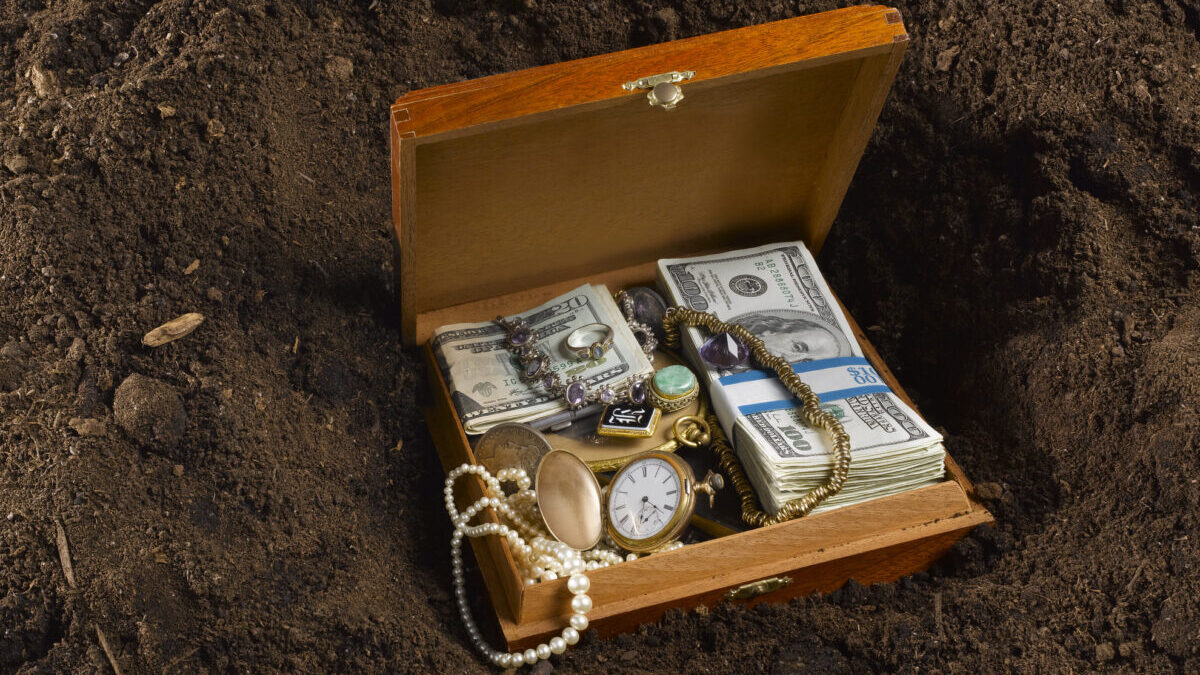

China could hoard its germanium and gallium… are these ASX explorers sitting on hidden treasure?

Pic: Jeffrey Coolidge/Stone via Getty Images

- Germanium and gallium are the metals you never knew you needed

- China wants to restrict their sale and these ASX companies may hold hidden treasure

- Zinc refiner Nyrstar could turn Australia into a big germanium player

After years of wrangling on the critical metals largely produced in China, tech has re-emerged as the vanguard of trade wars and geopolitical tensions between the Middle Kingdom and the West.

The latest salvo from China is its plan to restrict exports of germanium and gallium, two markets where its share of global production capacity is an eye-watering 68% and ~90% according to stats from the US Geological Survey.

In a nutshell, Chinese authorities will need to provide approval to exporters to ship the rare commodities in a move ‘to preserve security and national interests’.

Why are they important? Because they are critical components in semiconductor chips, the building blocks of the technology used in IT, smartphones, computers, EVs and military applications like radars, lasers and spy satellites.

There is a form of tit-for-tat going on here, started by, of all people, the Dutch.

“The Chinese measures come days after the Netherlands announced plans to apply the latest set of controls to limit the sale of high-end chipmaking equipment abroad,” ING noted at the time.

“The move will effectively bar ASML, the Dutch company producing the world’s most advanced semiconductor-making tools, from reaching Chinese companies.

“Japan and the US have also taken steps to limit Chinese companies’ access to chips and chipmaking equipment.

“China is the world-leading producer of gallium and germanium so any restrictions on exports to the rest of the world will likely increase prices for manufacturers or slow down production. Both metals are on the European Union’s list of critical raw materials, deemed ‘crucial to Europe’s economy’.”

Wherefore art thou gallium?

According to the US Geological Survey, the US imports around US$225 million worth of gallium largely in the form of gallium arsenide wafers.

It’s used in the manufacture of semiconductor wafers in integrated circuits, around 74% of the American market, along with light and light sensitive devices like laser diodes, LEDs, photodetectors and solar cells.

That’s most of the rest, with only R & D making up a small 1% sliver of the market. In other words, it is central to everything modern from aerospace to consumer goods, industrial equipment, medical equipment and telecommunications.

From 2018-2021 around 53% of US imports came from where else but China, with 5% from war-stricken Ukraine. Outside of a 13% import share for each of Germany and Japan, 16% came from other smaller sources.

Much of that was high purity refined gallium from scrap, a 290tpa market.

The larger primary low-purity gallium market is heavily concentrated in China. Its 750tpa capacity, a by-product mainly from the processing of bauxite into aluminium, accounts for 86% of the world’s 870t capacity, with China’s stranglehold on the market prompting many loss-making producers to shut down.

There could be over 1Mt of gallium contained in bauxite and zinc resources worldwide. But here’s the kicker – less than 10% could be potentially recoverable.

For germanium, as little as 3% of the by-product contained in zinc concentrates is actually recovered, despite its value in fibre-optics. China exported around 44t of the stuff last year.

So China has the world by the balls on this one. But we also know there’s plenty of latent resources waiting for a more, dare we say, Chinese approach to investment to be unlocked.

