‘Fill the mills’: We took an 800m ride down to see Aurelia Metals’ copper-toned ambitions

The site of the original Cobar copper mine, now a tourist attraction.

Could the Cobar region become “the next Kalgoorlie”? It’s a pretty ambitious thought, overheard by Stockhead on a tour bus from the outback NSW town’s airport to Aurelia Metals sites last week.

The $236 market capped gold and base metals mining and exploration company Aurelia Metals (ASX:AMI) certainly isn’t lacking in ambition, as well as high conviction it’s operating in the midst of a pretty special, minerals-rich, red-earth mining district about 100km southeast of Cobar in central-west NSW.

“We want to be the operator and developer of choice for critical base metals and we believe we’re in a Tier 1 jurisdiction to make that happen,” said the company’s CEO Bryan Quinn to a tour party of mining analysts, investors and a coupla scribes.

Quinn, by the way, is a highly experienced campaigner in the Australian mining industry, having held high-profile exec positions at BHP and Oz Minerals. (See further below for a bit more on Aurelia’s CEO.)

This was the first such tour, including underground visits – one about 800m down – that the company has conducted in about two years. That’s a period in which Aurelia’s share price dipped significantly from about $0.46 in early 2022, falling to $0.08 in August last year, before staging a recovery late 2023 and into this year.

Currently changing hands for about $0.145, AMI’s recent rise has mirrored the buoyancy in the price of gold, which has helped offset lower sales volumes in the down period, primarily at the Peak mine and processing facility but also at the Dargues gold mine, per the company’s recent half-year financial results.

While hardly the Lone Ranger in taking a hit in the Aussie metals market in 2022/23, Aurelia also had to deal with the misfortune of significant rain events over the past three months or so in the Cobar region, which didn’t help matters much.

Various downpours occurred at the company’s Peak, Hera and Federation sites near Cobar, as well as its Dargues site near Braidwood, temporarily affecting production which the company is now dead-eye focused on increasing – amid clearer skies at present this year.

Aurelia’s main game – ‘fill the mills’

We were told “fill the mills” is the catchphrase we’d likely hear Quinn state most often when it comes to the company’s immediate aims. And heard it at least once or twice, we indeed did.

The company’s entire processing infrastructure capacity across its Cobar region sites is about 1.3Mt. With funding, infrastructure, personnel and equipment all in place, and a significant resource base, this all gives the company every reason to believe it’s on the right path to ramp up production and fill those mills.

“Every time we’ve drilled a hole, we’ve pulled something significant out,” the company’s CFO Martin Cummings told Stockhead on the bus drive from Cobar airport to the company’s high-grade Federation project.

So what are they pulling out? As suggested above, the company is a developing, potential polymetallic powerhouse, that has historically been gold heavy, but is transitioning towards a more copper-dominant resource in the mid term, with high-grade zinc (particularly from the Federation site) as well as lead and silver ores.

So what are they pulling out? As suggested above, the company is a developing, potential polymetallic powerhouse, that has been historically gold heavy, but is transitioning towards a more copper-dominant resource in the medium-term, with high-grade zinc (particularly from the Federation site) as well as lead and silver ores.

The Hera underground mine, near Nymagee, ceased commercial production in March 2023, reducing Aurelia’s gold production. That followed the completion of a re-optimisation of the company’s life of mine plan, with only short-term cashflow amelioration deemed possible through Hera.

Hera’s process plant remains on ice – care and maintenance – for now, but a tolling arrangement for its potential use in the future wouldn’t be out of the question, Aurelia’s management told us.

In the absence of a tolling arrangement, refurbishment and restart of the Hera process plant could would only realistically occur once latent capacity at the Peak process plant is fully utilised.

Upsides and downsides for AMI

Aurelia’s is a growth comeback story, so we’ll start low here and finish higher. (Never mind the fact much of the company’s exploration growth is “open along strike, at depth and in all directions”.)

DOWN

• Revenue. The company reported a lower half-yearly revenue in the FY24 H1 compared with the corresponding half’s activity a year ago. At $147.3m, this figure is down about 24% compared with the $192.7m of FY23’s H1.

