Rare earths major Lynas has eye on ionic clays in the hunt for heavies

Pic: Via Getty

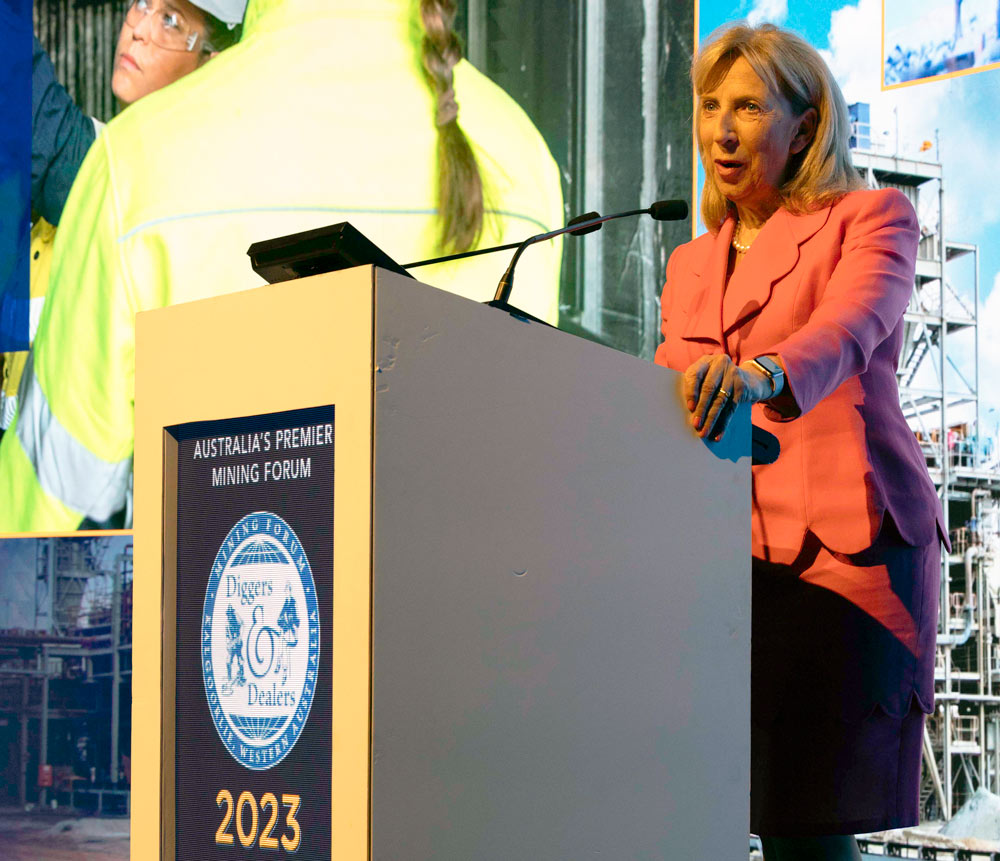

- Finding complementary clay deposit for Mt Weld mine “certainly what we are looking at”: LYC boss Amanda Lacaze

- LYC “always open to partnering, offtake agreements, and acquisition”

- Prices for a range of rare earths recently hit their lowest point since 2020; long term demand projections still bullish

Lynas (ASX:LYC) is running the ruler over acquisitions, including ionic clay projects, to enhance flagship hard rock operations at Mt Weld in WA.

The 15 rare earths are categorised into ‘lights’ and ‘heavies’. Heavies are generally less common and more expensive.

The ionic clay deposits, while very low grade, typically have more of the heavies, which are used in the production of high-performance permanent magnets.

Rare earth permanent magnets are a crucial component in wind turbines and in the drive train of hybrid and electric vehicles.

There’s a couple of kilos of rare earths magnets in every EV, and about a tonne in every MW of power produced by wind turbines.

China, which dominates global REE mining and processing, gets most of its supply from ionic deposits in Southern China and neighbouring Myanmar.

Finding a complementary clay deposit for the light-dominant Mt Weld “is certainly what we are looking at”, LYC boss Amanda Lacaze told Stockhead at the Diggers & Dealers Mining Forum in Kalgoorlie.

“Ionic clay processing has had a bad rep for many years for the way it was originally prosecuted in China, where they basically just pump the earth full of ammonium sulfate and catch the minerals as they leached out,” Lacaze says.

“But there are better ways of doing it today. It will remain an important source.”

READ: Why are ASX stocks so in love with clay rare earths projects? An incomplete punter’s guide

Lacaze says LYC – the Western world’s only rare earths producer of scale — is always open to partnering, offtake agreements, and acquisitions.

“It is to our benefit for the whole of the industry outside of China to grow,” she says.

Is there room for another large Western rare earths producer?

LYC currently building out its mining and downstream capacity across the world. But the road was a tough one, partially due to China’s tight control over market pricing.

Lacaze was the driving force behind the revival of LYC, which death-spiralled from multi-billion-dollar highflyer in 2011 to a valuation of just $3m in 2015.

It is now worth $6.5bn.

“We’ve been in production for a decade and have faced every type of challenge that could be thrown at us,” Lacaze says.

“I hope there is room for more Western companies because the textbooks are right – monopoly markets are not healthy markets. With more competition everyone in the industry benefits.

“But the barriers to entry are high. New entrants will need to be creative in the way they enter the market, but I am hopeful we will have a more robust outside-of-China market industry.”

Rare earths prices down, but Diggers presenters upbeat

Prices for a range of rare earths recently hit their lowest point since 2020, thanks to soft downstream demand and China’s dominant influence on pricing.

Meanwhile, long term demand is still expected to grow strongly from 260-280,000tpa REO in 2022 to 340-370,000tpa in 2027.

Of that, magnet rare earths are the major growth driver. There is an “onwards growing deficit” of magnet rare earths from 2023 onwards, says Australian Rare Earths (ASX:AR3) non-exec chairman Professor Dudley Kingsnorth.

By 2030, that deficit could reach 20-40,000tpa – a significant figure.

Learning from an abysmal success rate

The historic failure rate amongst Western companies is very high, however.

“In 2010-11, there was $15bn raised between US, Australia, and Canada. There were 60 rare earths companies and about 100 projects,” Kingsnorth says.

“There were only two projects built. One was LYC, which needed another $2bn to complete.”

“That’s why investors are very nervous about investing in rare earths projects.”

To be successful, the new generation of stocks must establish themselves in the emerging ex-China, high-end rare-earth magnet supply chain.

It is a huge undertaking. Goldman Sachs recently estimated a cost of $US15-$US30 billion to establish a 50,000tpa ex-China market involving mines, refineries, metal production and magnet processing capacity.

“When you talk to [OEMs, car makers] they realise that the dysprosium and terbium is really very important, to have an availability of that so they can put it in their magnets,” Kingsnorth says.

“At the moment, all the dysprosium and terbium comes out of China, and a lot of that comes out of Myanmar. You can see the conditions under which that is mined.

“With prices where they are today it is difficult to build a new mine. What we need to do, what Australian mining needs to do is get off our arse and talk to and partner with these original equipment manufacturers.”

Very soon legislation will come into force in the EU where companies will have to provide lifecycle information on the magnets, which mostly starts in Myanmar mines.

“We have to explain to OEMs that they need to look at their supply chain,” Kingsnorth says. “[China] has desecrated an area the size of Singapore [in Myanmar] in the recovery of these ionic clays.”

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.