Magnet REE recoveries of up to 86% indicates OD6 Metals is onto the right type of clay-hosted play at Grass Patch

Grass Patch’s magnet REE recoveries are soaring high. Pic via Getty Images

- Grass Patch metallurgical testing returns better than expected 86% recovery of magnet rare earths

- Test work used standard slurry density adopted by ANSTO for all clay-hosted rare earth projects

- Results confirm that further targeted drilling should be carried out at the Belgian, Circle Valley and Scaddan prospects

Special Report: Metallurgical testing at OD6 Metals’ Grass Patch clay-hosted rare earths project near Esperance, WA, has returned better than expected recoveries of up to 86% magnet rare earths.

Grass Patch is ~30-100km north of Esperance and hosts extensive calcrete formation up to 30cm in thickness.

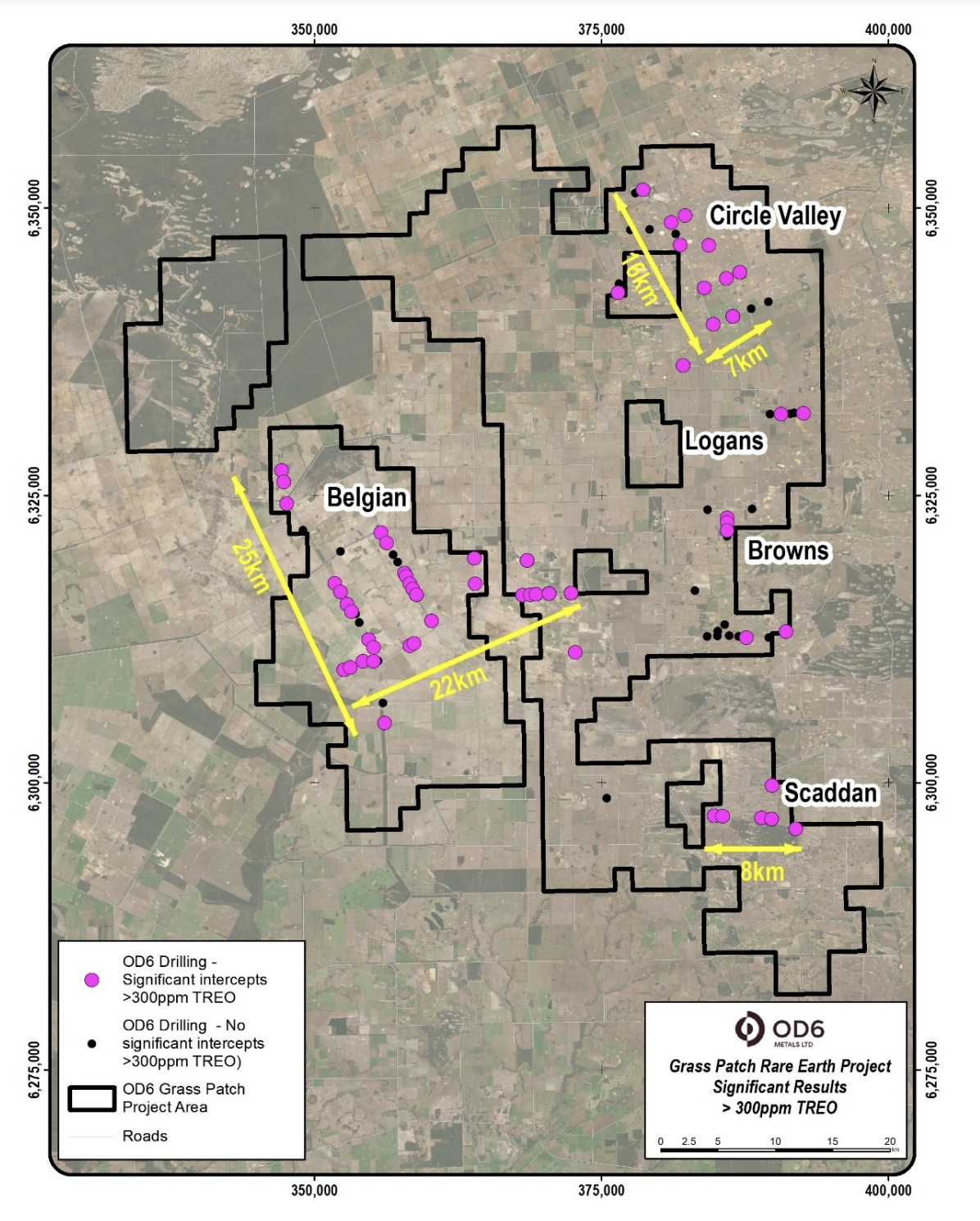

Reconnaissance drilling by OD6 Metals (ASX:OD6) has successfully identified high-grade clay-hosted rare earth elements (REEs) with grades of up to 3,340ppm total rare earth oxides (TREO).

The 93-hole program also encountered thick clays of up to 59m.

Magnet rare earths (MagREE) are used in the manufacture of permanent magnets found in electric vehicle motors and wind turbines.