Most other financial figures for the company, however, are trending in the right direction again, including operating margins – see below.

• In its recent half-yearly report, Aurelia noted that the zinc and lead forecast was “in the lower half of range” and that the zinc realised price was significantly lower this half.

“Treatment and refining costs are higher mainly due to higher zinc treatment charges,” reads the company report.

UP

• The company’s operating margins have seen sustained, material improvement over the half year period ending December 2023, with the group EBITDA (earnings before interest, taxes, depreciation and amortisation) margin, underlying, increasing from 8% to 22%.

• Quality infrastructure, with, among other assets the most versatile polymetallic processing plant in the Cobar Basin at Peak. This is able to treat any ore type in the Cobar basin – zinc, lead, copper, gold – and currently has a capacity of 800ktpa.

• The Peak Mine, built by Rio Tinto, meanwhile, has had 31 years of operation since 1993 and has a tailings storage facility with a life that extends to around 2035 at current processing rates.

It, Stockhead learned on the tour as we circled lower and lower on the tour bus into the mine, extends some 1,500m underground at its deepest. These are proper Jules Verne Journey to the Centre of the Earth levels.

The Peak Mine has 19Mt of Mineral Resources in front of it, including 16Mt of copper resource – we’re talking 1.8% Cu and 0.9g/t Au.

The tour, by the way, included a mobile maintenance workshop some 600m underground – speaking of infrastructure – and the high-grade Chronos lead, zinc, gold deposit, where we saw a production drill and a tele-remote loader in action.

• Superb roads connecting its sites are also among the company’s most crucial infrastructure benefits. This includes the 100km sealed council road and state highway between Federation and Peak – a veritable “production conveyor belt”, Quinn told Stockhead.

The company has invested some $8 million into improving the council-owned stretches of tarmac that it plans to use as activity ramps up in future, including the 8km of Burthong Road between Hera and Federation to support transport of ore mined from the Federation mine to the Peak process plant, where Aurelia will separate zinc and lead-copper concentrates for export.

• The Federation project. In its quest to convert resources to reserves, the high-grade Federation project is a primary focus for the company, with first stope ore production targeted for Q1 FY25.

Federation has a Mineral Resource of 4.8Mt at zinc 9.0%, lead 5.4%, copper 0.3% and gold 0.9g/t.

Heading into the moist-in-places Federation mine, Stockhead was shown the decline development face and an underground diamond drill rig. This was followed by a tour of infrastructure, including recently installed ventilation fans – the reaming of the site’s second and larger fresh air rise, which will provide the air flow to support the site’s future full-scale mining operations.

• Although we didn’t visit it on our tour, Great Cobar is another future growth project for Aurelia, described by the company as “a capital efficient brownfield copper mine development” – important to the company’s mid and longer term aim to become more copper dominant.

Creat Cobar’s most recently published copper Mineral Resource is 8.4Mt at 2.1% Cu, 0.6g/t Au.

It’s a new underground mining area 7km north of the Peak plant, to be accessed via new twin declines from existing underground workings.

Mining and processing of the Great Cobar deposit under the previously published pre-feasibility study was targeting a rate of 500ktpa+. A very high-grade Zn/Pb resource of 0.7Mt has also been identified at Great Cobar.

Why the switch to Aurelia?

Stockhead nabbed a bit of extra time with CEO Bryan Quinn on the journey from the Federation project to the Peak mine and processing facility site.

Quinn had a very long career with BHP – more than 27 years actually, including a series of senior exec roles and a period as president Joint Ventures Americas and Africa and Global Chief of Technical Functions.

The highly regarded mining exec also had a prominent stint at OZ Minerals, heading up its growth, strategy, exploration, sales and marketing businesses.

Stockhead: Bryan, your high-profile mining company background at these huge companies begs the question – why the switch to a comparative junior such as Aurelia Metals? Was it a case of having achieved everything you wanted to at these larger firms?

Quinn: Partly that. I did feel I’d done as much at those companies that I’d wanted to achieve, all the roles I’d wanted to take on.

When the Aurelia job came up, I was already interested in the region and in copper as a resource – CSA and its copper mine is, after all, in the area.

