Everest Metals files patent for direct rubidium extraction at Mt Edon

Everest Metals’ patent application validates the extraction process at Mt Edon in WA. Pic: Getty Images

- Everest Metals files patent for DRE, securing intellectual property rights

- Advanced work continues on the engineering scoping study

- Grant funding options to support the next phase of pilot plant construction will be submitted next quarter

Special Report: Everest Metals has taken another step towards securing intellectual property rights for its rubidium recovery process method after filing a provisional application with the government body, IP Australia.

The patent is a result of research undertaken by Edith Cowan University’s (ECU) Mineral Recovery Research Centre (MRRC) and offers an environmentally friendly processing route through direct rubidium extraction (DRE).

Patent attorney firm, Integrated IP, carried out a review of the new process and confirmed the lodgement of the application with IP Australia.

Everest Metals (ASX:EMC) said the new process represents a significant improvement over existing rubidium recovery methods and provides additional advantages to EMC and its Mt Edon critical minerals project.

The patent application also lays the groundwork for future international filings, further bolstering EMC’s intellectual property protection.

Rubidium carbonate currently commands a strong price point at US$1.2m per tonne and EMC is confident the market will see the value in its project as one of the highest-grade stand-alone rubidium deposits in the world – providing exposure to an extremely high value product.

Rubidium recovery rates up to 85%

EMC chairman and CEO Mark Caruso said submitting the patent for the processing flowsheet has marked an important milestone for the company.

“This achievement of a viable process flowsheet to extract rubidium paves the way for progressing commercial and operating engineering studies as well as continuing discussions with potential offtake partners,” he said.

Last year ECU and EMC formalised a partnership by executing a Research Agreement to advance studies on the extraction of rubidium from Mt Edon ore.

The initial phase of the collaboration involved a small-scale laboratory demonstration of the complete process for rubidium recovery.

Cutting-edge methods, including ion exchange, were used during the DRE test work to explore the potential of commercialisation.

Various test work was conducted by ECU’s MRRC with results demonstrating acceptable levels of both rubidium and lithium in the leach liquor.

The initial results reported by EMC in July 2024 demonstrated a technically viable rubidium recovery rate of up to 85% recovery using the DRE method.

Well-endowed geological region

Mt Edon is about 5km2 southwest of Paynes Find, a former gold rush settlement in WA’s Mid West region considered highly prospective for lithium, caesium, tantalum and rubidium mineralisation.

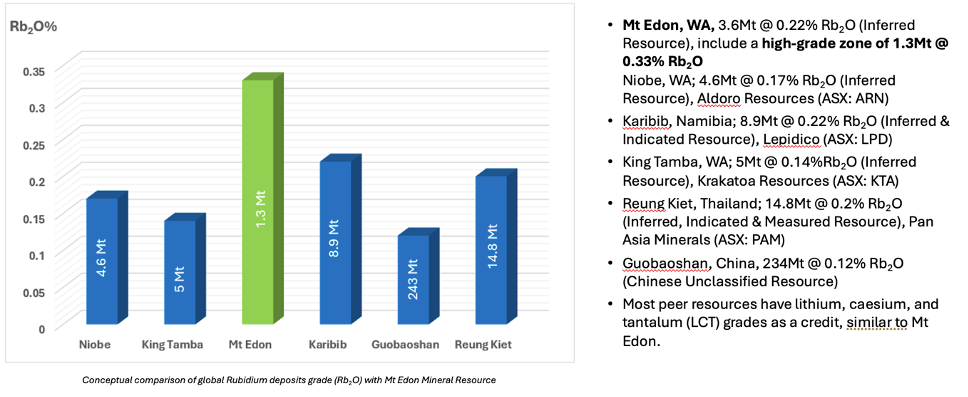

The project is home to a 3.6Mt inferred resource grading 0.22% rubidium and 0.07% lithium which contains more than 7,900t of rubidium.

It contains a higher-grade subset of 1.3Mt at 0.33% rubidium and 0.07% lithium which is nearly 56% of the total contained rubidium tonnes.

What’s coming up?

EMC is now in the planning stages of developing an engineering scoping study, focusing on both capital and operational expenditure, and of transitioning tests from a batch-mode approach to a bench-scale set up.

This change is designed to assist to optimise critical process parameters.

Ultimately, noted EMC, these optimisations should contribute to the development of a comprehensive and effective purification process for future applications.

This article was developed in collaboration with Everest Metals Corporation, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.