Petal to the metal: How ‘phytomining’ could transform mine waste into big $$

Pic: Getty

‘Harvesting’ high grade metals – such as nickel, gold, and cobalt — from plants just like any other crop is called phytomining, and there’s a lot of research happening right now to turn this into a commercial reality. But how does it work?

There’s a select group of so-called ‘hyperaccumulator’ plants which have the unusual ability to absorb and concentrate metals from soil at high levels.

And we mean high levels.

In 2000, the US Department of Agriculture found that ash from pennycress grown on high-zinc soil in Pennsylvania yielded 30 to 40 per cent zinc.

And in Malaysia, a whole range of hyperaccumulator plants have been identified, some with up to 16 per cent nickel in their sap.

These grades put best deposits in the world to shame.

Despite being around for many decades, the concept remains in research phase and is yet to be rolled out on a commercial scale. But the advantages are compelling.

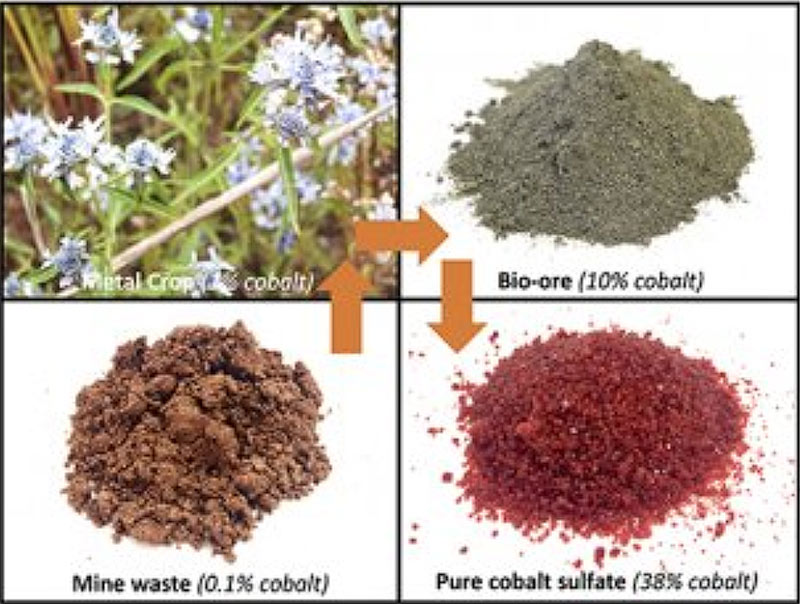

Phytomines can complement existing mining operations by monetising super low-grade orebodies or mine tailings (waste) in an environmentally friendly way.

A hyperaccumulator crop could be grown over low-grade mining waste, for example, then periodically harvested and allowed to regrow.

The harvested biomass is dried and burnt to generate a plant ash called bio-ore, which contains the super high-grade metal content.

This bio-ore boasts a higher metal content than a conventional ore, which means it needs less space for storage and transport.

And it could also be used as a cost-effective remediation tool (called phytoremediation) — an approach that has been used successfully around the world.

This 2009 study concluded that that an Australian nickel phytomine could make about $11,500 in clear profit per hectare, per harvest if energy generation from the harvested biomass was also utilised. A gold phytomine could make $26,000 per hectare.

UQ’s Sustainable Minerals Institute (SMI) researcher Dr Philip Nkrumah is currently developing phytomining technology at the Centre for Mined Land Rehabilitation.

He says mine tailings represent “some of the largest untapped resources globally”.

Tapping into this waste through phytomining not only creates additional revenue streams, it offers a sustainable solution to supply-side issues the industry is going to face, he says.

“Some species of plants can contain up to one per cent cobalt or four per cent nickel in their shoots, translating to more than 25 per cent metal in their ash which is dubbed ‘bio-ore’,” says Dr Nkrumah.

And the high purity of bio-sourced metals makes them especially suited for applications like lithium-ion batteries, Dr Nkrumah says.

“Cobalt consumption is projected to rise by between eight and ten per cent annually but supplies are likely to be limited by 2050, so the industry needs to identify additional sources,” Dr Nkrumah says.

“Phytomining is an innovative solution because it complements the global supply chain for critical minerals like cobalt, while promoting the circular economy by utilising mining waste.”

- Subscribe to our daily newsletter

- Join our small cap Facebook group

- Follow us on Facebook or Twitter

Dr Nkrumah told Stockhead that, in most cases, biomass would be harvested annually, either by harvesting whole plants, or by ‘coppicing’ woody plants. And it’s a pretty simple processing proposition, too.

“The process is relatively straight forward because of the high-purity of the starting material (bio-ore),” he says.

“We are currently developing more innovative recovery techniques to further simplify the process while increasing efficiency.”

Dr Nkrumah and his team have been doing intensive phytomining fieldwork at MMG’s Dugald River mine in Queensland; one of the biggest zinc operations in the world.

“Our fieldwork at the Dugald River mine in Central Queensland has led to the discovery of species with potential for application in phytomining, including the zinc hyperaccumulation in the native legume Crotalaria novae-hollandiae,” Dr Nkrumah says.

“Takeaways from our experimental work are: i) the tested species is well adapted to the mineralised substrates and climatic conditions at Dugald River, ii) the plants could be easily propagated via seeds or cuttings, iii) the plants are able to produce high biomass which is a key requirement for economic phytomining, and iv) the plants accumulate high concentrations of zinc in the shoot, sufficient to support phytomining activities.”

So what are the next steps toward ‘commercialising’ this tech?

“To build the case for the minerals industry, a large-scale demonstration is needed to work through operational challenges and provide “real-life” evidence of profitability,” Dr Nkrumah says.

NOW READ: Gold — It DOES grow on trees, and this company is hitting paydirt by scanning leaves

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.