Lithium Universe’s engineering study on Québec refinery off to a flying start

Lithium Universe’s proposed refinery will produce battery-grade lithium carbonate, similar to that from the Jiangsu lithium carbonate plant. Pic via Getty Images

Special Report: Lithium Universe says the engineering study by Hatch on its Québec Lithium Processing Hub (QLPH) multi-purpose, battery-grade lithium carbonate refinery is progressing at an outstanding pace.

This study is focused on a 16,000tpa battery-grade lithium carbonate plant at or around 5.5% Li2O with the final lithium carbonate product at least 99.5% and 99.9% grade.

Lithium Universe (ASX:LU7) has made the deliberate choice to focus on lithium carbonate rather than lithium hydroxide because the team has an imbedded expertise from the Jiangsu Refinery and also due to its widespread use in the fast-growing lithium-iron-phosphate (LFP) battery industry.

LFP batteries are increasingly used in EV applications due to their lower costs, longer shelf life and superior stability, compared with lithium hydroxide.

In addition, anhydrous sodium sulphate, generally used in the textile industry, will be sold as a by-product and alumina-silicate residue from the leached spodumene will be sold to the cement industry.

The flowsheet design has now been finalised, along with a draft site layout.

Setting the stage for the DFS

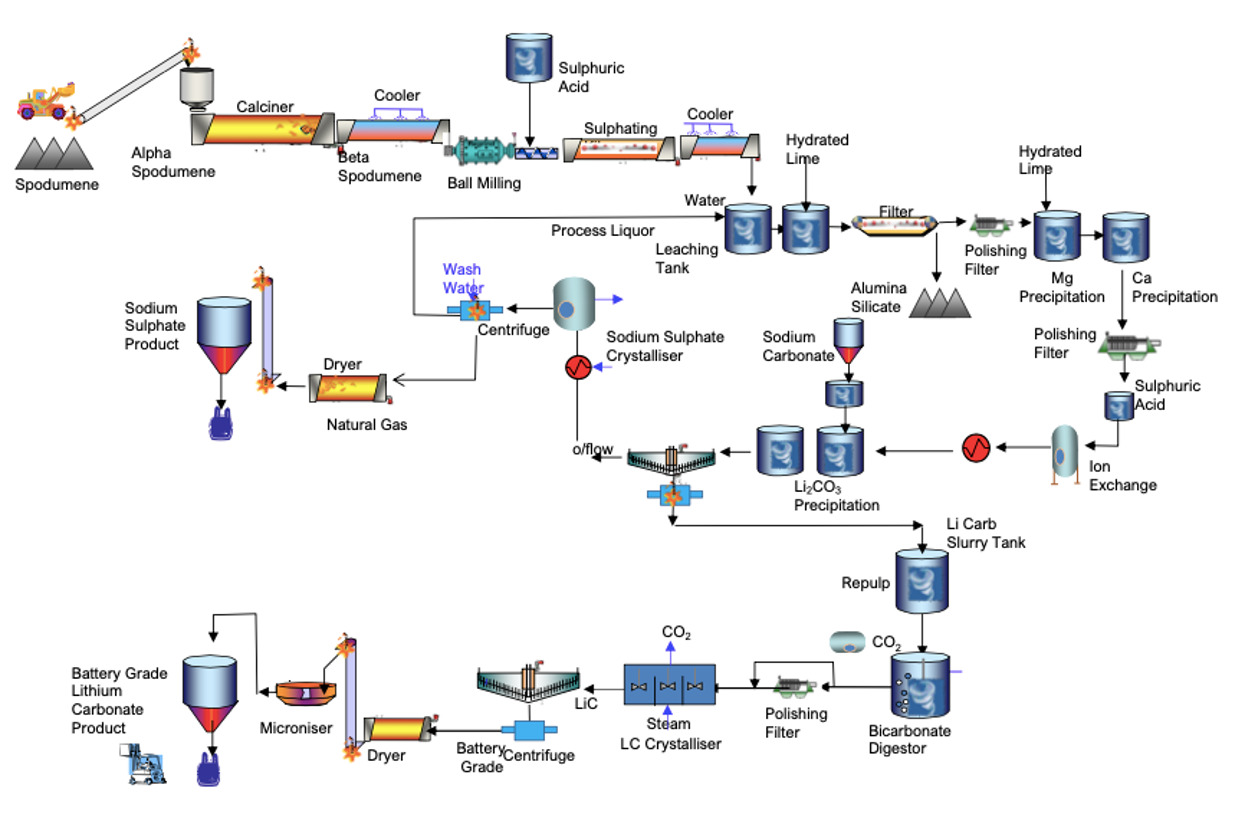

So far, the Hatch study team has provided a Block Flow Diagram (BFD) and Process Flow Diagrams (PFD), along with Mass Balance and Process Design Criteria (PDC), which showcase mass flows, splits and anticipated tonnages concerning significant equipment.

The design includes the use of conventional kiln conversion of spodumene, sulphuric acid sulphation and leaching, impurity removal and final purification to battery-grade quality lithium carbonate, similar to that produced from the Jiangsu lithium carbonate plant.

However, this design is more robust and capable of processing various types of spodumene concentrate from Canada and around the world.

“The progress of the engineering study for the QLPH lithium refinery by Hatch has been excellent, setting the stage for the DFS,” LU7 chairman Iggy Tan said.

“Considering our listing in early August this year, the pace and quality of work demonstrated by Hatch, guided by the company’s lithium dream team, has been pleasing.”

Doubling down on preferred locations

Hatch also completed a location study for the optimal site selection for the proposed refinery, which involved an evaluation of various potential locations, with more than 20 municipalities contacted, and relied on recent site location benchmarks from both 2021 and 2023.

Based on the location study, LU7 has opted to concentrate on the Bécancour Industrial Park between Québec City and Montreal.

The company has initiated discussions with the Société du parc industriel et portuaire de Bécancour (SPIPB) concerning the Bécancour Industrial Park.

This article was developed in collaboration with Lithium Universe, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.