Lotus testing ore sorting technology on Kayelekera uranium feed

Pic: Bloomberg Creative / Bloomberg Creative Photos via Getty Images

Ore sorting testwork is now underway at Lotus Resources’ Kayelekera uranium project, with significant improvements to project economics a possible outcome.

Some 500kg of run-of-mine ore from the Malawi project has been transported by Lotus (ASX:LOT) to Perth for testing at a facility run by STEINERT.

STEINERT is a leader in the magnetic and sensor separation industry, providing Lotus ore sorting expertise and experience as it explores the capabilities of the technology at Kayelekera.

The process, which sorts feedstock and rejects high acid consuming gangue minerals and waste rock, has the potential to reduce operating costs, increase annual production by upping feed grade, and extend mine life by enabling the processing of low-grade stockpiles.

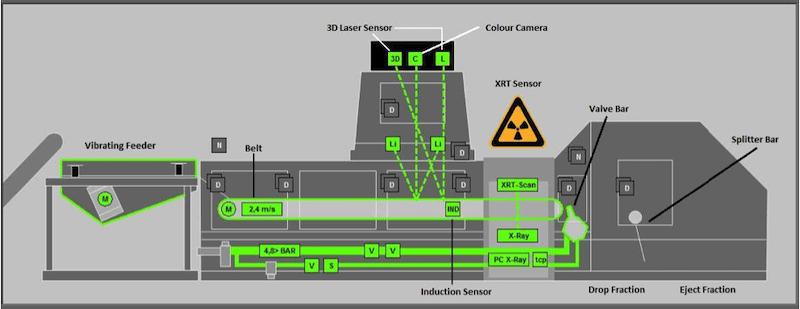

Applied before the material is fed to a mill, the equipment uses sensors to detect valuable ore and sorts it into a product stream using a compressed air valve bar, separating it from rejected feedstock.

There are a number of sensors available for use, and the current testwork combines x-ray transmission, optical and laser systems.

While not essential for the project’s recommencement, Lotus is exploring the tech as a means of improving its overall economics.

Managing director Keith Bowes said ore sorting had come a long way since Kayelekera – previously operated by Paladin between 2009 and 2014 for 11 million pounds of uranium output – was last an operating mine.

“When Kayelekera was last in production, ore sorting in the mining industry was in its infancy,” he said.

“Since then, the technology has advanced significantly, with far greater scope and a wider range of applications through improved detectors and faster data processing, which makes the technology more suitable to higher throughput applications seen in the mining industry.

“Ore sorting is not essential for the Kayelekera mine to recommence production, but it has the potential to significantly improve the economic returns, by reducing operating costs, increasing annual production and extending the mine life.

“Whilst trial work has only recently commenced, we are very encouraged by preliminary results, which show the ore is clearly amendable to the technology.”

Testwork on the technology will continue over the coming months, with the results to be incorporated into a feasibility study.

Part of the plan

In conversation with Stockhead earlier in 2021, Bowes raised the potential of ore-sorting as an option to explore for Lotus as it eyes a Kayelekera restart.

The technology was identified as one of four pillars of improvement being explored by Lotus to further strengthen Kayelekera’s numbers.

Lowering acid consumption, reducing the cost of power generation and optimising the existing tailings dam were the other pillars being considered.

Lotus owns 85% of the Kayelekera project, with the Malawi government holding the remaining 15%.

This article was developed in collaboration with Lotus Resources, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.