Construction of Sovereign’s rutile-graphite pilot phase on schedule

Sovereign Metals is confident it will be able to demonstrate successful land rehabilitation post mining. Pic: via Getty Images.

- Kasiya’s pilot mining and land rehabilitation program underway with site establishment on schedule

- Project is the world’s largest natural rutile deposit and the second-largest flake graphite deposit

- Mobile fleet is currently constructing the test pit, water storage pond and ore stockpile

- Key contractors and consultants across major disciplines have been appointed

Special Report: Sovereign Metals says site construction for the ongoing pilot mining and land rehabilitation program at the Kasiya Rutile-Graphite Project in Malawi is on schedule with groundworks underway.

Kasiya is the world’s largest natural rutile deposit and the second-largest flake graphite deposit.

Sovereign (ASX:SVM) aims to develop the advanced project into a low-CO2, sustainable operation to supply highly sought-after natural rutile and natural graphite to the global markets.

The company is also aiming to restore land after mining to conditions that achieve the same, or better, agricultural yields than existing land uses and crop yields.

‘Ability to execute in Malawi’

The Pilot Phase will demonstrate to local communities the successful rehabilitation of land for agricultural use post-mining.

Plus, the results will also allow Sovereign to determine optimal excavation and backfill approaches, providing critical information for the upcoming Definitive Feasibility Study.

“This Pilot Phase is a step-change for Kasiya and demonstrates our ability to execute in Malawi,” managing director Frank Eagar said.

“The early works are progressing as planned: on schedule and within budget.

“We are very pleased with the progress and specifically how the mobile fleet is performing in the soft saprolite ore, confirming our understanding of how simple mining, with no drilling or blasting required, will contribute to low operating costs.”

Key contractors on board

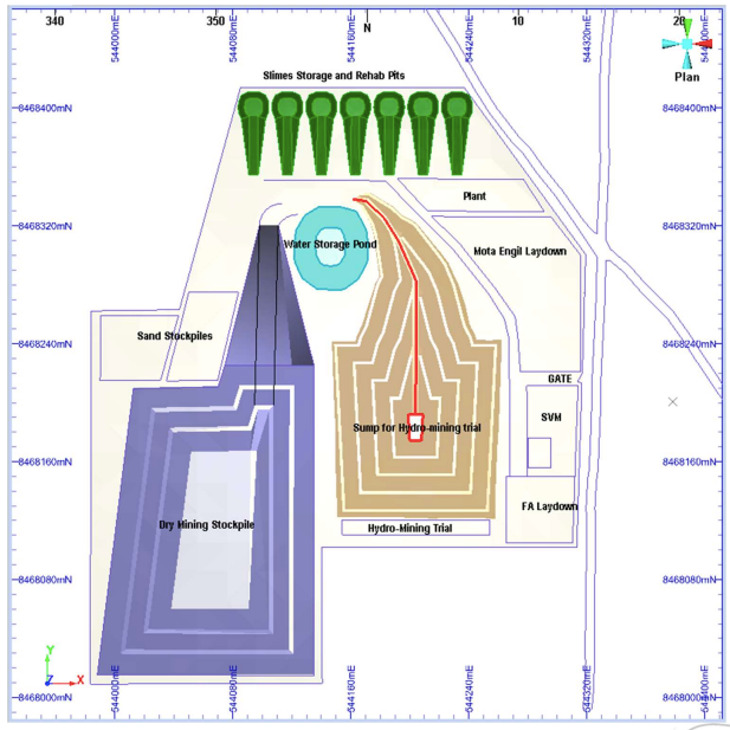

The construction fleet is on-site with groundwork to excavate the water storage pond and construct the test areas currently underway.

Key contractors and consultants have been appointed across all major disciplines essential for the Pilot Phase, including multinational engineering and construction company Mota Engil Group who will perform all excavation required for site establishment, the water storage pond, the test pit, seven rehabilitation pits, site closure and general rehabilitation of the site.

Importantly, the test pit of 120m by 110m will be excavated to a depth of 20m, allowing optimisation of hydraulic and dry mining excavation methods.

In addition, Sovereign will also construct eight small rehabilitation demonstration pits covering a combined area of 100m by 130m which will be used for water storage, excavated material storage, and demonstration of multiple rehabilitation approaches.

This article was developed in collaboration with Sovereign Metals, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.