Marenica uranium test slashes acid consumption at Angela by 77%

Pic: Bloomberg Creative / Bloomberg Creative Photos via Getty Images

Special Report: Marenica could greatly lower the cost of producing uranium from its Angela project with its proprietary beneficiation process slashing acid consumption.

Acid consumption is one of the biggest costs in the production of uranium and the application of the company’s U-pgradeTM process to an ore sample from the project in the Northern Territory has reduced its use by about 77 per cent to just 24 kg per tonne.

Marenica Energy (ASX:MEY) says this was achieved by removing the bulk of the acid consuming minerals – particularly calcite that is abundant at Angela – prior to acid leaching.

Additionally, the removal of calcite prior to acid leaching also improved uranium extraction by 2.8 per cent to 96 per cent though the company cautioned that the mechanism for this increase is still under investigation.

Managing director Murray Hill says the reduction in acid consumption is a great result that demonstrates significant operating cost savings that could make Angela economically viable at significantly lower uranium prices.

“These potential cost savings are likely far beyond the prevailing expectations of the time when Marenica acquired the project,” he added.

“These results clearly demonstrate the potential Marenica has to add value to its uranium assets through U-pgradeTM, and gives us a sustainable competitive advantage over our peers.

“This result also indicates the broader potential application of U-pgradeTM beyond the calcrete hosted uranium ores of Namibia, on which this ground-breaking patented process was developed.”

Hill also noted that the isolated calcite mineral component of the ore could potentially be used to neutralise and render the leach residue inert, which is a significant environmental benefit.

Uranium testwork

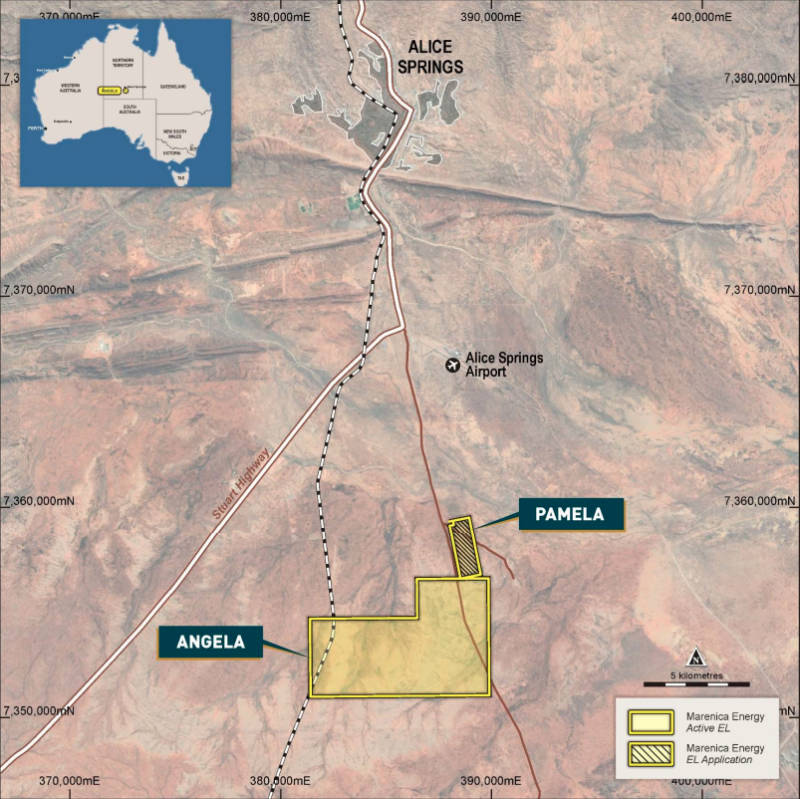

The Angela project in the Amadeus Basin about 25km south of Alice Springs has estimated calcium grades of about 4 per cent, which is equivalent to 10 per cent calcium carbonate (calcite).

This calcite content – a major acid consuming part of the orebody – has been a stumbling block for any potential development of the project as metallurgical test work by previous owners had indicated that acid consumption would be between 100kg/t to 120kg/t.

At current acid prices of about $400/t, this would contribute to high operating costs for any potential development of Angela.

Here is where Marenica’s U-pgradeTM process steps in.

A composite sample of material from Angela that had acid consumption of 104kg/t, was subjected to U-pgradeTM, which successfully removed the bulk of calcite, resulting in 91 per cent of the mass and 16 per cent of the calcite reporting to the leach stage.

The successful removal of the bulk of the calcite reduced the acid consumption to 24g/t, which the company says will substantially lower operating costs.

Other benefits include the environmental benefit from using the removed calcite to neutralise acid in leach tailings as well as the possible reduction in size of the acid storage facility and reduced leach circuit volume, which could reduce both capital and operating costs.

There is also potential to further increase calcite removal and reduce uranium lost to the rejection fraction through a detailed optimisation testwork program.

Angela has an inferred resource of 30.8 million pounds of uranium at a grade of 1,310ppm.

If you would like to learn more about Marenica’s upcoming activities, please register here for Marenica’s upcoming Investor Briefing with Managing Director Murray Hill.

This article was developed in collaboration with Marenica Energy, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.