Metallurgical testing success

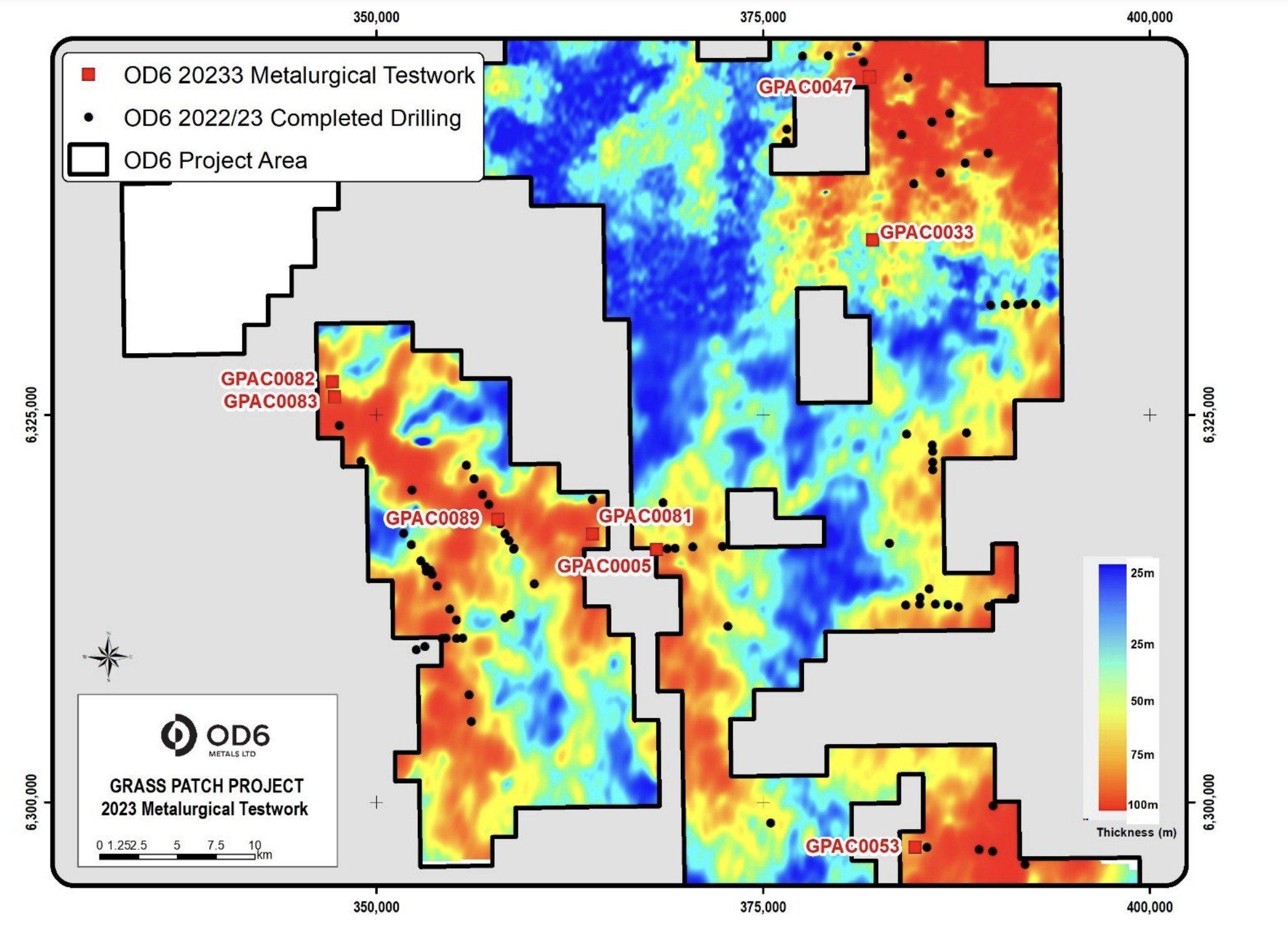

Eleven samples from Grass Patch returned average MagREE recoveries of 69% – inclusive of neodymium, praseodymium, dysprosium and terbium – using a relatively weak 25g/l concentration of hydrochloric acid.

This work achieved a top recovery of 86% at the Belgian prospect, while testing of samples from the Circle Valley prospect returned the highest average recovery of 78%.

“Whilst our focus over the last 12 months has been firmly on our world-class Splinter Rock project, we have continued to leverage that work and apply it at Grass Patch,” OD6 managing director Brett Hazelden said.

“It is pleasing to report that all eleven metallurgical samples sent to ANSTO have surprised us on the upside of our expected metallurgical leach recoveries, with each of the fifteen rare earth elements also being broadly equally recovered which is one of our key tests for clay projects to be potentially successful.

“The results confirm further targeted drilling should occur primarily at the Belgian, Circle Valley and Scaddan Prospects.

“We have utilised our new bottle roll technique, developed in conjunction with ANSTO, designed and calibrated to reflect an equivalent six hour stirred reactor leach. With reference to the low slurry density used, it is important to highlight this is the standard slurry density used by ANSTO for all clay hosted rare earth projects inclusive of acid soluble and ionic diagnostic leach tests.

“As we progress further bench scale testing, it is anticipated that a slurry density of between 25% and 30% is likely to be optimal, as recorded on a number of other projects, with little to no decrease in leach recoveries.”

Further work

OD6 plans to carry out additional Phase 2 recognisance drilling over the Belgian, Circle Valley and Scaddan prospects.

This will be followed by additional sighter bottle-roll tests using selected Phase 2 drill samples.

This article was developed in collaboration with OD6 Metals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.