Could the panic around security of supply reawaken some sleeping bears?

Who’s in the gallium and germanium game?

There is a reason you hear virtually nothing about gallium and germanium and that is because extracting them as by-products requires the production of zinc or alumina to stack up economically before the commodities come into the picture.

But the recent press around the Chinese export restrictions has many zinc explorers pruning through old data to find a pathway to production.

Micro-cap Mt Burgess Mining (ASX:MTB) was talking up the gallium and germanium potential of its Kihabe-Nxuu project even before the potential Chinese trading restrictions were announced.

Located on Botswana’s border with Namibia, Nxuu has an indicated and inferred resource of 6Mt at 1.8% zinc equivalent, including 64,000t zinc, 32,000t lead, 1.04Moz silver, 2600t vanadium pentoxide, 16t of gallium and 61t of germanium at a 0.5% zinc cutoff.

Kihabe hosts 21Mt at 2% ZnEq, including 321,000t zinc and 154,000t of lead. But MTB has yet to assay there for gallium and germanium.

Its gallium exploration target comes in at a large 75-100Mt at a grade of 9-12ppm or grams to the tonne.

Core samples are in Australia awaiting test work to determine how gallium and germanium can be recovered at Kihabe, with early work showing the mica that contained the gallium and germanium was amenable to flotation, typically resulting in high recovery in a concentrate.

Across the border in Namibia, fellow polymetallic explorer Golden Deeps (ASX:GED) has seen its share price roughly double since announcing it had identified high grade gallium and germanium in drill core at its Nosib project.

It sits 40km from Tsumeb, a historic mine that produced 30Mt of ore containing high grade copper, lead and zinc as well a sprinkling of germanium between 1905 and 1996.

Re-examined drill holes from the Nosib prospect include a copper, lead and vanadium diamond hit containing 8.7m at 128g/t gallium and 11.3g/t germanium from the surface.

Should Golden Deeps be able to identify a market and economic processing route, it could provide valuable by-products. While vanadium, copper and zinc trade at around US$16, US$8 and $US2.50/kg, germanium goes for US$2450/kg and gallium US$230/kg.

“We knew that in the region, the Tsumeb mine, which was a major copper-lead-zinc producer, had also produced about 50 grams per tonne germanium, and that was one of the products they got some value for,” Golden Deeps CEO Jon Dugdale said.

“The value is there, you know, in the sort of 10 to 20ppm or grams per tonne mark for germanium and in the hundreds for gallium, which look to be good and comparable in terms of order of magnitude to some of these other projects that are producing the same sort of stuff.”

The problem in the West

As with many critical minerals, the issue isn’t so much that China boasts the resources other countries don’t.

What it has done is incentivise value-adding in processing, ensuring metals that can be recovered from zinc and alumina refining don’t end up on the scrap heap.

“That’s the biggest impact actually, a lot of people don’t get that,” Dugdale says. “And it’s the same in lithium and it’s the same in say graphite. It’s actually not so much that China mines most of the stuff, it’s that China processes it and makes it into these valuable products.

“So in the case of germanium and gallium, it’s not that they dominate the ore production. It’s that they dominate the downstream processing.

“So the shock to the system is that it’s not set up globally in the germanium and gallium space, but also in the case of graphite and lithium, to be downstream processed to produce the valuable products.

“So what the United States has done is they’ve put in place an incentive scheme for countries like the US and Canada … Australia, other countries that are sort of allies of the US, that they’ll favour production of these downstream products from those countries, but it’s going take them a while to get it all set up.”

Moves are afoot to do just that. Nyrstar, commodity trader Trafigura’s smelting business, has operated a major zinc smelter at Clarksville in Tennessee which has run since 1978.

A study is ongoing into a US$150 million germanium and gallium recovery project that would also increase its zinc production numbers.

“We estimate that the facility would produce as much as 80% of annual US germanium and gallium demand, enhancing US national security, supporting the green transition, and stimulating domestic supply of products currently imported from China,” a spokesperson from Nyrstar said.

“In addition, the project would increase the recovery and production of zinc. We are currently discussing the potential development with relevant government entities in order to finalise the business case and move forward with this investment as soon as practically possible.”

Nyrstar’s Tasmanian zinc business, which includes the Port Pyrie and Hobart smelters, could well become Australia’s first source of the rare metals.

A critical metals white paper last month showed Nyrstar could add processing steps at its Aussie zinc business to produce 7t of germanium and 14-17t of indium annually.

It may not seem like much, but that’s actually 5% of the whole germanium market, meaning it would be a significant contributor to the global supply chain.

European Reunion

The other ASX explorer staking a claim in the germanium and gallium game is Battery Age Minerals (ASX:BM8), which owns the Bleiberg project in Austria.

The project in the Austrian Alps was once a major producer of zinc and lead and at one point was among the largest primary germanium producers globally.

Gallium mineralisation has also been found in historical workings, though it was never extracted by previous owners.

News of the Chinese restrictions was well-timed for Battery Age, primarily focused on the Falcon Lake lithium project in Ontario, Canada.

It pegged additional extensions to the west-northwest of Bleiberg’s historic workings, a move that could prove to have real strategic potential in light of China’s trade attack.

““We are pleased to have secured additional ground adjacent to our existing Bleiberg Zinc-Lead-Germanium Project,” BM8 MD Gerard O’Donovan said last week.

“Based on our early desktop studies and a site visit, we have identified additional prospective land which merited strategic expansion of our claims.

“We now look forward to progressing exploration activities over the coming months to evaluate the potential of this Project for our shareholders.”

Germanium and gallium hopefuls share price today:

At Stockhead, we tell it like it is. While Battery Age Minerals is a Stockhead advertiser, it did not sponsor this article.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.