Liontown launches DFS and downstream study for Kathleen Valley lithium project, shares dive

Pic: Tyler Stableford / Stone via Getty Images

Liontown Resources (ASX:LTR) is up 600% or so over the past 12 months, so plenty of anticipation was building for the launch of the DFS on its Kathleen Valley lithium project in WA.

Those numbers are now out, detailing a massive scale lithium mine in the same league in spodumene production terms as major producers like Pilbara Minerals (ASX:PLS) and Wesfarmers (ASX:WES) and SQM’s proposed Mt Holland mine.

Liontown says it will cost around $473 million to build Kathleen Valley as a 2.5Mtpa processing operation, producing around 511,000tpa of 6% spodumene concentrate and 428,000tpa of tantalum concentrate at an all-in sustaining cost of US$452/t over the first 10 years of operations.

For another $66m the mine could be ramped up to a 4Mtpa, 658,000tpa spodumene and 587,000tpa tantalum producer, generating free cash flow of $12.2 billion over its life of mine with an NPV of $4.2b and capital payback of 2.3 years.

Unusually when it comes to a WA spodumene mine, Kathleen Valley will be an underground operation, something that ties into the company’s ambitions of reducing the carbon intensity of the mine.

On top of that, Liontown has put out the first numbers a proposed move downstream, a $2 billion lithium refinery which would produce 86,000tpa of lithium hydroxide monohydrate, which the company says would make it the third largest supplier of LHM globally based on Roskill’s projections to 2031.

Did it set the market on fire? Not exactly — Liontown shares are down around 6.7% today so far.

There is something to be said for great expectations.

Liontown Resources share price today:

Plan to lower carbon intensity

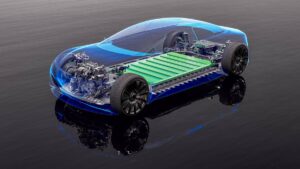

Lithium is of course prized for its use in electric vehicles, an industry expected to grow exponentially between now and 2030 as governments increasingly develop roadmaps and mandates to phase out internal combustion engine vehicles.

The biggest challenge may well be getting the resources to satisfy these projections.

According to Roskill, we could need nine Kathleen Valleys by 2030 to hit global EV targets.

Given this projected scarcity Liontown has assumed a weighted average price of US$1,392/t FOB based on long-term Roskill forecasts.

Higher prices are already being seen now, with fellow producer Pilbara Minerals recently selling spod cargoes at around US$2500/t on its online Battery Materials Exchange platform.

At the 3 month average spot price of US$1822/t, Liontown would be making a healthy margin from Kathleen Valley, increasing its NPV to $6.6 billion, its IRR to 87% and reducing its payback period to just 1.4 years.

Liontown is expected to make an investment decision on the Kathleen Valley mine by the second quarter of 2022, bringing forward its planned date for first spodumene production by a year to the first half of 2024.

That means it will be in negotiations on offtake now.

Part of its pitch will be a pledge to be in the lowest rank of carbon emissions per tonne of spodumene produced.

Liontown plans to do that by launching the mine with 60% renewable energy, including a 13MW plus solar array, wind farm and battery system. The company plans to be at “net zero” by 2034.

Refinery to make Kathleen Valley world’s “third largest” lithium hydroxide supplier

The Liontown brass have spoken more openly in recent months about their plans to become a supplier of downstream lithium chemicals.

Today’s scoping study provides a basis for a downstream PFS, with construction starting potentially as early as 2027.

If Liontown eventually gives the project the go ahead it would join what will by then be a relatively mature WA-based lithium hydroxide industry.

Tianqi and IGO (ASX:IGO) produced the first chemicals in August from their Kwinana plant and expect to hit commercial production next year.

Despite labour shortages delaying its proposed completion to the middle of next year, Albemarle and Mineral Resources (ASX:MIN) are pressing ahead with the development of a refinery in Kemerton near Bunbury.

Wesfarmers and SQM have given the go ahead as well to their own plant in Kwinana, based on feed from the Mt Holland mine near Southern Cross.

Numbers released today by Liontown show a combined mine and refinery project would dwarf a standalone mine in terms of its commercial value but carry a $2b capex tag.

It would have a $9.6bn NPV and generate $32.4bn of life of mine free cash flow at an internal rate of return of 56%, producing 28,800t of LHM per train at an average price of US$29,401/t and operating costs of US$5864/t.

Liontown says at a total capacity of 86,000tpa, it would make the company the projected third largest supplier of LHM in the world by the early 2030s.

“The compelling logic and exceptional financial returns associated with Liontown pursuing a downstream value-adding strategy through integrating the mine concentrator and refinery at Kathleen Valley opens up a truly exciting future,” Liontown MD Tony Ottaviano said.

“Having a clear pathway not only to produce 6% spodumene concentrate at Kathleen Valley but also to participate more substantively in the battery value chain gives Liontown an outstanding position from which to plan our future as a leading integrated global battery materials company.

“The integrated mining concentrate production and refining approach clearly realises much greater value for Kathleen Valley and, importantly, for our stakeholders. As is the Liontown way, we will continue to adopt a disciplined approach to test work, piloting and design, which is evidenced-based.”

Ottaviano said initial precursor work showed Kathleen Valley concentrate would be well suited to be upgraded to a downstream product.

“Having value-added downstream processing on site in the North-eastern Goldfields producing battery-grade products is a very exciting opportunity not just for Liontown, but also for the State of Western Australia – providing an opportunity for us to leverage our world-class resources, people and infrastructure to create a high-value product for the global lithium-ion battery industry,” he said.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.