‘Beyond expectations’: Ark Mines’ Sandy Mitchell rare earths project has the right stuff with metallurgical success

Results have exceeded AHK’s expectations and move Sandy Mitchell further along the development pathway. Pic via Getty Images

- Beneficiation test work has produced a high commercial grade rare earth concentrate with excellent recoveries at Sandy Mitchell

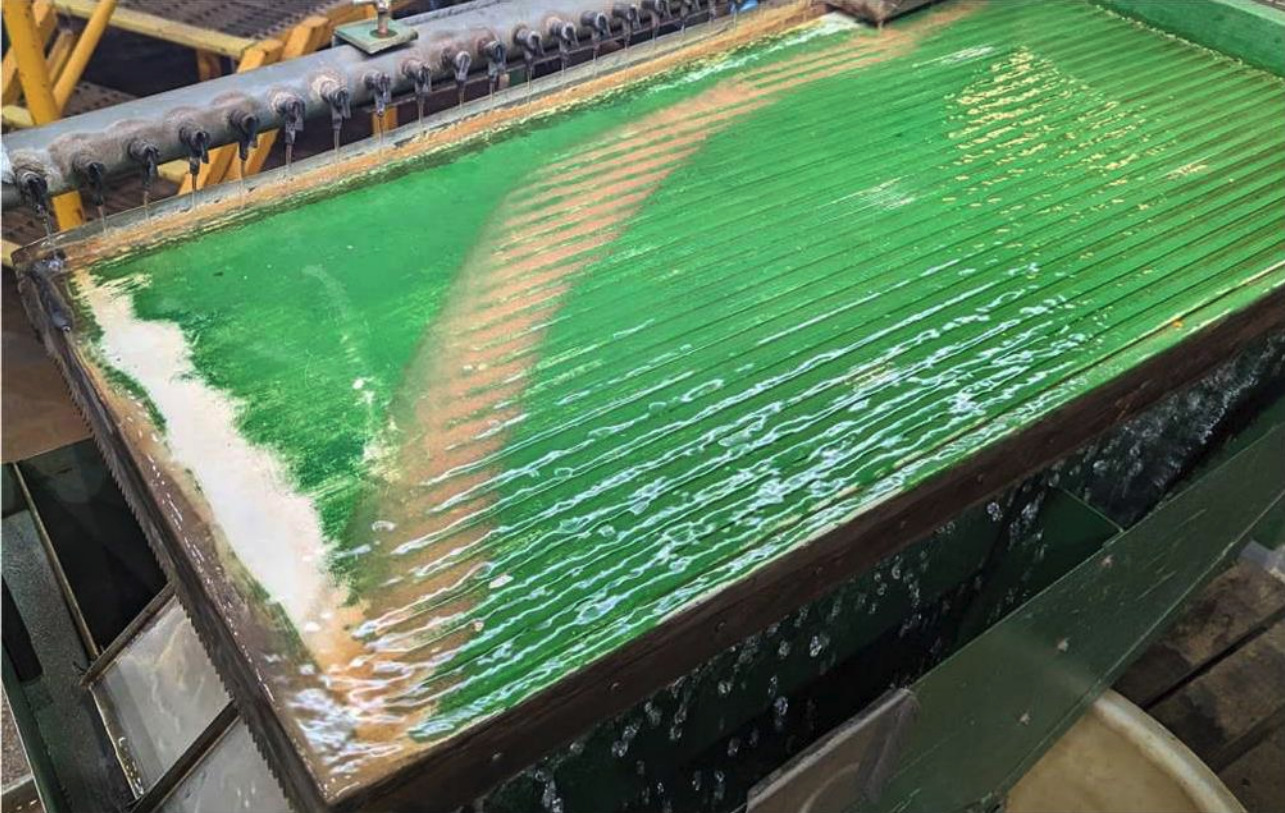

- Test work shows the greatest upgrade is by simple gravity separation, confirming the material is amenable to straightforward beneficiation by water-only, low-cost gravity processing

- Phase 2 drilling is ongoing with two rigs operating to extend depths to ~24m

Special Report: Ark Mines is moving its Sandy Mitchell rare earths project further along the development pathway after producing a high commercial grade rare earth concentrate with excellent recoveries during beneficiation test work.

First pass water-based beneficiation test work at Ark Mines’ (ASX:AHK) Sandy Mitchell rare earths project in North Queensland has confirmed the material at the project is amenable to straight forward, low-cost gravity processing after producing a commercial grade concentrate.

The final concentrate assays returned 51.9% TREO (519,000ppm), and contained mostly lanthanum, cerium, praseodymium, and neodymium – as well as heavy rare earths (dysprosium and terbium) – which collectively represent a high value saleable product.

Direct cerium oxide (CeO2) recovery from gravity feed to REM concentrate is estimated to be 71.7%. However, test work calculated that in a normal recirculating gravity plant, overall recovery of 83.8% may be achieved.

In cerium oxide recovery, the CeO2 content is used as a tracer for the rare-earth bearing mineral monazite which was subsequently upgraded from 0.04% in the as-received feed, to 23.6% in the cleanest product.

Results to be incorporated into scoping study

AHK executive director Ben Emery says these results raise the excitement on what is already a very encouraging project, given that these “excellent” first stage beneficiation results were achieved with directly recovered air core samples.

“The samples had no mechanical or chemical separation processing before the initial pre-screen to reject oversize +2mm material, and the results achieved are well beyond our expectations,” he says.

“Importantly, the first pass beneficiation test work showed that the highest REE extraction grades were achieved by simple gravity separation, confirming a key value add of this project.

“As well as the lowest-cost option from a capex perspective, beneficiation by gravity processing also has the lowest environmental impact and doesn’t involve the use of any chemicals.

“We look forward to providing more updates as the metallurgy program advances, the results of which will be incorporated into a scoping study ahead of a planned Pre-Feasibility Study for the Sandy Mitchel project.”

Phase 2 drilling ongoing

Metallurgical test work with expert independent processing firm, Mineral Technologies, remains ongoing with final results to be incorporated into a scoping study at Sandy Mitchell ahead of a planned pre-feasibility study.

In conjunction, AHK is in the process of completing Phase 2 drilling, which will yield further samples for larger bulk metallurgical testing.

This will include further proof of mineralogy and beneficiation by conventional techniques such as gravity separation and electrostatic magnetic separation.

“We expect to soon be able to further communicate the project’s commercial benefits – not just for rare earths but also for heavy minerals that also have considerable value,” Emery said.

This article was developed in collaboration with Ark Mines, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.