Podium testwork highlights potential processing pathway

Podium says it’s confirmed a way forward for producing saleable PGM concentrate at Parks Reef. Pic via Getty Images.

Podium has ticked off another box on its checklist after testing confirmed the ability to produce a saleable platinum group metals concentrate using ore from its Parks Reef project.

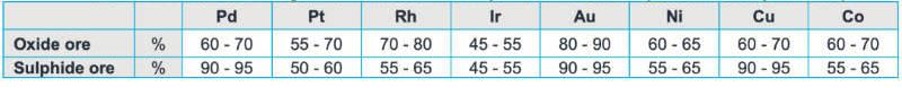

Adding further interest, the company has achieved high recoveries for all eight payable metals of up to 85% using atmospheric leaching.

Podium Minerals (ASX:POD) noted that metal recovery from the leach solution can produce a high-grade PGM product suitable for refinery feed.

The news is encouraging for future development for the project, which recently saw a doubling of contained 5E PGMs to 6Moz along with 94,000t of copper, 127,000t of nickel and 24,000t of cobalt.

“Extracting high metal recoveries via the leach process to create a product suitable as a PGM refinery feed is a significant milestone for Podium and our shareholders. The leach test work has successfully demonstrated recovery for both oxide ore and sulphide ore,” managing director Sam Rodda said.

“Leaching test work, when compared to the flotation process, could deliver a step change in unlocking value for Parks Reef due to the potential for Podium to produce a higher-grade product attractive to PGM refineries globally. This process offers new potential avenues to develop our project and routes to commercialise our product.

“Further metallurgy work will investigate optimisation of our product suite considering existing refineries, customers and end-markets. We believe that one of the key benefits associated with a high-grade refinery product would be the ability to drive the marketability and stewardship of the products produced from Parks Reef.

“Supply chain provenance is becoming more important globally for downstream off-take parties and customers sourcing feedstock for their PGM and Base Metals refineries, and Podium is positioning itself to be a responsible and stable supplier of PGMs to the global market.”

Flotation and leach testing

Flotation testing by leading PGM engineering group DRA Global produced a concentrate suitable for sale to a PGM smelter by removing waste material.

This achieved recoveries of up to 85% for palladium, platinum, gold and copper, 65 for rhodium and iridium, 60% for nickel and 50% for cobalt using ore sourced from the sulphide zone, which starts from a depth of about 45m and continues to the base of the orebody.

Additionally, further work has indicated that flotation can produce a high recovery feed suitable for a subsequent hydrometallurgical process. This potential processing path will be considered in conjunction with ongoing leach tests.

Testing of the oxide ore, which resides from surface to about 45m depth, will be tested under separate flotation conditions specific to oxide minerals after failing to deliver acceptable returns through standard flotation tests.

Meanwhile, in addition to the successful flotation concentrate an atmospheric leach process has been selected as the most effective means of extracting PGM and base metals from the ores to target high grade products that can bypass traditional smelters and target international refineries.

This has achieved high recoveries from both the sulphide and oxide ores, which would potentially simplify any plant layout and offer the opportunity to treat ore that is not typically included in a standard flotation circuit.

Current work

Sighter laboratory tests have commenced on metal recovery from the leach solutions produced using atmospheric leaching to develop options for the Parks Reef final product mix.

A preferred metal recovery pathway is under development for the production of PGMs and base metals, this includes the potential to expand the final products to include copper and a nickel-cobalt hydroxide.

This article was developed in collaboration with Podium Minerals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.