Processing option shows De Grey’s Tier-1 Hemi mine will be world class on gold production and ESG

Pic: Bongarts via Getty Images

A proven processing pathway for De Grey Mining’s 10.6Moz Mallina gold project will stamp it as a new Tier-1 mine, not just on its massive production profile but also for its ESG credentials and low carbon intensity.

Pre-feasibility study work by consultants Wood Australia has outlined a preferred processing path for the world class Hemi discovery and broader Mallina gold project, which will hit high gold recoveries of between 93- 95% and reduce CO2 emissions compared to alternative processing methods by 25%.

The mix of comminution with high pressure grinding rollers (10Mtpa) and pressure oxidation (0.8Mtpa) will result in 20% lower energy consumption and 25% lower lime reagent consumption with lower capital and operating costs.

A scoping study released by De Grey (ASX:DEG) last year outlined a 10-year operation which would produce an average of 473,000oz a year over its first five years, but drilling since that announcement last October boosted resources at Hemi from 6.8Moz to 8.5Moz, with measured and indicated resources up a staggering 80% to 6.9Moz at Mallina and 5.8Moz at Hemi.

That means the PFS due for release in September is likely to boast even better numbers, with the costings for the processing method part of a comprehensive process to ensure robust pre-production numbers for Australia’s next world class gold mine.

The best technical, environmental and economic outcome

De Grey says further studies aim to reduce the carbon intensity and greenhouse gas emissions profile of Hemi and Mallina.

Managing director Glenn Jardine said the technologies favoured by the trade-off study are robust and well-proven.

“The use of a HPGR in the comminution circuit and POx for the oxidation circuit represent the best technical, environmental and economic outcomes for a proposed plant of this scale,” he said.

“HPGR and POx are robust, well proven and accepted technologies that have been chosen after extensive testwork. Pressure oxidation demonstrated lower reagent usage and carbon intensity, lowest greenhouse gas emissions and the highest gold recovery of the processing options considered for Hemi mineralisation.

“We will carry the selected process flowsheet through the Pre-Feasibility Study currently underway and due for completion in the September Quarter, 2022. The significant increase in the scale and confidence level of Mineral Resources along with the robust flowsheet selected for processing at Hemi enhance and de-risk the project.”

How does the flowsheet work?

So how will the gold get from the ground into those shiny (and very valuable at over A$2,600/oz) gold bars?

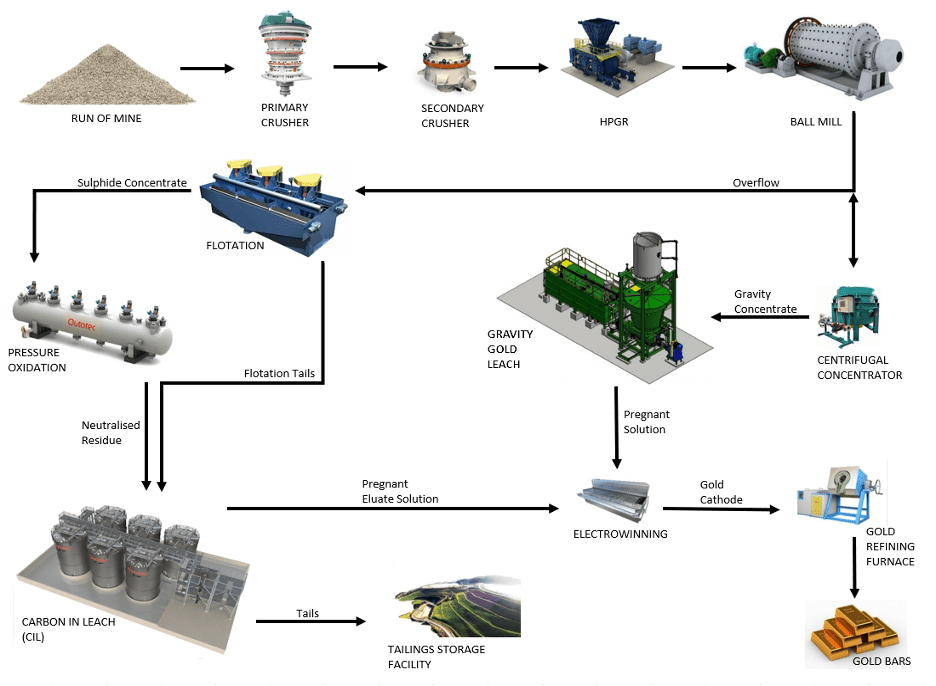

It’ll look something like this.

The easiest gold to extract from the ore will be recovered through gravity after the ore is crushed and fed through high pressure grinding rollers and a conventional ball mill.

HPGR is a proven technology, used successfully at Boddington and Tropicana, two of WA’s biggest gold mining operations.

The gravity concentrate will be leached into a pregnant solution, before gold cathode is produced from electrowinning and sent to the refining furnace to be melted into gold bars.

The majority of the Hemi ore will be floated into the low mass pull concentrate that recovers high levels of sulphides and gold before the pressure oxidation process, with the flotation tail containing gold that can be recovered through CIL.

De Grey says the oxidation circuit will have lower reagent consumption and shorter residence time than other options like ultra fine grinding and atmospheric oxidation, or bacterial oxidation.

“Additional advantages of the POx option are the robustness of the process, the long history of this methodology coupled with reliability improvements over the past two decades, both in materials of construction, operability, maintenance and delivery times,” the company said.

Through this processing route Hemi will have a very attractive mineral recovery rate of 93-95% at expected mined grades.

Extensive testwork in batch and more recently pilot plants have validated De Grey’s chosen process flowsheet, with additional bench and pilot scale optimisation test work to be undertaken.

This article was developed in collaboration with De Grey Mining, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.