IXR rebrands magnet recycling subsidiary to Ionic Technologies

Picture: Getty Images

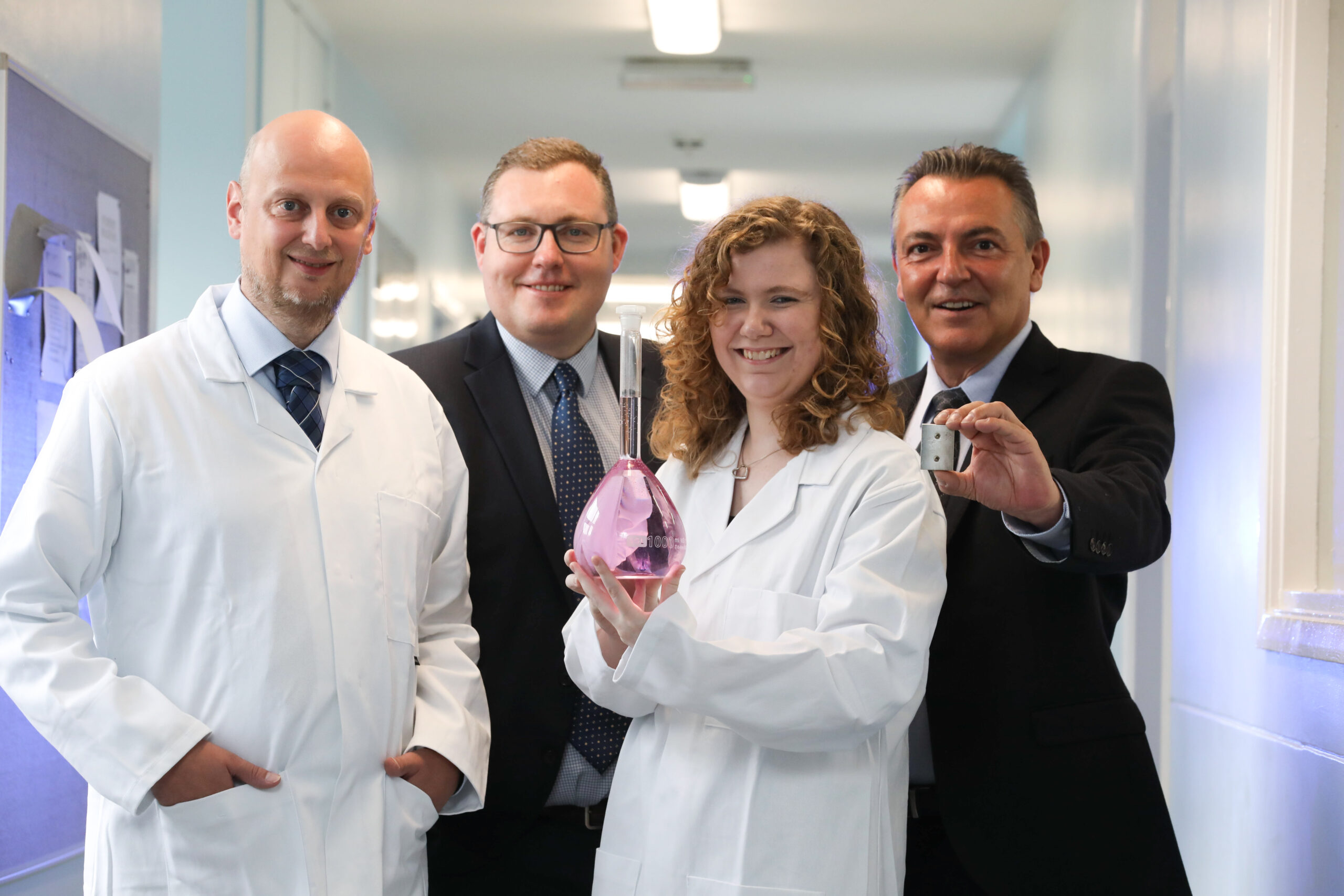

IXR has rebranded its UK subsidiary Seren Technologies to Ionic Technologies to align with its strategy of becoming a sustainable circular economy miner, refiner and recycler of magnet rare earth oxides.

The wholly-owned subsidiary has developed proprietary technology for the separation and recovery of rare earth elements from mining ore concentrates and spent magnets economically and with a minimal environmental footprint compared to competing technologies.

While recycling of magnet REOs currently make up some 40% of the current supply chain, more than 99% of this work is conducted in China.

This means there is a significant market for Ionic Rare Earths (ASX:IXR) and IonicTech to tap into by recycling and refining magnet REOs, providing a secure and traceable solution to providing the inputs, in separated and high purity form, needed to accelerate the world towards carbon neutrality.

Magnet REOs such as neodymium, praseodymium, dysprosium and terbium are essential ingredients for the production of permanent rare earth magnets which are widely used in electric vehicle motors and wind turbines.

Managing director Tim Harrison said the name change will allow the company to build a brand from which to commercialise leading edge, patented technology to help deliver a viable alternative solution for the processing of waste agent and swarf to produce separated and refined REOs to be used in new permanent magnets.

He added that IonicTech aims to provide an alternative to Chinese dominance of the magnet recycling sector with a low cost, modular entry for recycled magnet REOs deployable close to sources of secondary material.

“The circular economy of rare earths will become increasingly more important over years to come, with the current production of magnet rare earths in significant deficit to forecast demand, and with no new supply coming into production, and no new projects in construction today, the deficit is expected to further increase,” he concluded.

Growth of this market is expected to accelerate with Wood Mackenzie forecasting a growth rate around 9% to 2026.

Pilot plant on the cards

IonicTech is currently carrying out test campaigns to be completed over the remainder of 2022.

It was recently awarded a £1.72m ($2.95m) grant towards accelerating the construction of a magnet recycling demonstration plant for the first half of 2023.

This is expected to process 30 tonnes per annum of spent magnets and swarf – fine chips or filings – to produce 10 tonnes per annum of refined and separated permanent MREOs.

This article was developed in collaboration with Ionic Rare Earths, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.