studies would give confidence that a premium MREC product could be delivered with low operating costs.”

Ongoing work programs

RDM will continue work to seek the most cost-effective process for REO extraction while providing a more certain indication of the Sybella project’s size and grade potential.

Assays from over 8,000m of broad step-out drilling recently completed over a 24km2 area of the project are due shortly.

Follow-on column leach test work and additional bottle roll tests using very weak acids (pH 2 to pH 3.5) run over extended residence times (>120 days) are also underway.

The company also plans to carry out infill resource drilling later this field season.

This article was developed in collaboration with Red Metal, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.