One of the things about OZ Minerals I really liked was the way they built up a very good company around one asset over a period of time. So I see a similarity with what we have at Peak – with cashflow generation to build our business and the future of Federation as a first step.

Stockhead: And the focus for the company’s future is chiefly copper, but also the high-grade zinc?

Quinn: Yeah, definitely, I mean, I look at what commodities I want to be involved with. Copper’s a forward-facing commodity that I think can actually make a difference and that’s something I want to be a part of.

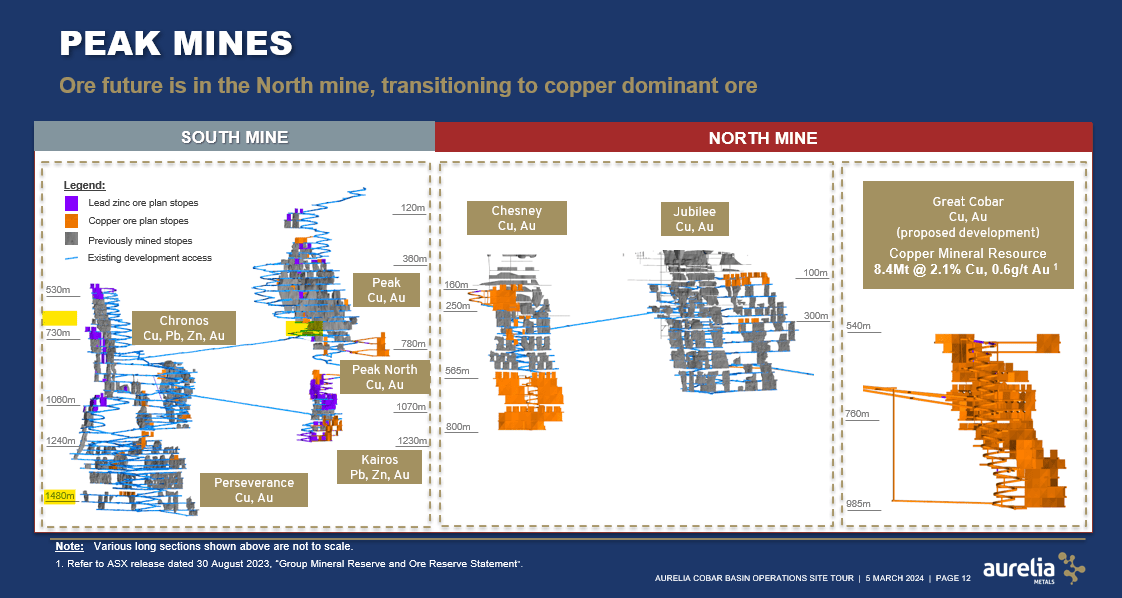

One of the things we’re moving towards at Peak is the South mine having a zinc and lead focus while the North currently has a significantly higher proportion of copper ore, which we’re heading to in general over future years. Then we have Federation, which is more a polymetallic orebody, with lead-zinc and copper-gold.

So realistically, as we go forward, we’ll have multiple mines, multiple operations to draw our ore from and maximise value – which I really think is a bit of differentiator for us in this region.

The high-grade Federation project is something we’re very proud of, from getting it to first hole to where it is today. Developing decline from April 2019 to our first stope haul targeted for Q1 2025, is amazing and a massive milestone.

And to date, we’ve been getting good support from the state government and the Cobar Shire Council as well. So it’s a very big positive for us in terms of how we want to develop and operate this region.

So while we keep generating cash – from Peak and Dargues for now, Peak and Federation will be generating our value in the future to fully fund all our projects.

We’re very much focused on improving what we’ve got. So in terms of performance, we believe there’s more that can be done at Peak, in terms of unit costs in terms of right quality, right volume, hours and rates, equipment.

We’ve got a resource which is getting bigger, so how we convert that into reserves and optimise what we have in terms of infrastructure and resource is really the fundamental stepping stone for us.

Stockhead: Fill the mills?

Quinn: Absolutely – with the right quality material we can become the developer of choice for critical base metals and help turn this organisation into a consistent cash stream.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.