Australian Mines is one step away from its big battery metals play – and investors are ready to pounce

Pic: Tyler Stableford / Stone via Getty Images

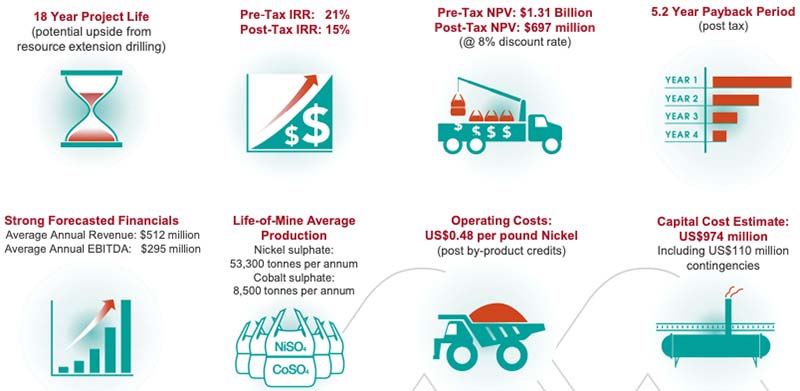

Australian Mines’ mammoth Sconi battery metals project in Queensland will make profits of $2.6 billion over an initial 18-year life, a Bankable Feasibility Study (BFS) shows.

Miners undertake up to four different types of studies when examining whether or not a resource can be mined economically – and the bankable feasibility (BFS) is the most comprehensive of the lot.

Following a 2-year construction period — followed by a 2-year ramp up — the $1 billion processing plant will produce 9,898 tonnes of cobalt sulphate and 70,894 tonnes of nickel sulphate each year.

The share price of Australian Mines (ASX:AUZ) improved 3.3 per cent to 6.2c on the news, but Sconi start-up costs of over $1.3 billion made investors wary.

The market is waiting for Australian Mines to finalise project funding through a combination of debt and equity before it gets too excited.

The company wants to get funding locked in and then kick off construction in 2019, with the first export to Korean offtake partner SK Innovations’ European electric vehicle (EV) battery plant slated for 2022.

Work by financial advisor Medea Capital Partners showed up to 60 per cent of financing – or $803 million – can be secured from Australian based commercial lenders, Australian Mines told investors.

“Medea is currently in initial discussions with several Australian based commercial lenders in relation to providing additional senior secured debt funding as part of the overall US$585 million ($803 million) debt facility for the Sconi project,” the explorer said.

“The Australian Mines Board believes that a syndicate of between 6 to 8 lenders (including NAIF) will be sufficient to fully fund the debt facility.”

Australian Mines is currently providing detailed due diligence materials to the $5 billion Northern Australia Infrastructure Facility (or “NAIF”) for review, before submitting a formal investment proposal.

- Subscribe to our daily newsletter

- Bookmark this link for small cap news

- Join our small cap Facebook group

- Follow us on Facebook or Twitter

Australian Mines is also examining other forms of funding, including the possibility of offtake pre-payments from SK Innovation.

In February, the company signed a 7-year binding offtake agreement with SK Innovation for all cobalt and nickel produced.

SK Innovation needs long-term nickel and cobalt to supply its global electric vehicle battery manufacturing plants.

A new long-term deal to supply EV batteries to leading carmaker Volkswagen Group was signed just this month.

VW selects SK Innovation as fourth major EV battery cells supplier https://t.co/6AOhQLrstm pic.twitter.com/vFfOKUcSvd

— Electric Cars Report (@ECarsReport) November 13, 2018

Volkswagen reckons it needs battery capacity in excess of 150GWh per year through to 2025 just to equip its own electric fleet — that’s equal to the annual battery cell capacity of more than four Tesla Gigafactories.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.